Heavy anti-corrosion paint made of epoxy resin and basalt scales

A technology of epoxy resin and basalt, applied in epoxy resin coatings, anti-corrosion coatings, polyamide coatings, etc., can solve the problems of poor resistance to medium permeability and wear resistance, complex construction conditions, short service life, etc., and achieve adhesion High strength, low curing residual stress, easy repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Component A:

[0012] 40 parts by weight of epoxy resin, 30 parts by weight of dibutyl phthalate, 29 parts by weight of dispersant, 38 parts by weight of defoamer, 32 parts by weight of leveling agent, 19 parts by weight of pigment zinc phosphate, 50 parts by weight of basalt flakes ;

[0013] B component:

[0014] 28 parts by weight of polyamide, and 32 parts by weight of solvent.

[0015] Wherein the solvent is a mixed solvent, composed of n-butanol:xylene volume ratio=17:7.

[0016] When in use, mix components A and B at a ratio of 5:1.

Embodiment 2

[0018] Component A:

[0019] 25 parts by weight of epoxy resin, 35 parts by weight of dibutyl phthalate, 20 parts by weight of dispersant, 35 parts by weight of defoamer, 23 parts by weight of leveling agent, 22 parts by weight of pigment zinc phosphate, 65 parts by weight of basalt flakes ;

[0020] B component:

[0021] 30 parts by weight of polyamide, 35 parts by weight of solvent.

[0022] Wherein the solvent is a mixed solvent, composed of n-butanol:xylene volume ratio=18:7.

[0023] When in use, mix components A and B at a ratio of 6:1.

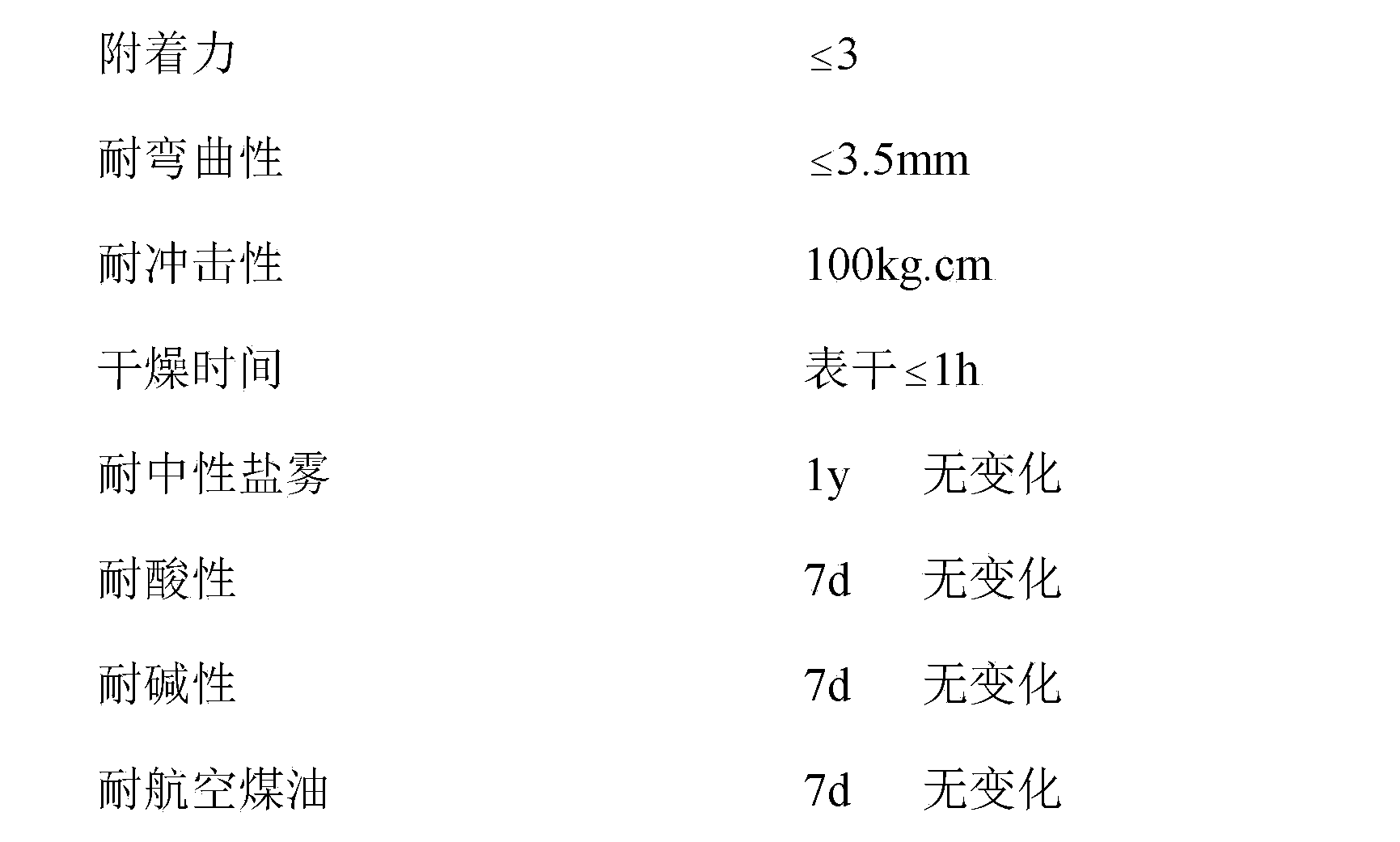

[0024] Detect the performance parameter of above each embodiment by routine method, result is as follows:

[0025]

[0026] The present invention uses basalt scales as fillers, utilizes its labyrinth effect to effectively block the penetration of corrosive media, and its penetration rate is reduced by 8-9 times. Small coefficient, low curing residual stress, wear resistance, simple construction, easy repair and many other advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com