Self-healing cement-based material containing bacterial spores and preparation method thereof

A technology of cement-based materials and bacterial spores is applied to concrete with self-healing function of cracks, self-healing cement-based materials and their preparation, mortar and similar building materials, and can solve the problem of limited self-healing ability and self-healing. Slow speed, inability to meet and other problems, to achieve the effect of reducing water penetration speed, strong resistance, and improving structural durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention further discloses a preparation method of a self-healing cement-based material added with bacterial spores, comprising the following steps:

[0018] (1) Weigh the required cement, weigh and add calcium lactate in proportion, and stir until the calcium lactate is evenly distributed in the cement;

[0019] (2) Replace part of the mixing water with the spore suspension and shake the remaining required water together, then pour it into cement and calcium lactate, stir it evenly, and pour it into the mold for molding.

Embodiment 1

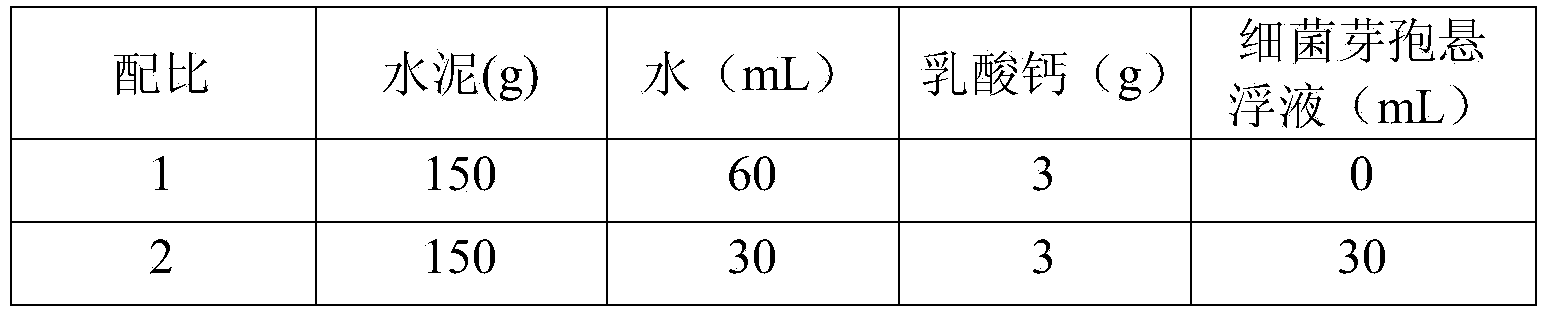

[0022] Embodiment 1: prepare two groups of test pieces by the test piece mixing ratio in table 1, water and cement mass ratio are 0.4, calcium lactate quality is 2% of cement quality, and proportioning 1 is benchmark group, does not add bacterial spore, will The weighed cement (P.O.42.5 cement), calcium lactate and water are mixed evenly and put into the mold; the proportion 2 is added with bacterial spores (108 spores are added to the cement-based material per cubic centimeter), and the weighed cement ( After P.O.42.5 cement) and calcium lactate are dry mixed evenly, replace part of the mixing water with the spore suspension and shake the remaining required water together, then pour it into the cement and calcium lactate, mix well and put it into the mold for molding. After forming, blow the surface of these two groups of test pieces with warm air immediately to make them produce plastic shrinkage cracks of 0.4-0.5mm. After 24 hours, measure the initial water seepage velocity ...

Embodiment 2

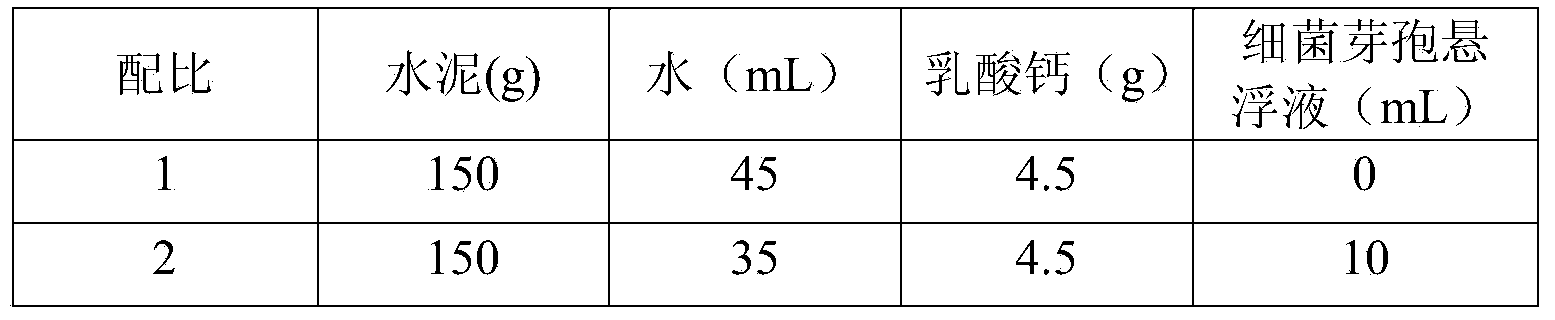

[0028] Embodiment 2: prepare two groups of test pieces by the test piece mixing ratio in table 3, water and cement mass ratio are 0.3, and calcium lactate quality is 3% of cement quality, and proportioning 1 is benchmark group, does not add bacterial spore, will The weighed cement (P.O.42.5 cement), calcium lactate and water are mixed evenly and then put into the mold; the ratio 2 is added with bacterial spores (3.3×10 per cubic centimeter of cement-based material) 7 spores), the weighed cement (P.O.42.5 cement) and calcium lactate are dry mixed evenly, and the spore suspension is replaced with part of the mixing water and the remaining water is shaken together, then poured into the cement and calcium lactate, and stirred. After uniformity, put it into the mould. After 24 hours of molding, demould, artificially create 0.4-0.5mm cracks on a three-point bending test machine, and then cure the cracked specimens in water, observe and record the self-healing conditions of cracks 7d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com