Casting forming system with turnover directional cooling function and using method thereof

A technology of directional cooling and casting molding, which is applied in the direction of casting equipment, mold handling equipment, manufacturing tools, etc., to achieve the effects of improving efficiency, reasonable solidification temperature field, and increasing cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

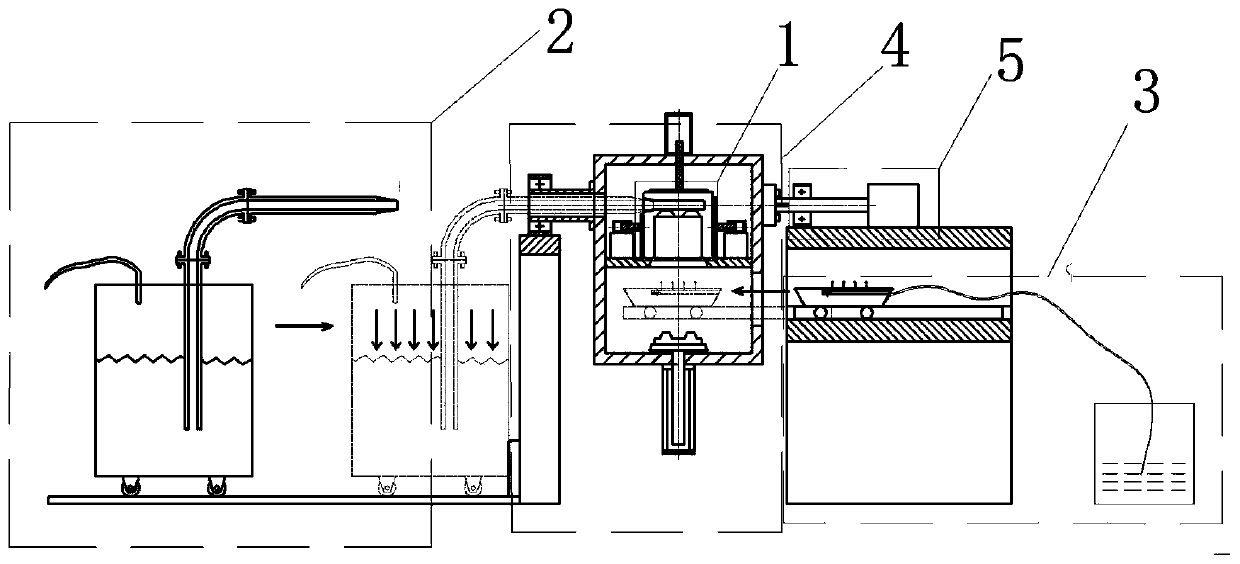

[0058] This embodiment relates to a casting molding system with flipping and directional cooling and its application method; refer to Figure 1-Figure 6 , the foundry molding system with flipping and directional cooling includes:

[0059] 1) Sand mold 1, which constitutes a part of composite mold 110;

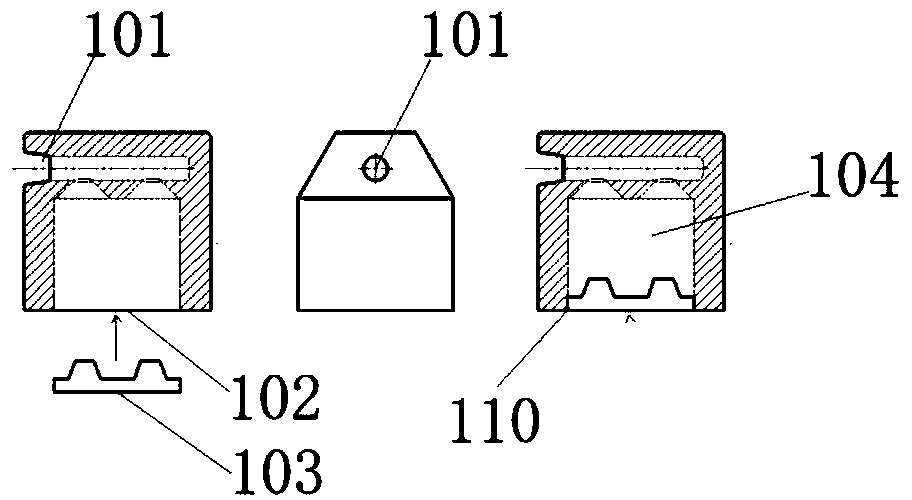

[0060] Such as figure 2 , the side wall of the sand mold 1 is provided with a sprue 101; the bottom of the sand mold 1 is provided with a sand mold bottom opening 102, which can be combined with a chilled mold 103 with a molding surface, thereby defining a mold cavity 104;

