Locking and self-discharging mechanism for wire reels

A locking mechanism and winding reel technology, which is applied in the field of winding machinery and equipment, can solve the problems of high concentricity requirements of mechanical processing equipment, inability to realize automation of winding equipment, and strict requirements for installation accuracy, so as to achieve social benefits and economic benefits. Benefit and win-win, reduce the labor intensity of workers, and have the effect of large unloading space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with specific embodiments.

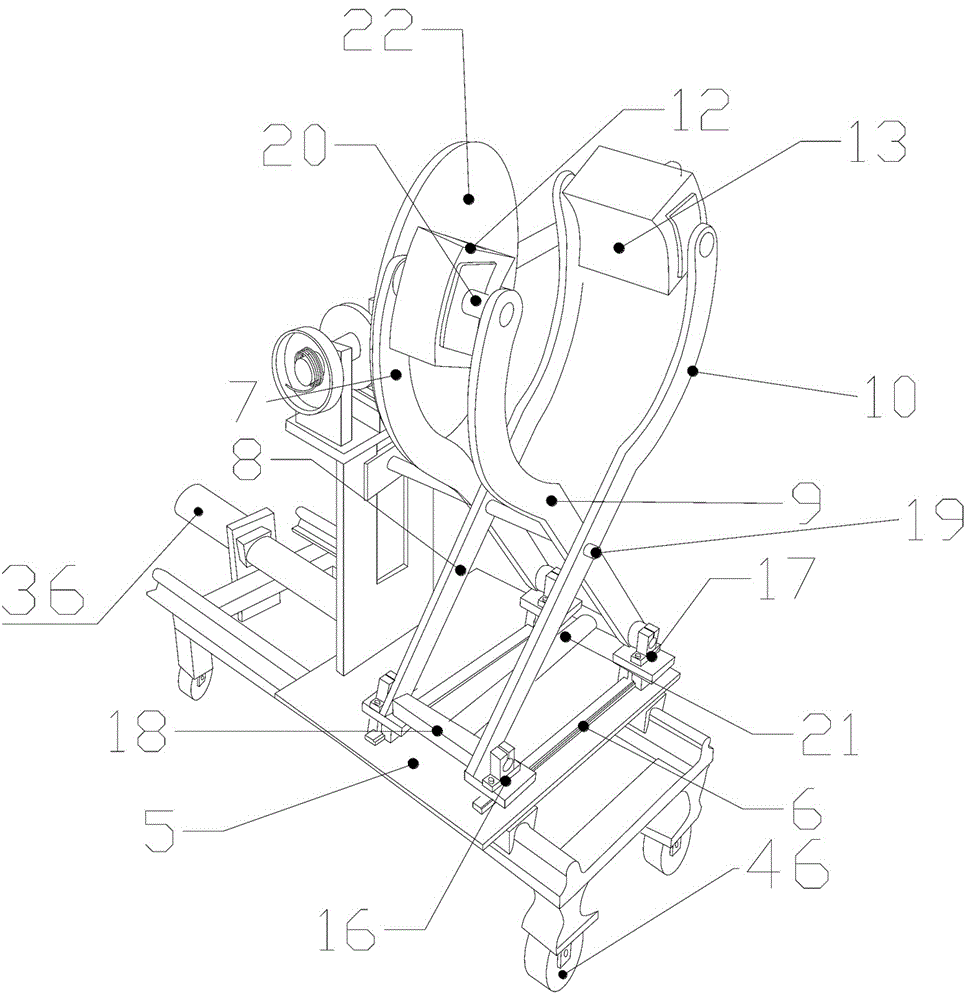

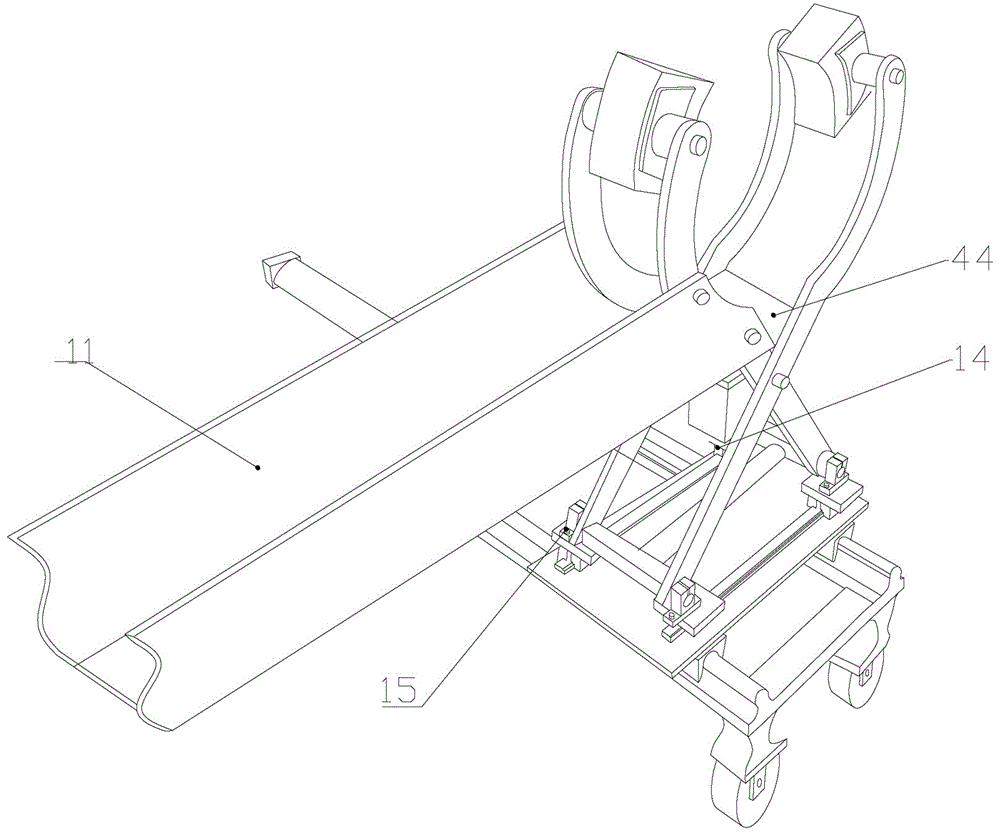

[0036] like figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10, a winding reel locking self-unloading mechanism, including a base, including