Solar cell and assembly and manufacturing method thereof

A technology for solar cells and batteries, applied in the field of solar cells, can solve the problems of hot spots of battery current, unsightly appearance, broken grids, etc., and achieve the effects of reducing the use of materials, avoiding damage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

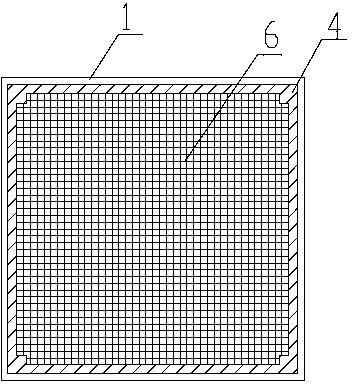

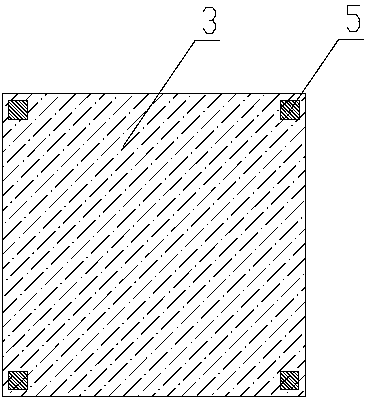

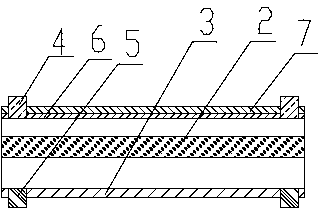

[0039] Such as Figure 1-3 As shown, a solar cell includes a battery body 1, the battery body 1 includes a battery PN junction part 2 and a back electric field part 3, a front electrode 4 and a grid line 6 are arranged on the front side of the battery body 1, and the The back of the battery body 1 is provided with a back electrode 5, the front electrode 4 is located on the edge of the upper surface of the battery body 1, the front electrode 4 is a long strip, there are four, and the front electrodes 4 are sequentially connected end to end to form a frame shape , the grid lines 6 are provided with a plurality of cross-connected ones, the grid lines 6 are located inside the frame structure surrounded by the front electrodes 4, and the two ends of the grid lines are respectively connected to the front electrodes. Preferably, the grid lines 6 are connected to each other in a cross, the front electrodes 4 are electrically connected to the grid lines 6, and there are four rear elect...

Embodiment 2

[0044] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment lies in the structure of the front electrode, and other features are the same. In this embodiment, the front electrode 4 is square, and there are four pieces, which are respectively located at the four corners of the upper surface of the battery body 1. The grid lines 6 include thick grid lines 61 and thin grid lines 62. The thick grid lines The width of 61 is half of the width of the front electrode 4 , the front electrode 4 is connected by the thick grid line 61 , and the thin grid line 62 is located inside the frame structure formed by the front electrode 4 and the thick grid line 61 . Electrodes or thick grid lines are distributed around the battery sheet, which is conducive to the collection of charges around the edge of the battery sheet (the cross-section of the pn junction), which can greatly reduce leakage current and improve battery life.

[0045] The manufacturing met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com