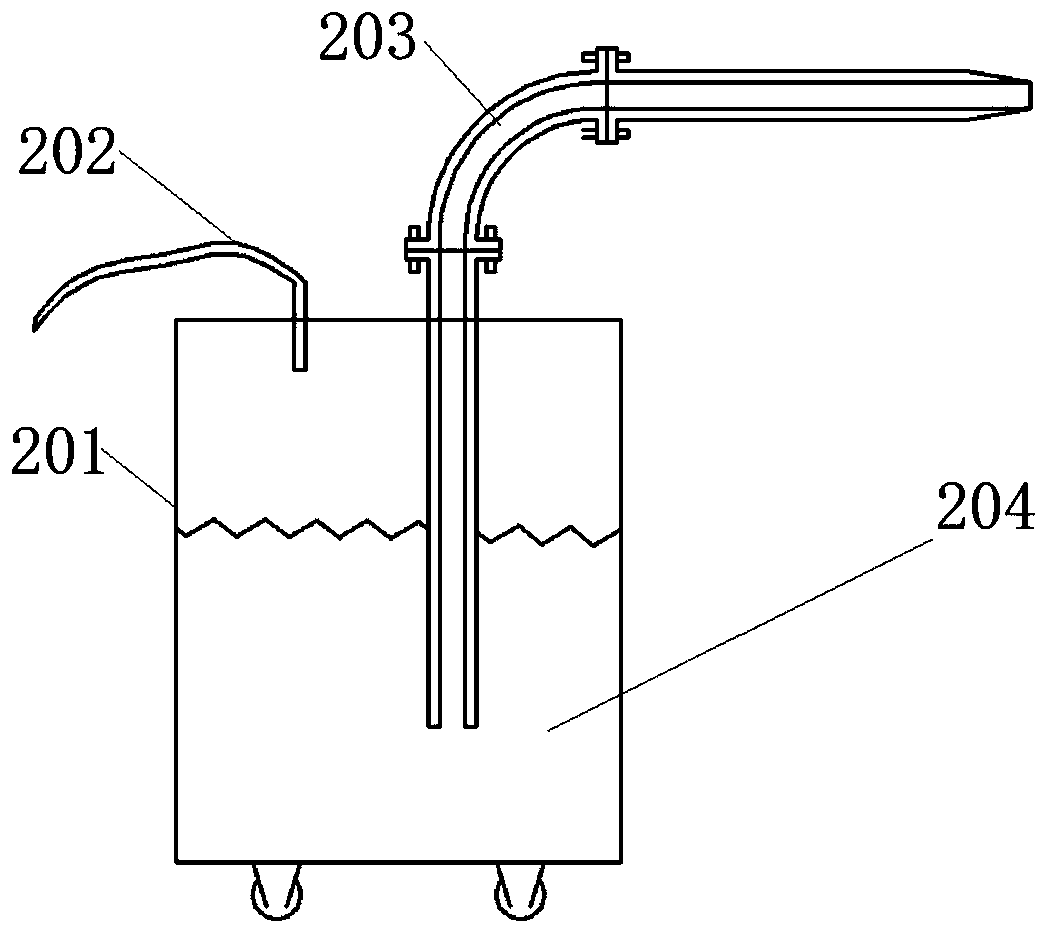

[0061] 2) Liquid metal delivery system 2, such as image 3 The molten metal conveying system 2 includes a molten metal melting and holding furnace 201, a low-pressure casting liquid surface pressurization device 202, and a molten metal conveying pipeline 203; the molten metal 204 to be poured is contained in the molten metal melting and holding furnace 201; The above-mentioned molten metal melting and h...

Embodiment 2

[0080] This embodiment relates to a casting molding system with flipping and directional cooling and its application method; refer to figure 2 , 4 , Figure 7-Figure 10 , the foundry molding system with flipping and directional cooling includes:

[0081] 1) Sand mold 1, which forms part of a complete mold 110;

[0082] Such as figure 2 , the side wall of the sand mold 1 is provided with a sprue 101; the bottom of the sand mold 1 is provided with a sand mold bottom opening 102, which can be combined with a chilled mold 103 with a molding surface, thereby defining a mold cavity 104;

[0083] 2) Liquid metal delivery system 2, such as Figure 8 , the molten metal delivery system 2 includes a molten metal melting and holding furnace 201, an electromagnetic pump 205, and a molten metal delivery pipeline 203; the molten metal 204 to be poured is contained in the molten metal melting and holding furnace 201; the molten metal is melted and kept warm The furnace 201 can reciproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com