A method for preparation of enantioselective composite membrane

An enantioselective, composite membrane technology, applied in the field of preparation of enantioselective composite nanofiltration membranes, can solve the problem of selectivity decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

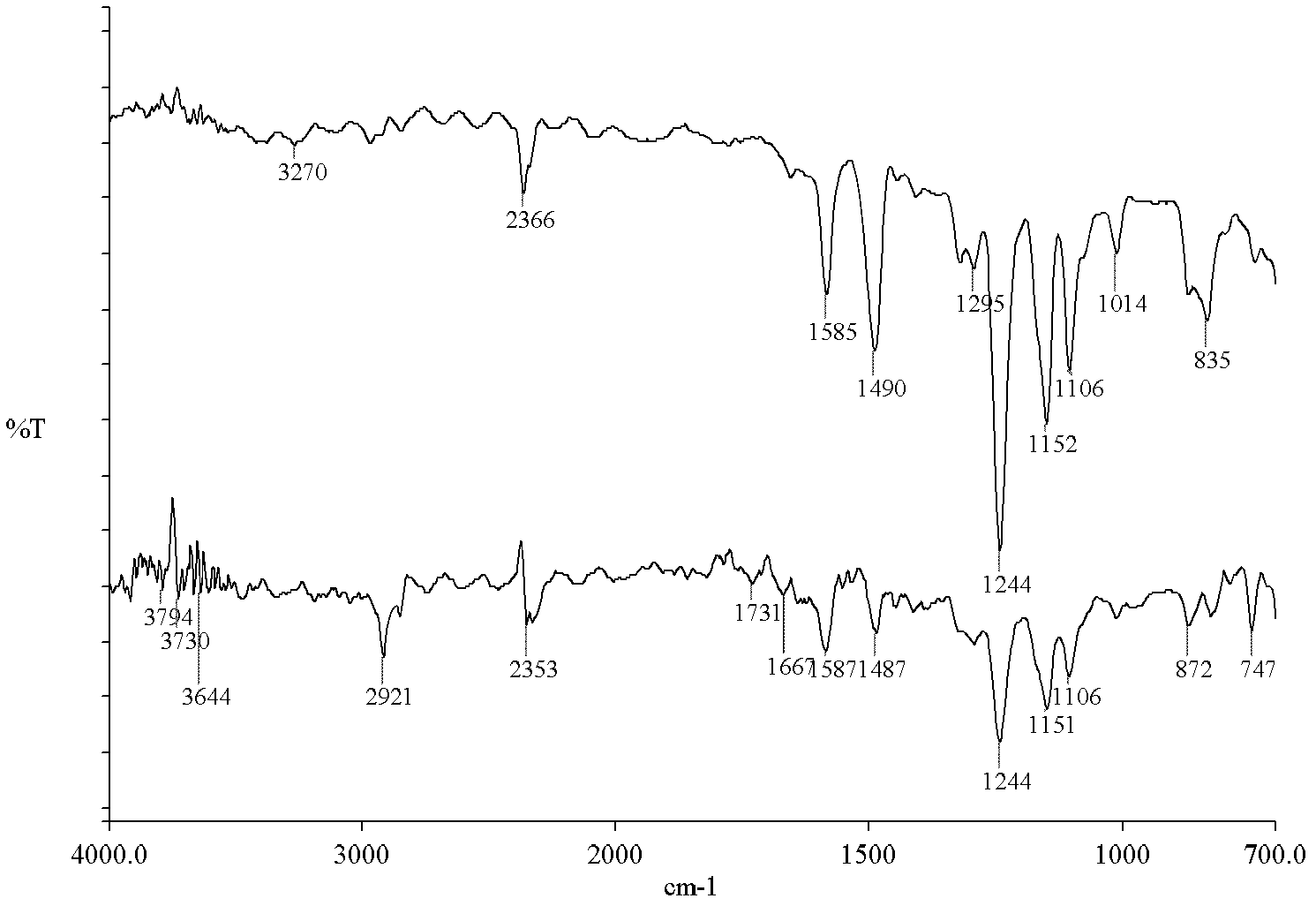

Image

Examples

Embodiment 1

[0053] The preparation method of the enantioselective composite membrane comprises: immersing the polysulfone UF membrane in the aqueous solution of 1% arginine and piperazine (Piprazine) (50:50) for 3 minutes, and keeping the solution by adding 1N NaOH pH 12, excess solution was drained for 15 min, membrane was then immersed in 0.5% trimesoyl chloride in hexane for 2 min, excess solution was drained for 2 min, and membrane was air dried for 4 Hour. The films were heat cured at a temperature of 90°C for 5 minutes, cooled to a temperature of 25°C, air dried for 2 hours, and soaked in deionized water for up to 24 hours. The separation and enantioselectivity of the membranes for arginine were tested under standard conditions: 0.1% aqueous solution of racemic arginine was used as feed at a flow rate of 500 ml per minute at 552 KPa. The membrane exhibited a permeation rate of 636 l / m 2 / day, the arginine rejection (rejection) was 75%, and the enantioselectivity to d-arginine was ...

Embodiment 2

[0055]The preparation method of the enantioselective composite membrane comprises: immersing the polysulfone UF membrane in the aqueous solution of 1% arginine and piperazine (50:50) for 3 minutes, and maintaining the pH of the aqueous solution at 12 by adding 1N NaOH , the excess solution was drained over 15 minutes, the membrane was then immersed in 1% trimesoyl chloride in hexane for 2 minutes, the excess solution was drained over 5 minutes, and the membrane was air dried for 4 hours. The films were heat cured at a temperature of 90°C for 5 minutes, cooled to a temperature of 25°C, air dried for 2 hours, and soaked in deionized water for up to 24 hours. The separation and enantioselectivity of the membrane for arginine were tested under standard conditions: 0.1% aqueous solution of racemic arginine was used as feed, the flow rate was 500 ml per minute at 552 KPa. After 6 hours the membrane exhibited a permeation rate of 734 l / m 2 / day, the arginine rejection rate was 66%, ...

Embodiment 3

[0057] The preparation method of the enantioselective composite membrane comprises: immersing the polysulfone UF membrane in 1% piperazine aqueous solution for 3 minutes, maintaining the pH of the aqueous solution at 12 by adding 1N NaOH, draining off the excess solution for 15 minutes, The membrane was then dipped in a 0.5% solution of trimesoyl chloride in hexane for 2 minutes, the excess solution was drained over 5 minutes, and the membrane was air dried for 4 hours. The films were heat cured at a temperature of 90°C for 5 minutes, cooled to a temperature of 25°C, air dried for 2 hours, and soaked in deionized water for up to 24 hours. The membrane was tested under standard conditions: 0.1% aqueous solution of racemic arginine was used as feed, the flow rate was 500 ml per minute at 552 KPa. The membrane exhibited a permeation rate of 1125 l / m 2 / day, the arginine retention rate was 60%. The membrane showed no enantioselectivity for d-arginine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com