a locking mechanism and an unloading mechanism, and the locking mechanism includes a box body 1, fixed disk 2 and driven disk 22, the fixed disk 2 is arranged movable on the box body 1, and the center of the fixed disk 2 is vertically provided with a main shaft 3 for wrapping the winding disk 4, and the The fixed disk 2 is movably plugged with the driven disk 22 through the main shaft 3, and the driven disk 22 is arranged on the base through a moving mechanism.

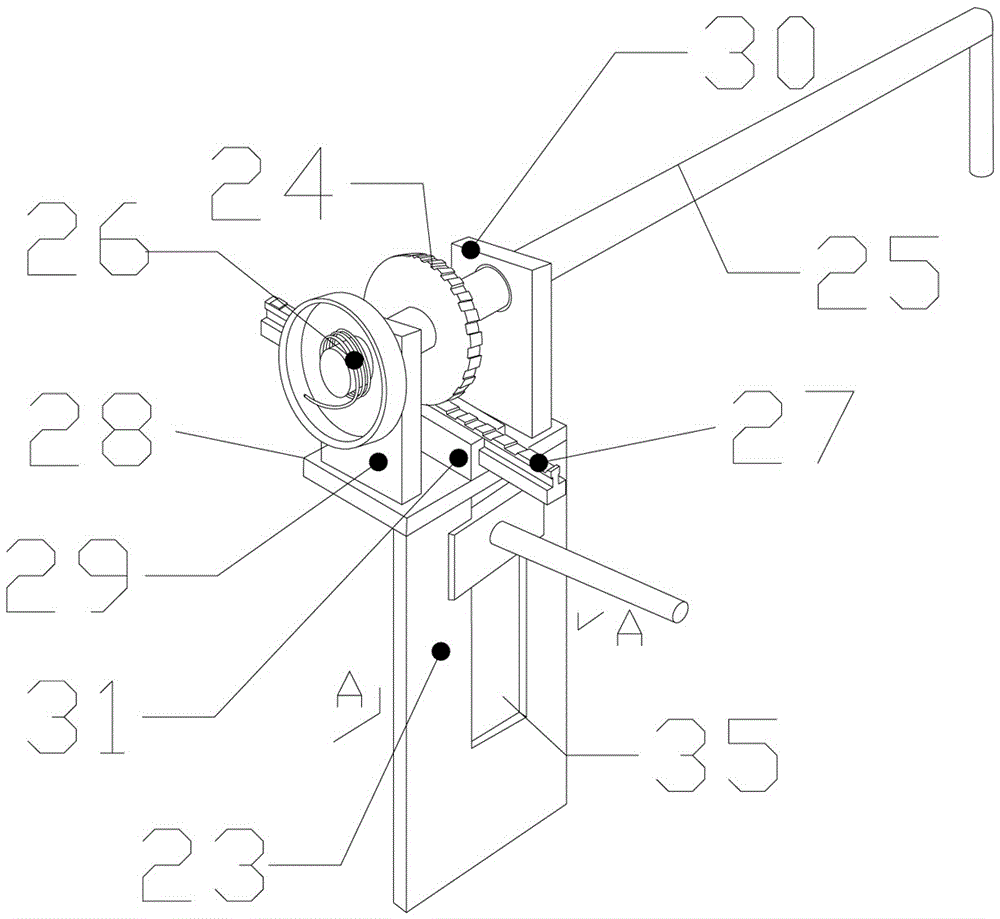

[0037]Described moving mechanism comprises a vertical support plate 23, lateral support plate 28, driving gear 24, handle 25, back-moving spring 26, tooth bar 27, and described vertical support plate 23 bottoms are vertically fixed on support arm one 7 1. On the underframe 5 on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com