Anti-icing starter solenoid switch with braided copper contacts

An electromagnetic switch, anti-icing technology, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve the problems of electromagnetic switches not conducting circuits, unable to reliably prevent icing, and starters failing to start normally. Solve the problem of unable to start normally, avoid icing, and have good anti-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

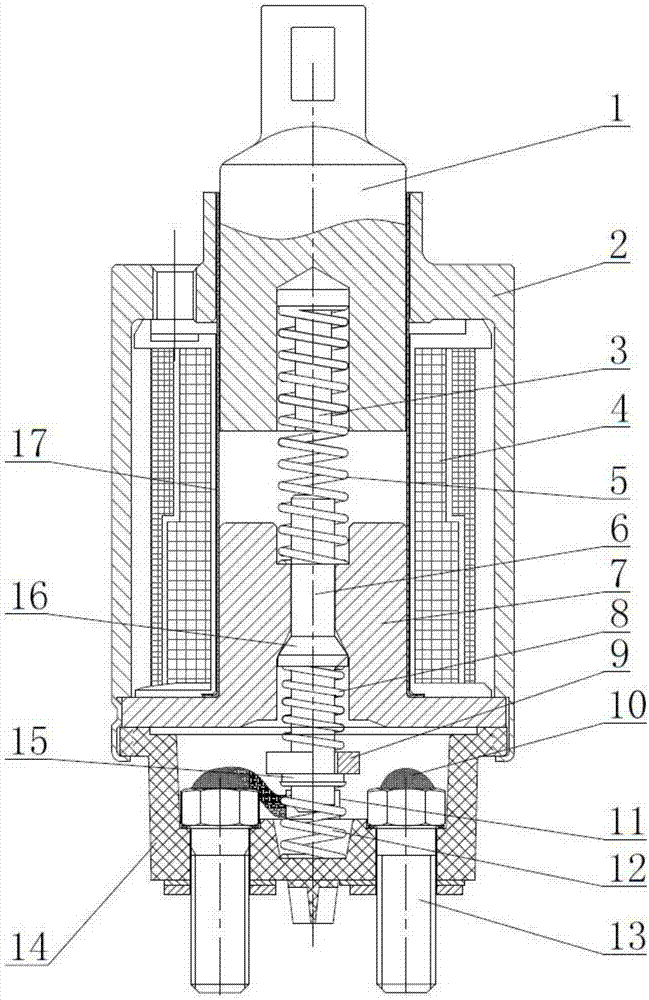

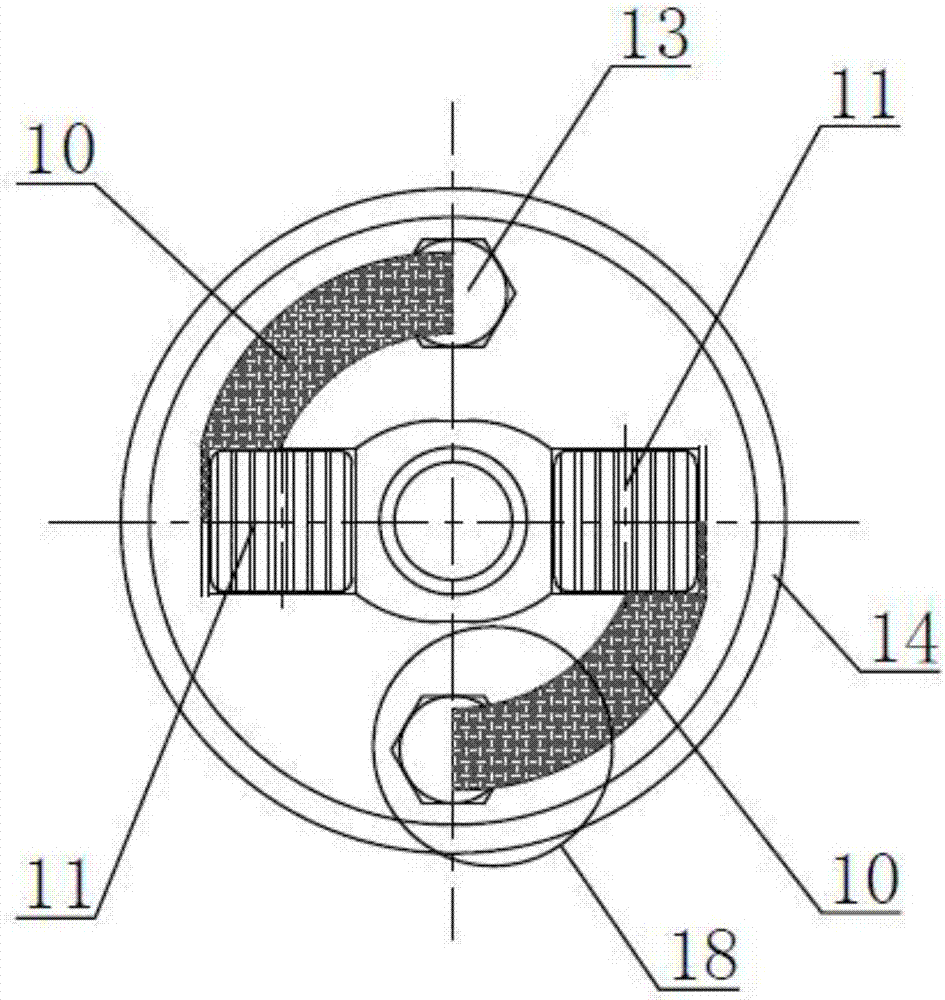

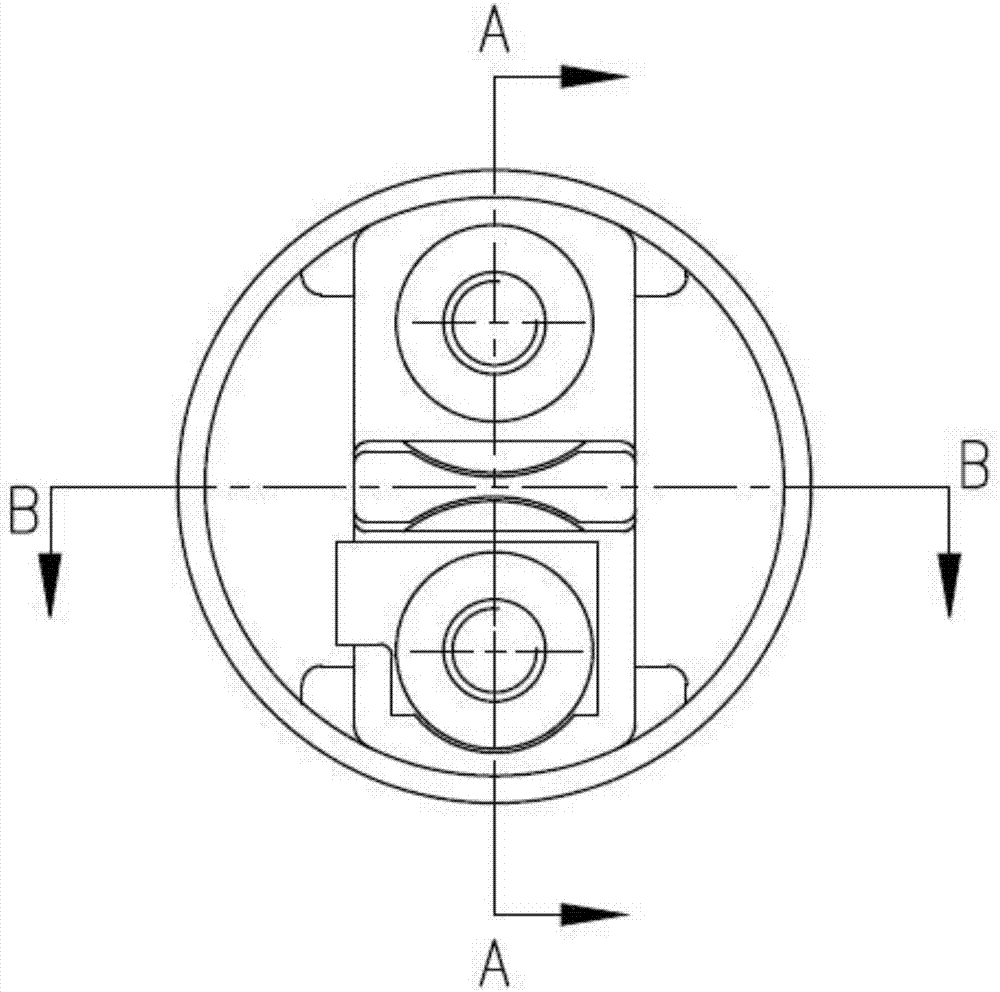

[0036] Such as Figure 1-Figure 5 As shown, the anti-icing starter electromagnetic switch with braided copper contacts includes a housing 2, a static contact seat 14 located at the bottom of the housing 2, two wiring terminals 13 located in the static contact seat 14, a fixed The ring-shaped support limit seat 7 above the static contact seat 14, the movable contact rod 6 set in the center of the ring-shaped support limit seat 7, the movable contact rod 6 arranged at the lower end of the movable contact rod 6 and perpendicular to the movable contact rod 6 Sheet 9, the return spring 12 set between the lower end of the moving contact rod 6 and the bottom surface of the static contact seat 14, the sleeve 17 set on the outer periphery of the upper part of the annular support limit seat 7, and the sleeve 17 formed by the shell 2 The electromagnetic coil 4 in the annular space, the moving iron core 1 that is located on the top of the annular support limit seat 7 and can slide along t...

