System for effectively controlling erosion of glass melting furnace

A technology for controlling glass and melting furnaces. It is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of lack of series device monitoring, affecting glass quality, and difficult maintenance, so as to benefit the cost of glass and improve the quality of glass. Effects of improving quality, yield, and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

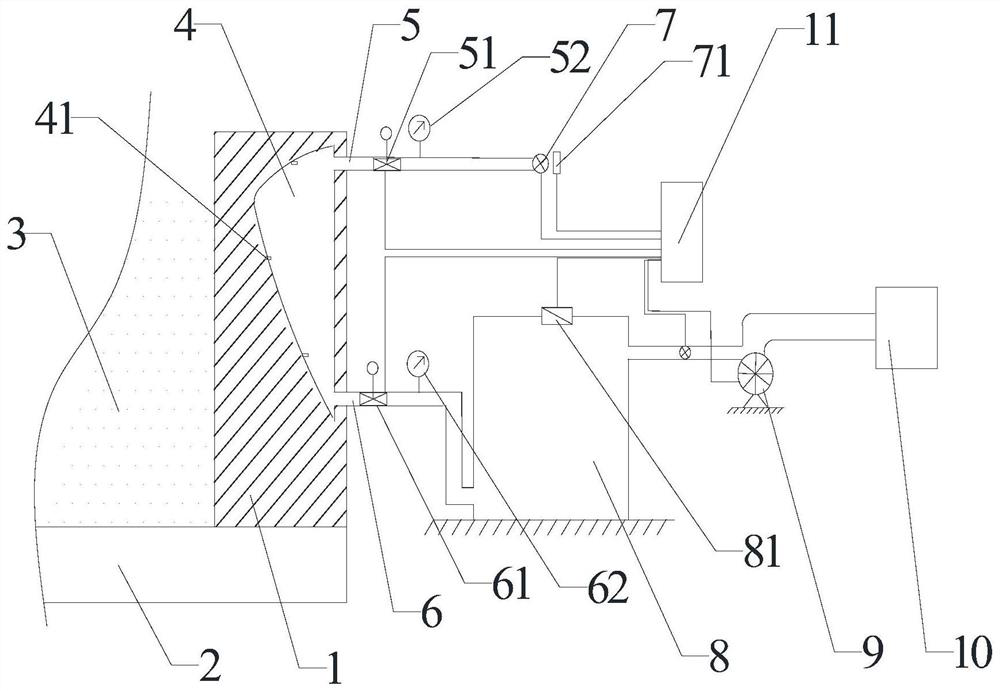

[0038] see figure 1 , a system for effectively controlling the erosion of a glass melting furnace, comprising a melting furnace body and a cooling device; the melting furnace body contains a molten glass 3, which includes a pool bottom brick 2, a pool wall brick 1 and a pool wall brick 1 Internal cooling chamber 4;

[0039] The side wall of the cooling chamber 4 is arc-shaped recessed toward the junction of the liquid glass scouring liquid level in the glass melting furnace and the pool wall brick 1, and the cooling chamber 4 is located between the side wall and the plane where the glass liquid scouring liquid level is located. The inner side wall of the pool wall brick 1 has the shortest distance, and the distance between the side wall of the cooling chamber 4 and the inner side wall of the pool wall brick 1 gradually increases with the plane where the glass liquid scours the liquid surface as the boundary to the upper and lower sides; The cross-sections of each height in th...

Embodiment 2

[0046] see figure 1 , a system for effectively controlling erosion of a glass melting furnace, comprising a melting furnace body and a cooling device; the melting furnace body includes a pool wall brick 1 and a cooling chamber 4 arranged inside the pool wall brick 1;

[0047] The side wall of the cooling chamber 4 is arc-shaped recessed toward the junction of the liquid glass scouring liquid level in the glass melting furnace and the pool wall brick 1, and the cooling chamber 4 is located between the side wall and the plane where the glass liquid scouring liquid level is located. The inner side wall of the pool wall brick 1 has the shortest distance, and the distance between the side wall of the cooling chamber 4 and the inner side wall of the pool wall brick 1 gradually increases with the plane where the glass liquid scours the liquid surface as the boundary to the upper and lower sides; The cross-sections of each height in the horizontal direction of the cooling chamber 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com