A Damper

A technology of damping mechanism and damping oil, which is applied in building structure, door/window fittings, wing leaf parts, etc. It can solve the problems of limited oil tank area, increased weight of toilet cover, and limited installation space, etc., and achieves a simple and compact structure , prevent impact, increase the effect of damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

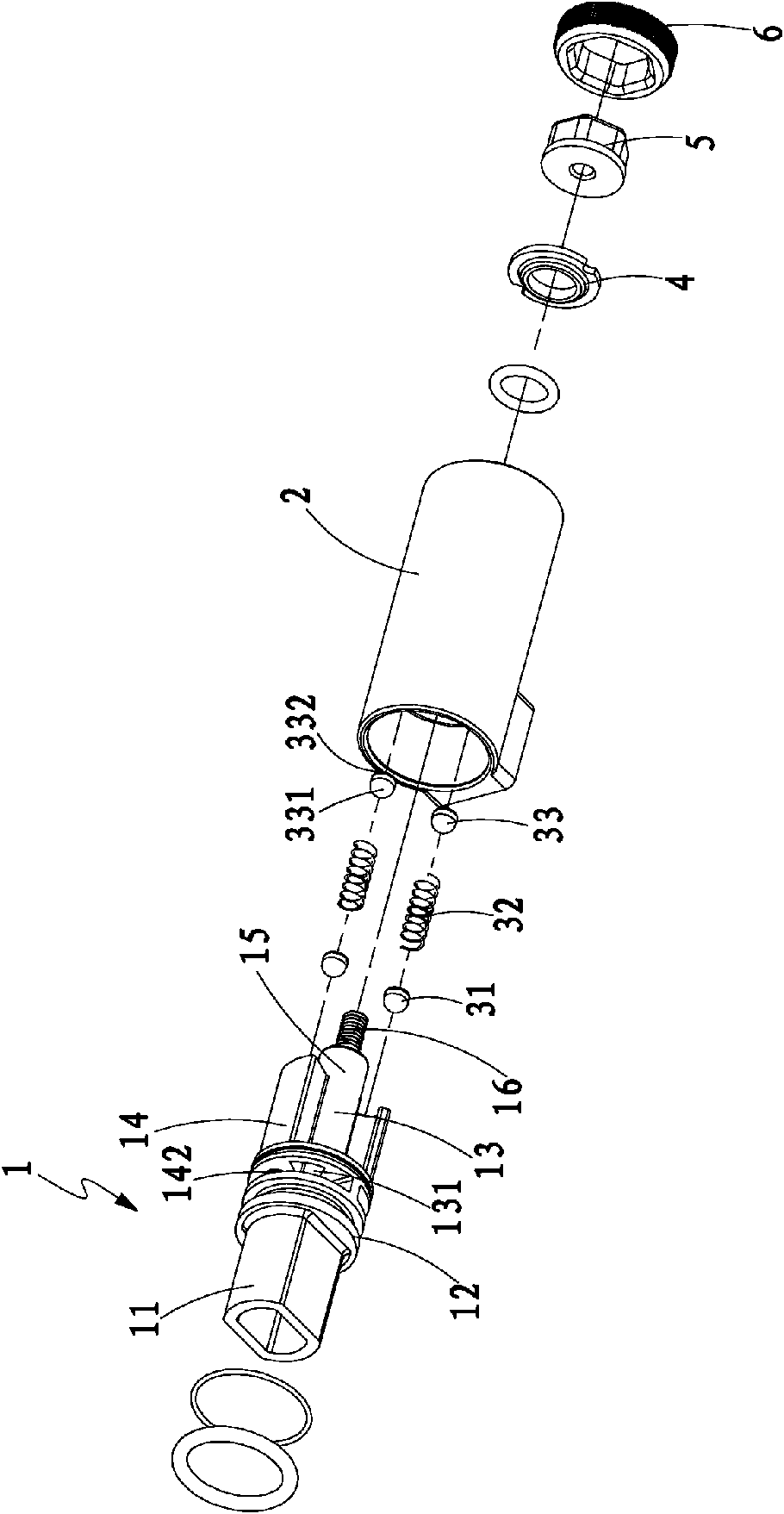

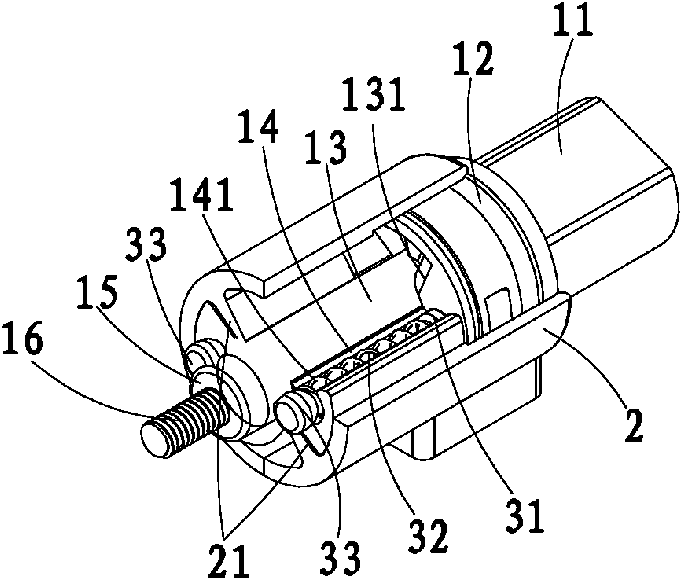

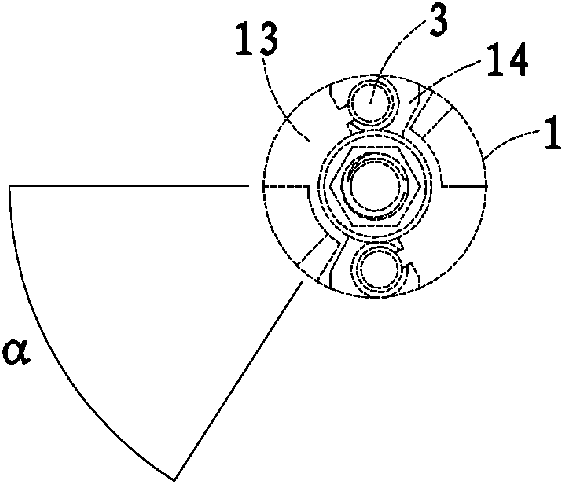

[0082] The present invention will be further described below in conjunction with accompanying drawing.

[0083] Such as Figure 1 to Figure 2-6 As shown, a damping mechanism disclosed by the present invention includes a rotating shaft 1, a shaft sleeve 2, a damping device 3, damping oil, a sealing ring 4, a nut 5 and a shaft sleeve fixing member 6; the sealing ring 4, the nut 5 and The shaft sleeve fixing part 6 forms a connecting part between the rotating shaft 1 and the shaft sleeve 2 . Here, the application to the toilet cover is taken as an example for illustration.

[0084] The rotating shaft 1 is assembled in the shaft sleeve 2, and the shaft 1 is provided with a special-shaped matching part 11 which is matched with the cover plate E, and a flange 12 is provided adjacent to the matching part to sleeve the sealing member and the shaft sleeve 2 for sealing fit. Adjacent to the flange 12, there are two symmetrical matching grooves 13 extending toward the front of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com