Water-based polyurethane anti-glare coating material and preparation method thereof

A technology of water-based polyurethane and coating materials, which is applied in the direction of polyurea/polyurethane coatings and coatings, can solve the problems of complex preparation process and industrialization to be improved, and achieve uniform distribution, increased dispersion and storage stability, and anti-corrosion. Corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042](1) Put 94.08g of polytetrahydrofuran diol (PTMG-1000, 1000g / mol) and 3.90g of 2,2-dimethylolpropionic acid after dehydration into the reaction kettle at room temperature, drop 0.05g of dihydrofuran Dibutyltin laurate catalyst, after stirring evenly, add 52.02g of isophorone diisocyanate (control R value 1.9:1) for prepolymerization reaction: first gradually raise the temperature to 60°C, react for 1.5h; then continue to heat up to 80°C , Reaction 2.5h. During the reaction, the remaining NCO group content was determined to be constant by di-n-butylamine method. The prepolymer was cooled to about 40°C.

[0043] (2) Add 2.94 g of triethylamine to the product obtained in step (1), neutralize to form a salt for 10 minutes, and further cool to 30° C.

[0044] (3) Pour the product of step (2) into 409.00 g of sodium ethylenediamine ethyl sulfonate aqueous solution with a mass concentration of 2.73%, emulsify and extend the chain for 15 minutes, and the stirring rate is 3000 ...

Embodiment 2

[0054] (1) Put 87.32g of PTMG-1000 and 5.34g of 2,2-dimethylolbutanoic acid after dehydration treatment in the reaction kettle at room temperature, drop in 0.15g of dibutyltin dilaurate catalyst, stir well, add 52.02g of isophorone diisocyanate (control R value 1.9:1) for prepolymerization: first gradually raise the temperature to 65°C, react for 1.0h; then continue to raise the temperature to 82°C, react for 2.0h. During the reaction, the remaining NCO group content was determined to be constant by di-n-butylamine method. The prepolymer was cooled to about 50°C.

[0055] (2) Add 4.17 g of tripropylamine to the product of step (1), neutralize to form a salt for 15 minutes, and further cool to 25°C.

[0056] (3) Pour the product of step (2) into 222.50 g of sodium ethylenediaminoethylsulfonate aqueous solution with a mass concentration of 7.00%, emulsify and extend the chain for 20 minutes, and the stirring rate is 1800 rpm.

[0057] (4) At a stirring rate of 1000 rpm, 2.19 g...

Embodiment 3

[0060] (1) Put 102.24g of PTMG-1000 and 3.90g of 2,2-dimethylolpropionic acid after dehydration treatment in the reaction kettle at room temperature, drop in 0.09g of bismuth isooctanoate catalyst, stir well, add 43.86g Prepolymerization of isophorone diisocyanate (control R value 1.5:1): first gradually raise the temperature to 55°C, react for 1.5h; then continue to raise the temperature to 80°C, react for 2.5h. During the reaction, the remaining NCO group content was determined to be constant by di-n-butylamine method. The prepolymer was cooled to about 40°C.

[0061] (2) Add 1.02 g of ammonia water to the product of step (1), neutralize to form a salt for 10 minutes, and further cool to 30°C.

[0062] (3) Pour the product of step (2) into 504.00 g of sodium ethylenediamine ethylsulfonate aqueous solution with a mass concentration of 0.50%, emulsify and extend the chain for 15 minutes, and the stirring rate is 3000 rpm.

[0063] (4) At a stirring rate of 800 rpm, 6.63 g of...

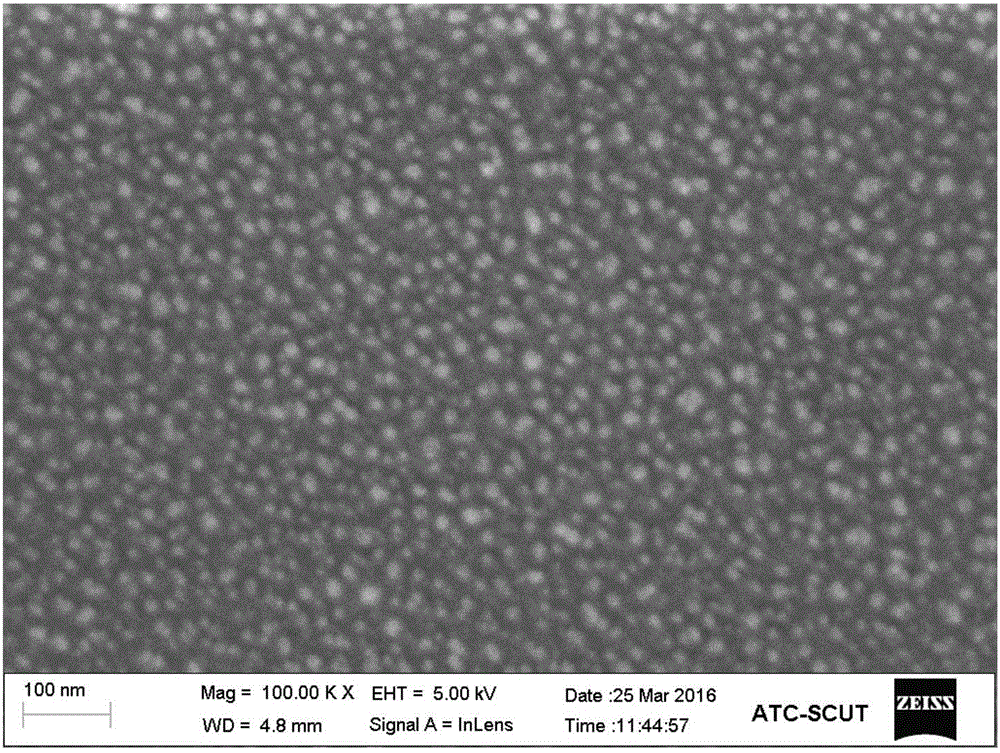

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com