Embodiment 2

[0040] Such as Figure 6 As shown, in the anti-icing starter electromagnetic switch with braided copper contacts, the terminal 13 is composed of a screw 1301 and a radiator 1302 arranged on the top of the screw 1301 . The radiator 1302 is composed of a bottom plate 1302a and a plurality of parallel vertical fins 1302b evenly distributed on the upper surface of the bottom plate 1302a, and the copper braid 10 is connected to the top of the vertical fins 1302b. When the external air temperature of the electromagnetic switch drops due to the weather, water vapor will condense on the radiator 1302 and the part of the copper braid 10 close to the radiator 1302 . Others are the same as embodiment 1.

Embodiment 3

[0042] Such as Figure 7 As shown, in the anti-icing starter electromagnetic switch with braided copper contacts, the terminal 13 is composed of a screw 1301 and a radiator 1302 arranged on the top of the screw 1301 . The radiator 1302 is composed of a bottom plate 1302a, a plurality of parallel vertical fins 1302b evenly distributed on the upper surface of the bottom plate 1302a, and a top plate 1302c parallel to the bottom plate 1302a arranged on the top of the vertical fins 1302b. 10 is connected to the top plate 1302c. When the external air temperature of the electromagnetic switch drops due to the weather, water vapor will condense on the radiator 1302 and the part of the copper braid 10 close to the radiator 1302 . Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com