Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

A technology of oriented silicon steel and equiaxed crystal ratio, applied in the field of continuous casting of steelmaking slabs, can solve the problems of inability to produce high-grade non-oriented silicon steel, small space of continuous casting machine, and inability to install electromagnetic stirring device, etc., to achieve the elimination of surface Effect of corrugation defects, improvement of internal quality and surface quality, improvement of thermodynamic and kinetic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

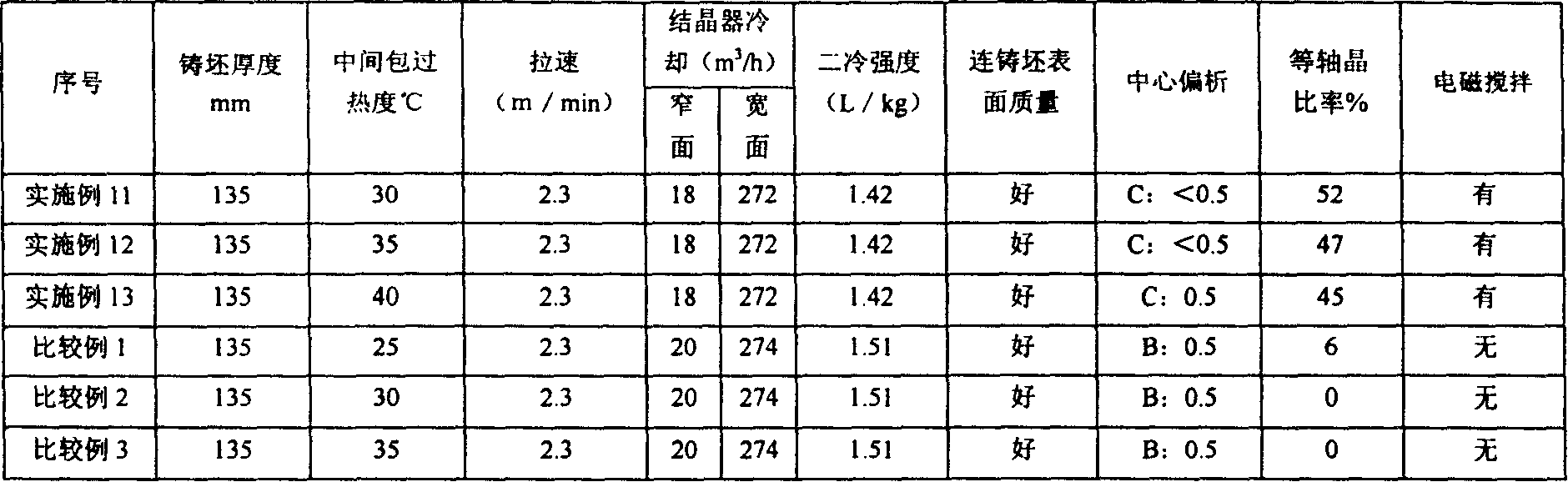

[0014] Converter smelting, RH-TB vacuum treatment to obtain C: 0.003%, Si: 2.0%, Mn: 0.25%, P: 0.08%, S: 0.005%, A1: 0.25%, N: 0.0035%, O: 0.012%, Ti , V, Nb, Zr, Gr, Cu and other trace alloys are all 3 / h, crystallizer width 272m 3 / h; Two-hole submerged nozzle, nozzle angle 15°. Compared with the proportion of equiaxed grains of continuous casting slab produced without electromagnetic stirring, see Table 1.

[0015] Table 1 Effect of electromagnetic stirring and continuous casting process system on the internal quality of 135mm thick slab

[0016]

