Electric cable well

A cable well and cable technology, applied in the field of cable wells, can solve the problems of electric danger, non-compliance with environmental protection policies, multiple safety, etc., and achieve the effects of saving maintenance and safety issues, facilitating standardized production, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail and completely below in conjunction with the embodiments and accompanying drawings.

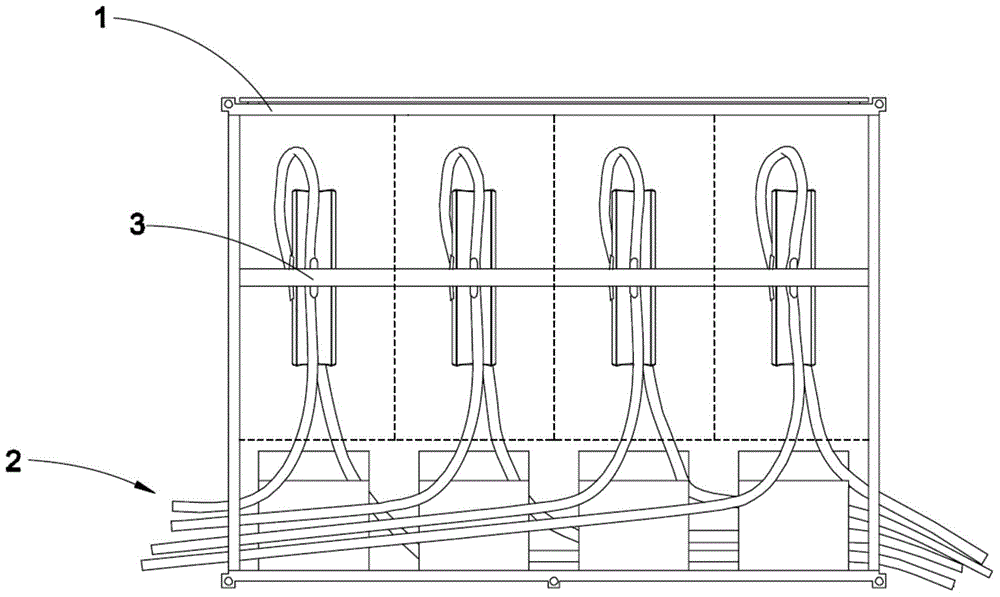

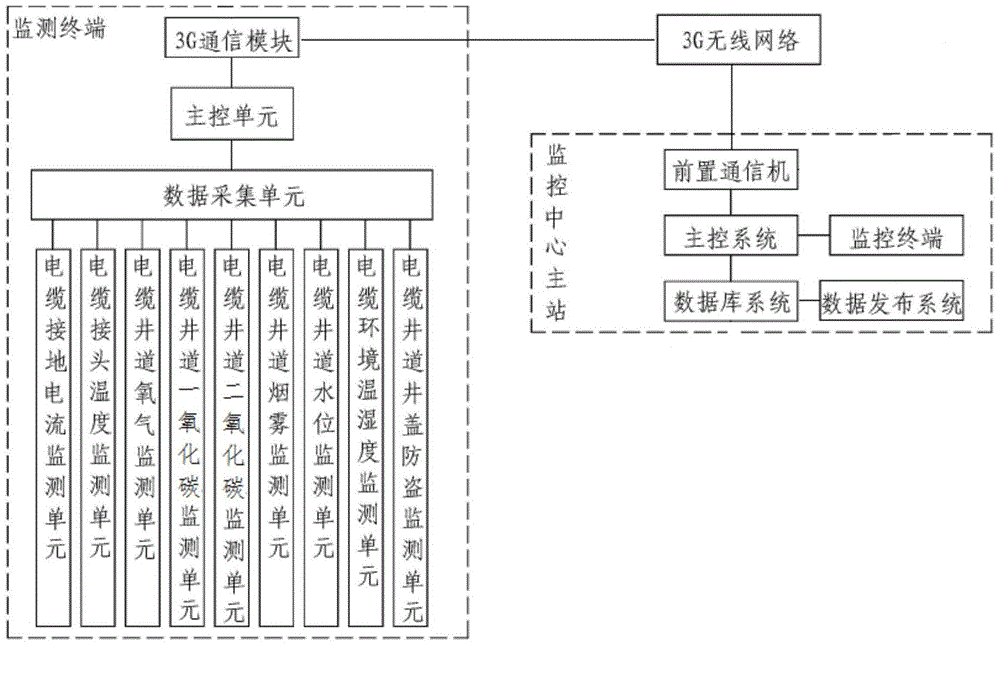

[0034] The cable shaft includes a body 1 and a cable 2 in the body, wherein the cables are independently distributed in the cable shaft; when there are multiple cables, each cable is independently at least parallelly distributed in the cable shaft; The body is placed vertically in a single circuit; every two cables pass through a spacer 3 to divide the cable well into two vertical spaces for accommodating cables; when there are n cables, the number of spacers in the cable well is n- 1. The cable shaft also includes an intelligent online monitoring and early warning system for cable operating conditions, including a monitoring terminal and a monitoring center master station. The monitoring terminal is set at the cable site and connected to the monitoring center master station through a wireless network.

[0035]The monitoring ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com