Preparation method of modified phenolic resin based anti-glare panel

A phenolic resin, anti-glare board technology, applied in flat products, applications, household appliances, etc., can solve the problems of secondary damage, easy aging, increased maintenance costs, etc., to achieve uniform stress at the interface, good anti-aging performance, The effect of the best corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

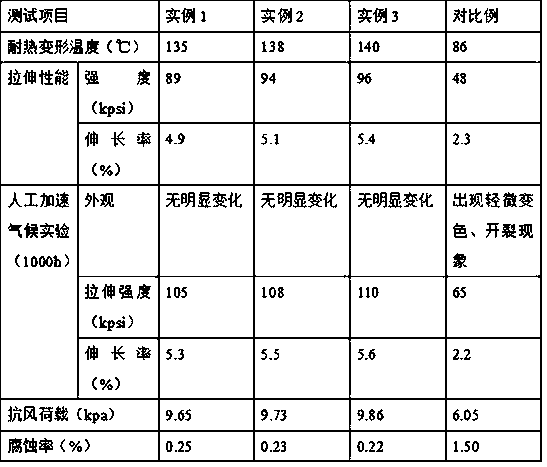

example 1

[0025]According to the mass ratio of 5:2:1, mix phenol, deionized water and sodium hydroxide solution with a mass fraction of 40% and pour it into the reaction kettle, and stir for 8 minutes at a speed of 160r / min to obtain a stirred liquid, and then Add the mass fraction of 5% of the volume of the stirring liquid to the stirring liquid, which is a 35% formaldehyde solution, and stir and react at a temperature of 80° C. for 23 minutes to obtain a reaction solution 1; Mix 40% sodium hydroxide solution in a mass ratio of 4:1:2 and put it in a beaker, heat up to 90°C, keep it warm for 18 minutes, cool and discharge to obtain self-made phenolic resin; Ethyl acetate and silane coupling agent KH-560 were mixed and stirred for 8 minutes to obtain a stirred liquid, then the stirred liquid, absolute ethanol and hydrochloric acid with a mass fraction of 30% were mixed in a mass ratio of 8:1:1, and the temperature was Stir and catalyze at 36°C for 20 minutes to obtain a catalytic solutio...

example 2

[0027] According to the mass ratio of 5:2:1, mix phenol, deionized water and sodium hydroxide solution with a mass fraction of 40% and pour it into the reactor, and stir for 9 minutes at a speed of 170r / min to obtain a stirred liquid, and then Add the mass fraction of 5% of the volume of the stirring liquid to the stirring liquid to be a 35% formaldehyde solution, and stir and react at a temperature of 83° C. for 25 minutes to obtain a reaction liquid 1; Mix 40% sodium hydroxide solution in a mass ratio of 4:1:2 and put it in a beaker, heat up to 93°C, keep it warm for 11 minutes, cool and discharge to obtain self-made phenolic resin; Ethyl acetate and silane coupling agent KH-560 were mixed and stirred for 9 minutes to obtain a stirred liquid, then the stirred liquid, absolute ethanol and hydrochloric acid with a mass fraction of 30% were mixed in a mass ratio of 8:1:1, and the temperature was Stir and catalyze at 38°C for 21 minutes to obtain a catalytic liquid, then mix and...

example 3

[0029] According to the mass ratio of 5:2:1, mix phenol, deionized water and sodium hydroxide solution with a mass fraction of 40% and pour it into the reaction kettle, and stir for 10 minutes at a rotational speed of 180r / min to obtain a stirred liquid, and then Add the mass fraction of 5% of the volume of the stirring liquid to the stirring liquid, which is a 35% formaldehyde solution, and stir and react at a temperature of 85° C. for 27 minutes to obtain a reaction solution 1; Mix 40% sodium hydroxide solution in a mass ratio of 4:1:2 and put it in a beaker, raise the temperature to 95°C, keep it warm for 24 minutes, cool and discharge to obtain self-made phenolic resin; Ethyl acetate and silane coupling agent KH-560 were mixed and stirred for 10 minutes to obtain a stirred liquid, then the stirred liquid, absolute ethanol and hydrochloric acid with a mass fraction of 30% were mixed in a mass ratio of 8:1:1, and the temperature was Stir and catalyze at 42°C for 22 minutes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com