Copper-zirconium alloy for electronic component and preparation method of copper-zirconium alloy

A technology of electronic components and copper-zirconium alloys, which is applied in the field of copper-zirconium alloys for electronic components and its preparation, can solve the problems of high cost of Ag elements, high cost of industrialization, unfavorable promotion, etc., achieve low cost and improve comprehensive performance , the effect of reducing oxidation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

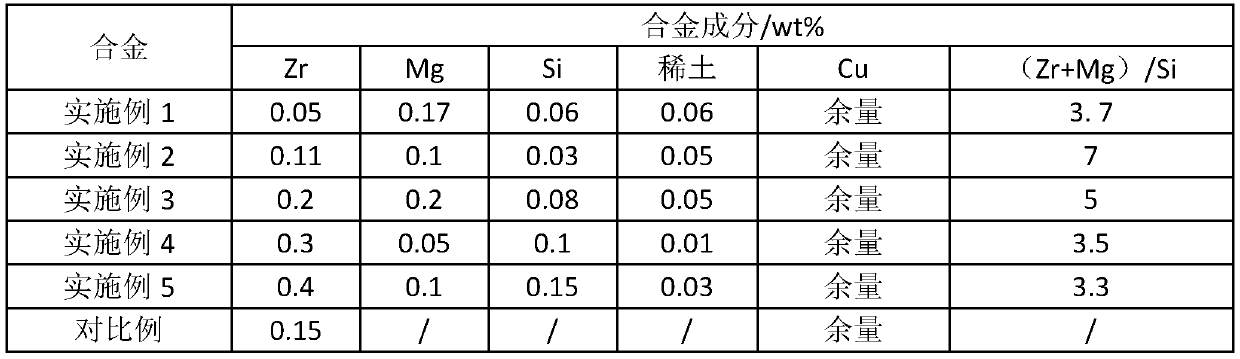

Examples

Embodiment 1

[0029] (1) Melting: Put copper into an induction melting furnace, add charcoal and flake graphite, melt under an argon protective atmosphere, and perform degassing treatment to obtain a copper melt;

[0030] (2) Alloying: adding the master alloys Cu-10wt%Mg, Cu-15wt%Si, Cu-10wt%La, Cu-15wt%Zr into the furnace in turn, keeping the temperature until completely melted to obtain a copper alloy melt;

[0031] (3) Casting: casting the copper alloy melt obtained in step (2) at a casting temperature of 1180° C. to obtain a slab of 200×600 mm in size, the components are Zr 0.05wt%, Mg 0.17wt%, Si 0.06wt%, La 0.06 wt%, the balance is Cu and unavoidable impurities;

[0032] (4) Hot rolling: hot rolling and online quenching are carried out to the copper alloy cast slab obtained in step (3), the hot rolling heating temperature is 880°C, the heat preservation is 4h, the final rolling temperature is 700°C, and the thickness of the hot rolled slab is 16mm;

[0033] (5) Rough rolling: carry o...

Embodiment 2

[0039] (1) Melting: Put copper into an induction melting furnace, add charcoal and flake graphite, melt it under a nitrogen protective atmosphere, and perform degassing treatment to obtain a copper melt;

[0040] (2) Alloying: adding the master alloys Cu-10wt%Mg, Cu-15wt%Si, Cu-10wt%Ce, Cu-15wt%Zr into the furnace in turn, keeping the temperature until completely melted to obtain a copper alloy melt;

[0041] (3) Casting: casting the copper alloy melt obtained in step (2) at a casting temperature of 1200° C. to obtain a slab of 200×600 mm in size, the components are Zr 0.11wt%, Mg 0.1wt%, Si 0.03wt%, Ce 0.05 wt%, the balance is Cu and unavoidable impurities;

[0042] (4) Hot rolling: hot rolling and online quenching are carried out to the copper alloy cast slab obtained in step (3), the hot rolling heating temperature is 900°C, the heat preservation is 4h, the final rolling temperature is 720°C, and the thickness of the hot rolled slab is 16mm;

[0043] (5) Rough rolling: car...

Embodiment 3

[0049] (1) Melting: Put copper into an induction melting furnace, add charcoal and flake graphite, melt under an argon protective atmosphere, and perform degassing treatment to obtain a copper melt;

[0050] (2) Alloying: Add the master alloys Cu-10wt%Mg, Cu-15wt%Si, Cu-10wt%Y, Cu-15wt%Zr into the furnace in sequence, and keep warm until completely melted to obtain a copper alloy melt;

[0051] (3) Casting: casting the copper alloy melt obtained in step (2) at a casting temperature of 1250° C. to obtain a slab of 200×600 mm in size, with components of Zr 0.2wt%, Mg 0.2wt%, Si 0.08wt%, Y 0.05 wt%, the balance is Cu and unavoidable impurities;

[0052] (4) Hot rolling: hot rolling and online quenching are carried out to the copper alloy cast slab obtained in step (3), the hot rolling heating temperature is 920°C, the heat preservation is 4h, the final rolling temperature is 700°C, and the thickness of the hot rolled slab is 16mm;

[0053] (5) Rough rolling: carry out cold rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com