Method and special device for performing fusion welding on electrode lead plate of energy-saving environment-friendly type lead-acid battery

A lead-acid battery, energy-saving and environment-friendly technology, which is applied in the field of lead-acid battery manufacturing, can solve the problems of liquid lead detonation in lead pools, large energy waste, and environmental pollution, and achieve the effects of reducing contact, improving work efficiency, and accurate quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

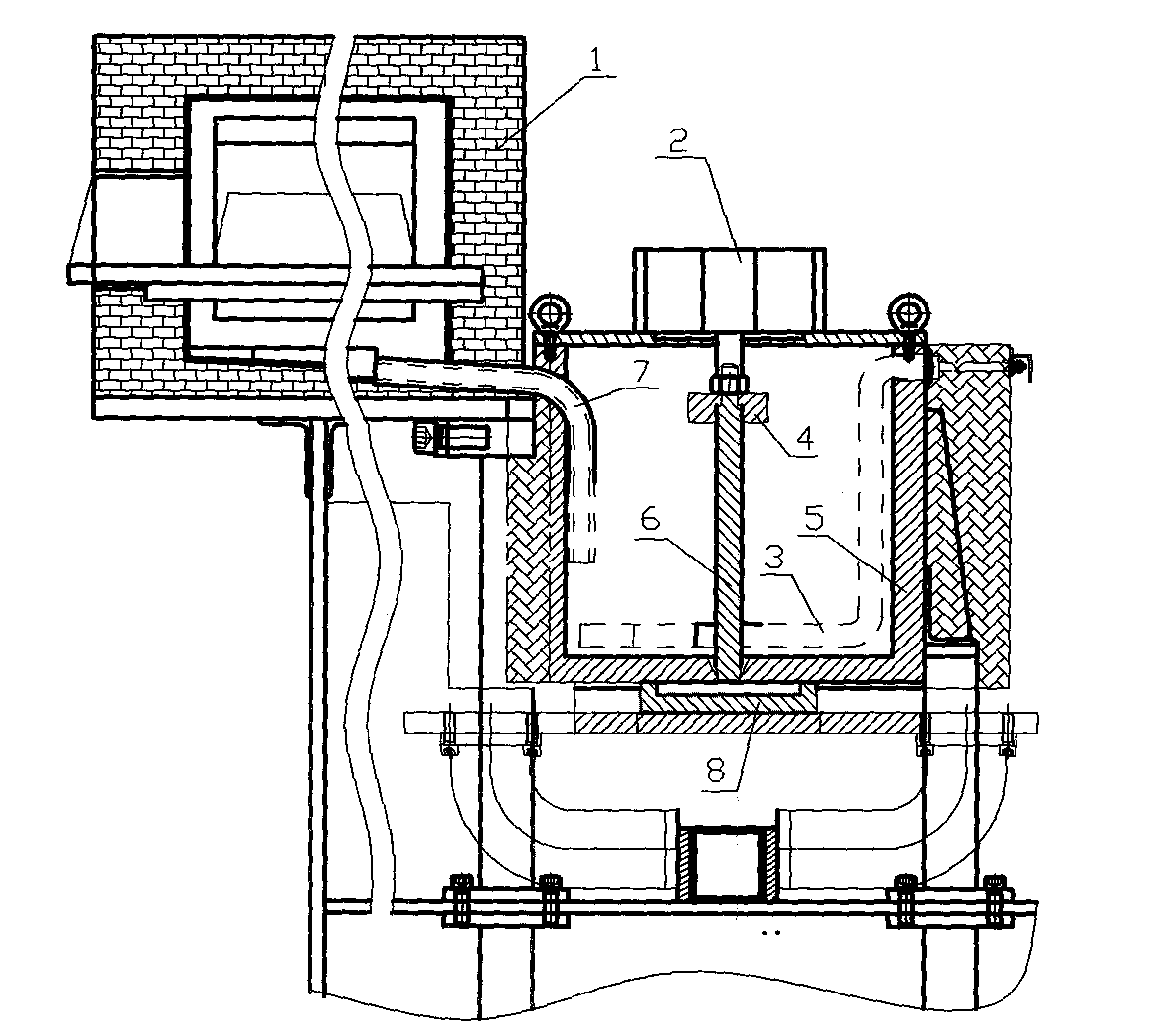

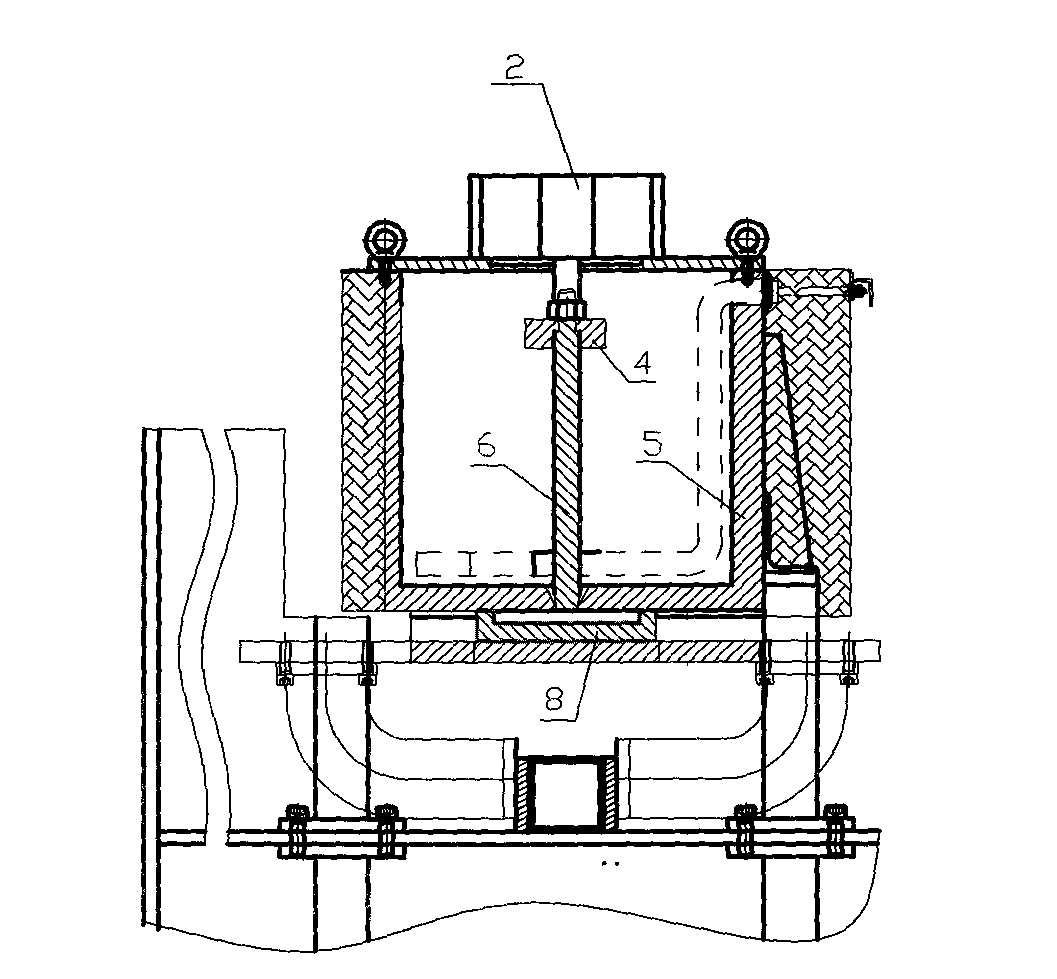

[0026] The method scheme of the present invention is: comprising heating and melting solid lead, heat preservation of liquid lead, injecting lead into a rectangular groove of a melting template, welding, cooling, and tooling box being separated from the lead plate, and is characterized in that the specific steps are:

[0027] ①The solid lead is heated and melted and injected into a lead storage tank with heat preservation device, or a lead injection tank integrating lead and heat preservation is installed to heat and melt the solid lead, and the melting plate is preheated to 100°C-320°C; The electromagnetic induction coil installed above the upper surface of the melting plate of the front station of the lead injection station is energized and heated. When the enthalpy value of the melting plate itself has reached the 100°C-320°C required by the preheating interval process during the working process, the preheating is stopped. hot.

[0028] ②The melting plate is moved to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com