Low-temperature grain storage method for low-temperature barn

A granary, low-temperature technology, applied in the field of low-temperature grain storage, can solve the problems of low degree of automation, unfavorable grain storage, and increase energy consumption, and achieve the effect of high degree of intelligence, improved refrigeration effect, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

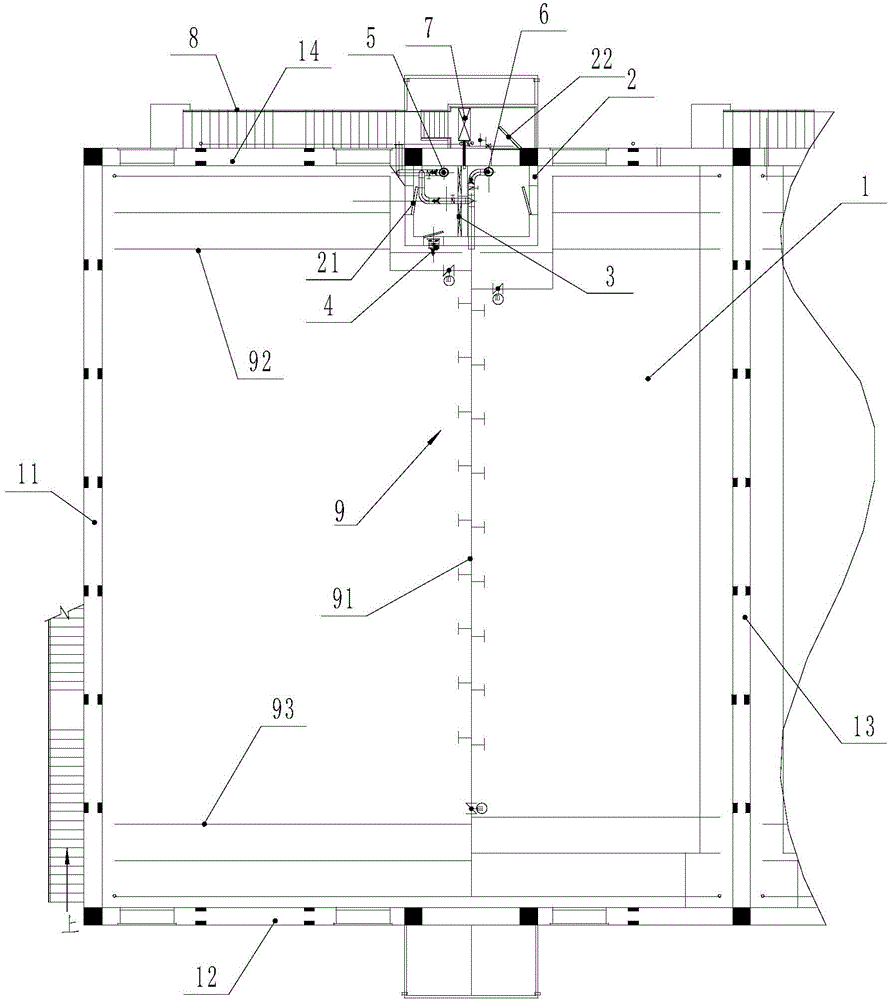

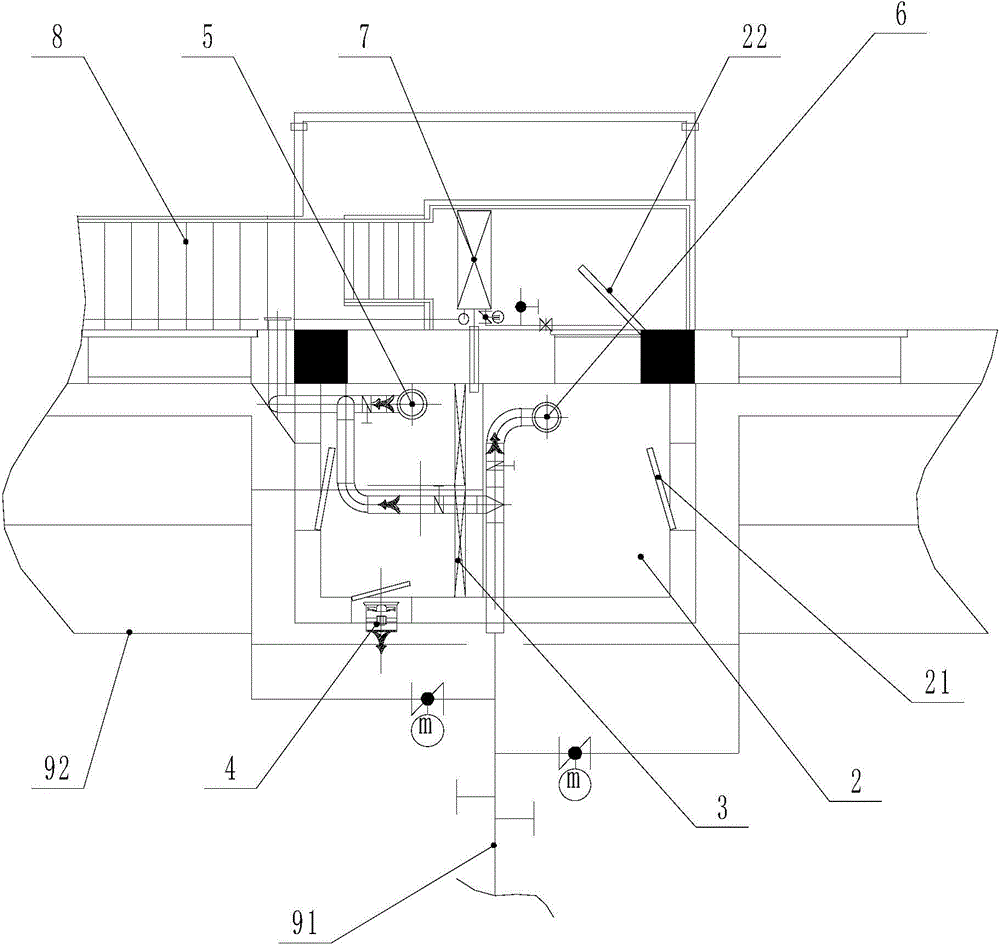

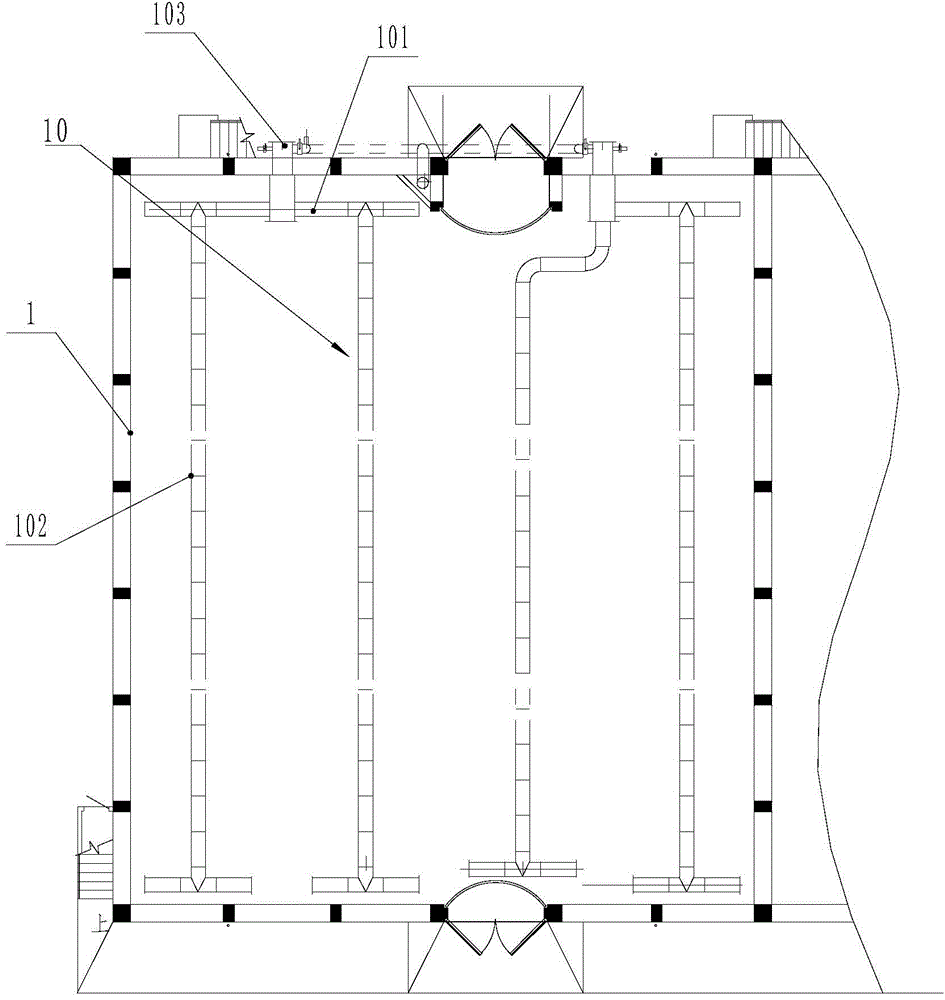

[0021] Such as Figure 1 to Figure 4 As shown, a low-temperature granary intelligent refrigeration system includes a granary 1, and generally speaking, several granaries 1 are arranged side by side to form a granary, and the construction of the granary is preferably close to the river, which can prevent fires and facilitate transportation . The granary 1 is generally surrounded by the second horizontal wall 13, the first horizontal wall 11, the vertical wall 12 and the eaves wall 14. A refrigeration room 2 is suspended in the granary 1, and the refrigeration room 2 is arranged in the granary 1. The eaves wall 14 is located in the middle of the granary 1, and the refrigeration room 2 is provided with a ventilation window 21, which is used to communicate with the space above the grain pile in the granary 1, and the number of the ventilation windows 21 is Two and located on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com