Method capable of adjusting heating uniformity of coke oven in length direction from lower portion and oven body structure

A furnace body structure and uniformity technology, which is applied in the heating of coke ovens, combustible gas heating coke ovens, coke ovens, etc., can solve the problems of unrealization and difficulty in adjusting the uniformity of heating in the long direction, and achieve reasonable structure and fire path. The temperature is uniform and reasonable, avoiding the effect of local high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

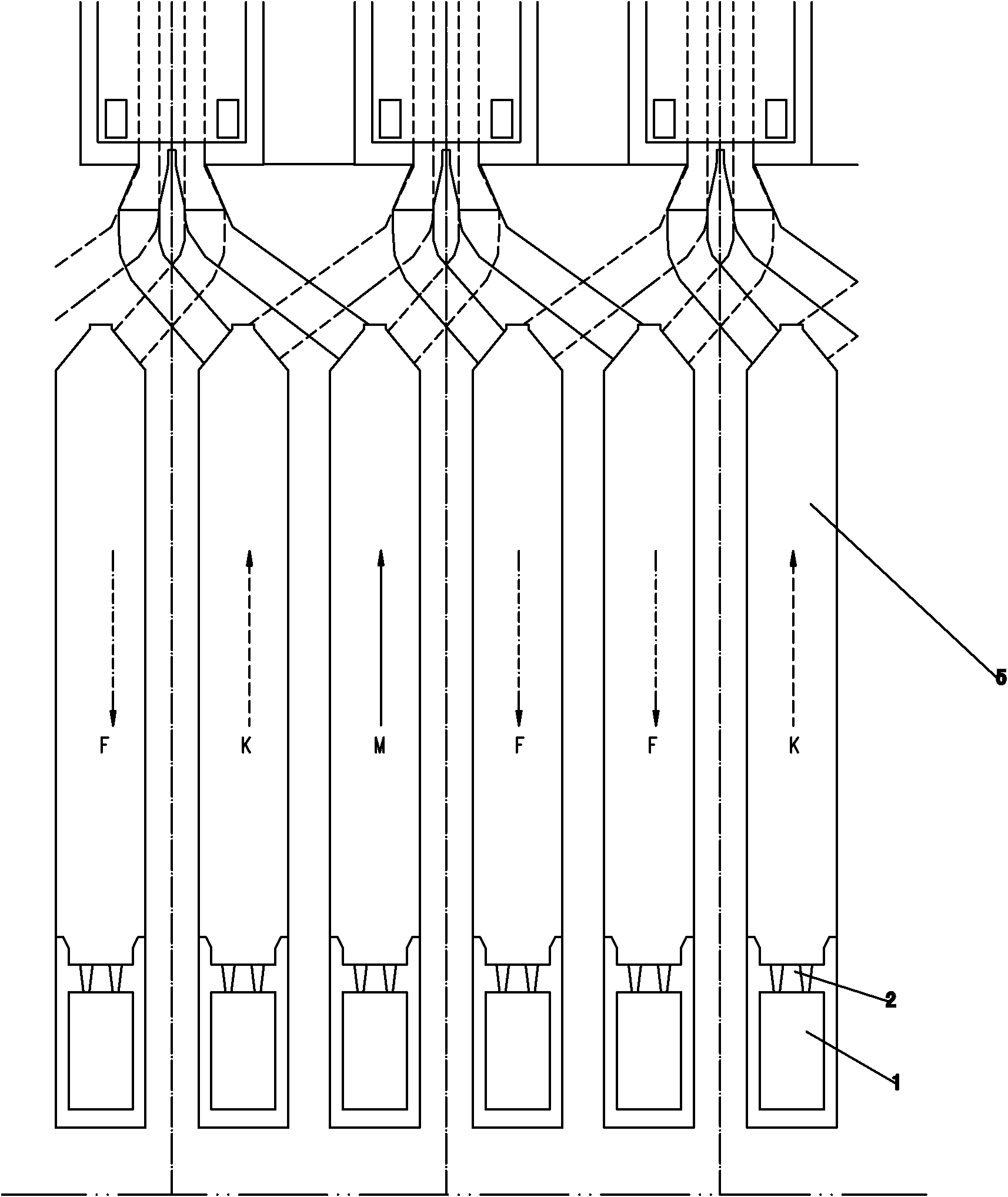

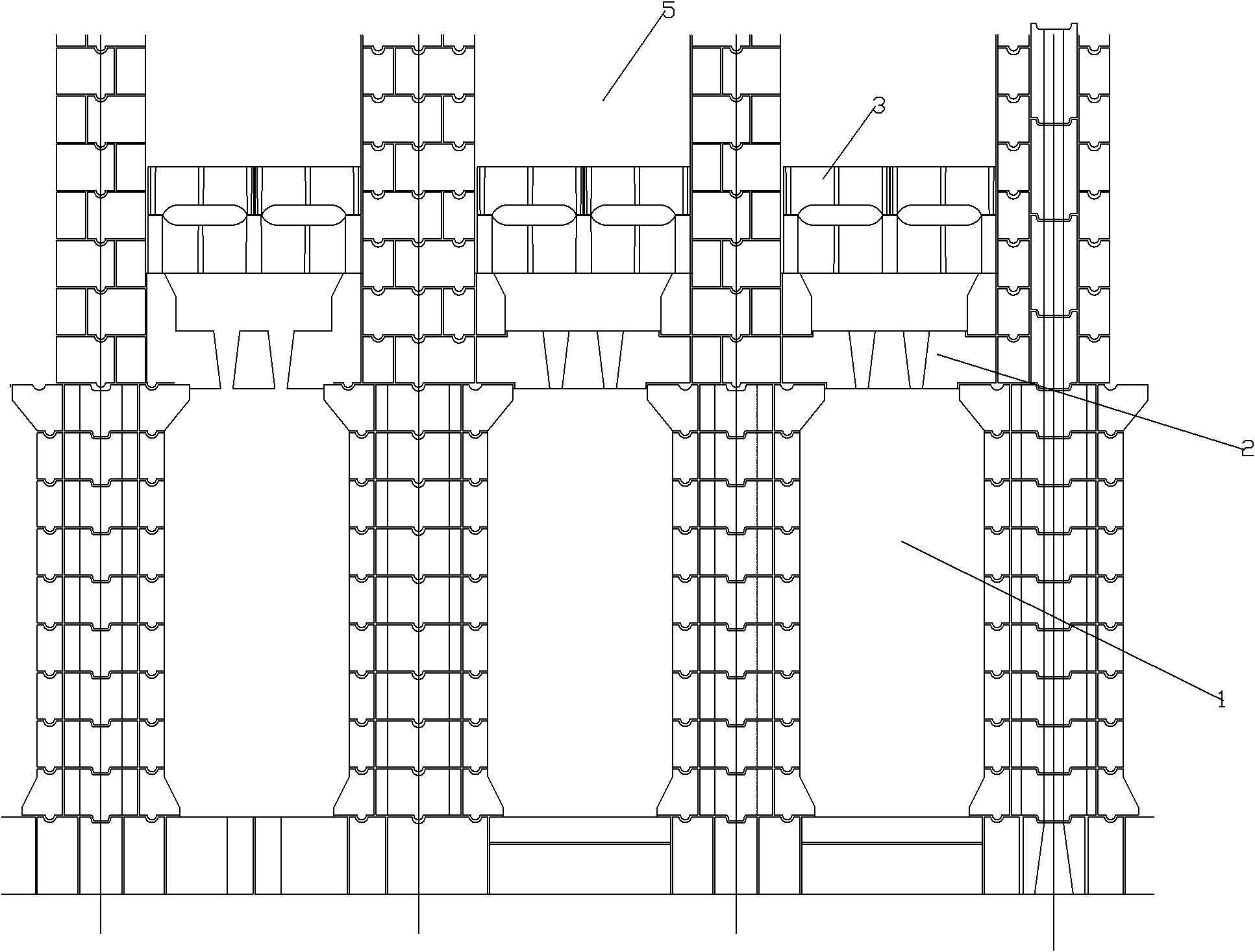

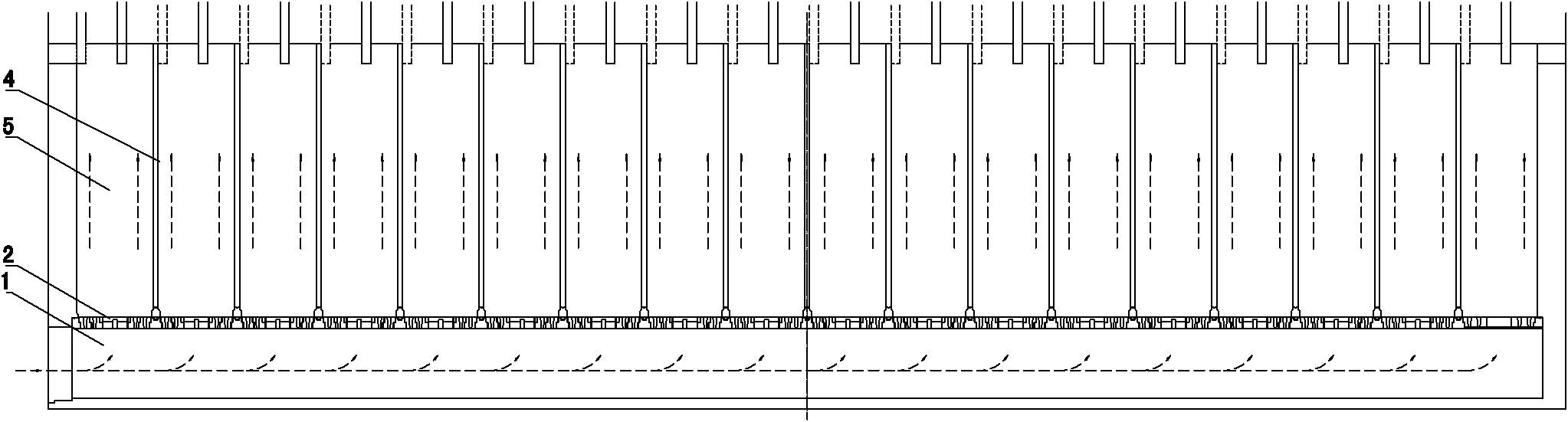

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] See Figure 1-Figure 5 , a coke oven body structure, including a small flue 1, the small flue 1 and the main wall and single wall of the regenerator 5 are all integral structures, and the bottom of the regenerator 5 on the top of the small flue 1 can be set Regulating gas passes through the grate brick 2 of cross-sectional area. The size adjustment of the grate brick hole 9 is realized by adding and subtracting the adjusting brick 10 to the grate brick hole at the basement, and this structure can achieve the purpose of adjusting the lengthwise distribution of the regenerator. The regenerator 5 is provided with a checker brick 3 regenerator.

[0026] See image 3 , each regenerator is divided into several cells along the lengthwise direction, and each regenerator is divided into multiple gas channels, and the gas volume entering each gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com