Pipeline leakage detector probe electric cable connection circuit

A cable connection and detector technology, which is applied to pipeline systems, instruments, measuring devices, etc., can solve problems such as maintenance, maintenance costs, fragility, and detection failure, and achieve a reliable effect of pipeline corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

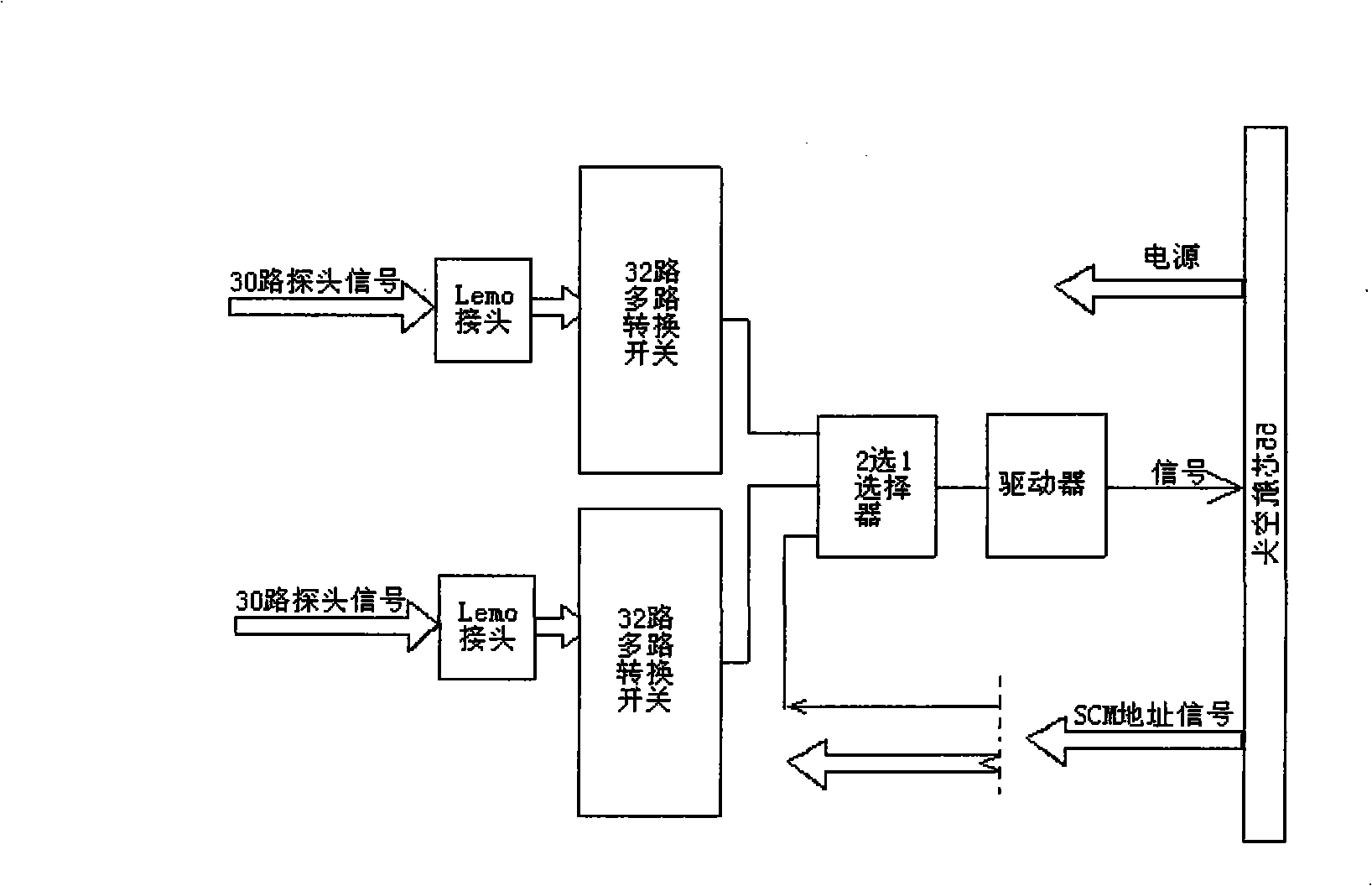

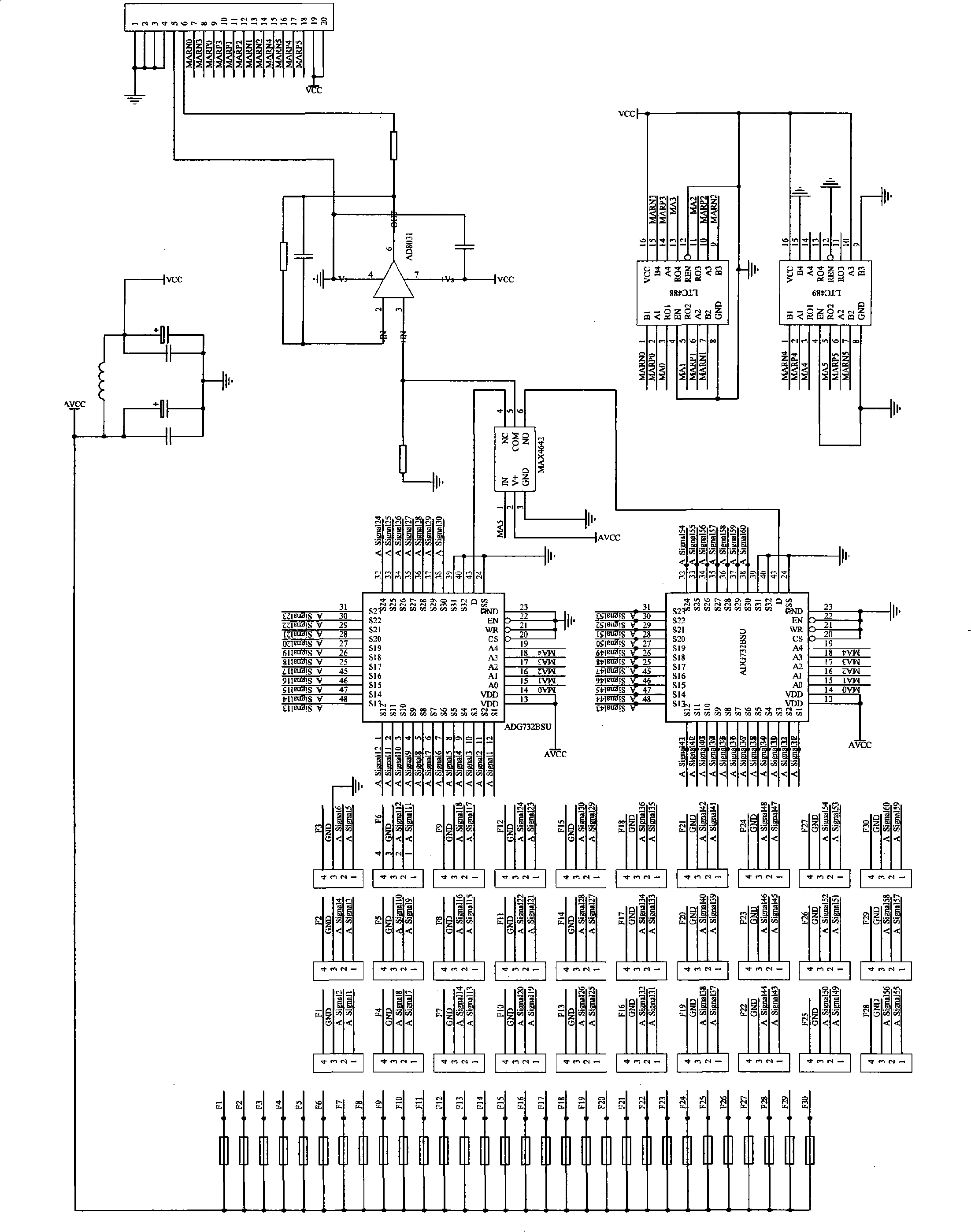

[0016] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental circuit for the probe cable connection circuit of the Φ1016mm high-definition pipeline magnetic flux leakage corrosion detector, and its principle block diagram is as follows figure 1 As shown, the electrical schematic diagram is shown as figure 2 shown. The probe signal concentration module is a 32-way multiplex switch, ADG732BSU is selected, the 2-to-1 selector is MAX4624EZT-T, and the driver is AD8031AR. The circuit connection of every 30 probes is as follows: figure 2 , the DC power supply AVCC is connected to the F1-F30 terminals of 15 double probes through 15 insurances connected in parallel, the GND terminals of 15 double probes are grounded, and the two output terminals A Signal of 15 double probes are connected to 32 channels in total. The S1-S30 terminals of the switch ADG732BSU, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com