Embodiment 2

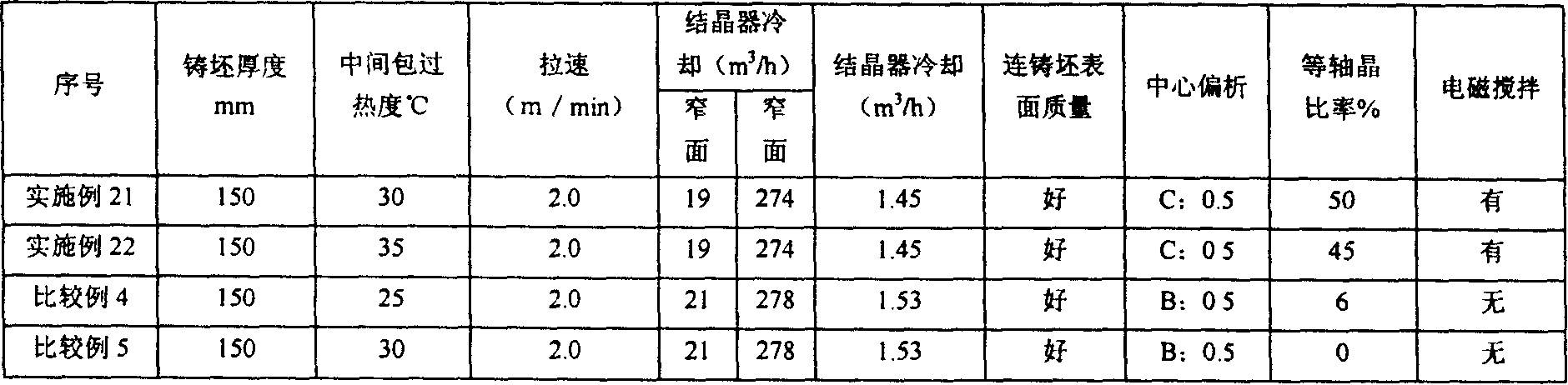

[0018] Converter smelting, RH-TB vacuum treatment to obtain C: 0.0040%, Si: 2.0%, Mn: 0.3%, P: 0.08%, S: 0.004%, Al: 0.27%, N: 0.0040%, O: 0.012%, Ti , V, Nb, Zr, Gr, Cu and other trace alloys are all less than 0.005%, and the rest is Fe. It is continuously cast into slabs and hot rolled at a casting speed of 2.0m / min, and then pickled and cold rolled into 0.5mm thick slabs. Cold-rolled sheet, finished silicon steel sheet after final annealing. Mold cooling system of continuous casting machine: the narrow side of the mold is 19m 3 / h, crystallizer width 274m 3 / h; Two-hole submerged nozzle, nozzle angle 15°. Compared with the proportion of equiaxed grains of continuous casting slab produced without electromagnetic stirring, see Table 2.

[0019] Table 2 Effect of electromagnetic stirring and continuous casting process system on the internal quality of 150mm thick slab

[0020]

Embodiment 3

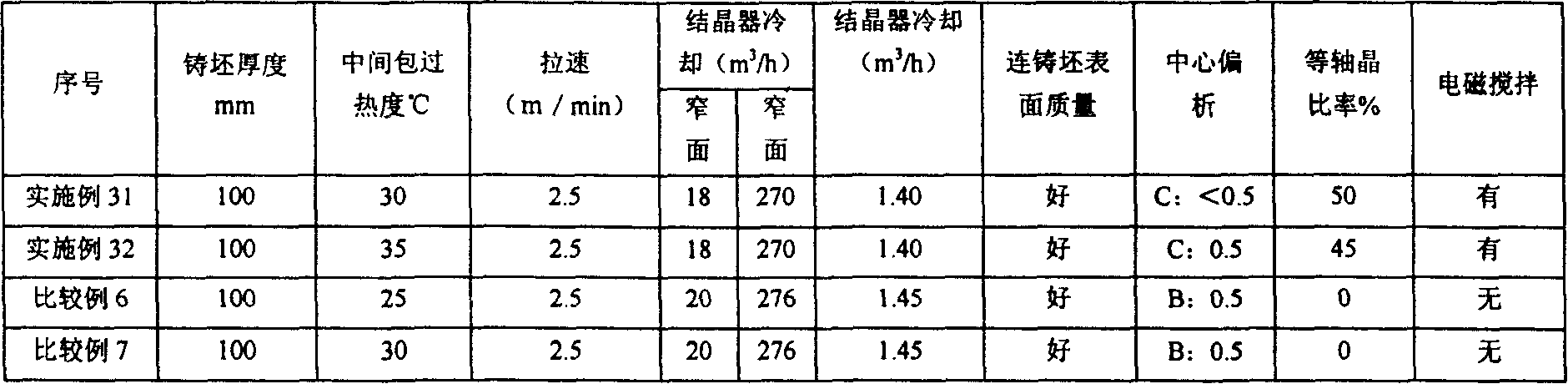

[0022] Converter smelting, RH-TB vacuum treatment to obtain C: 0.003%, Si: 2.0%, Mn: 0.25%, P: 0.08%, S: 0.004%, Al: 0.28%, N: 0.0035%, O: 0.011%, Ti , V, Nb, Zr, Gr, Cu and other trace alloys are all less than 0.005%, and the rest is Fe. It is continuously cast into slabs and hot rolled at a casting speed of 2.5m / min, and then pickled and cold rolled into 0.5mm thick slabs. Cold-rolled sheet, finished silicon steel sheet after final annealing. Continuous casting machine crystallizer cooling system: the narrow side of the crystallizer is 18m 3 / h, crystallizer width 270m 3 / h; Two-hole submerged nozzle, nozzle angle 15°. Compared with the equiaxed grain ratio of continuous casting slab produced without electromagnetic stirring, see Table 3.

[0023] Table 3 Effect of electromagnetic stirring and continuous casting process system on the internal quality of 100mm thick slab

[0024]

[0025]Tables 1 to 3 all adopt low magnification and dendrite corrosion inspection. The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com