Motor car wheel tread sweeper shape-repair grinding device and preparation method thereof

A tread cleaning and abrasive technology, which is applied in the field of motor vehicle tread cleaner shape modification abrasive and its preparation, can solve the problems of unsatisfactory effect, large wheel damage, and rare development of shape modification abrasive, so as to repair the wheel surface Defects and out of roundness, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a shape-modifying grinding wheel for a motor vehicle tread cleaner, comprising the following steps:

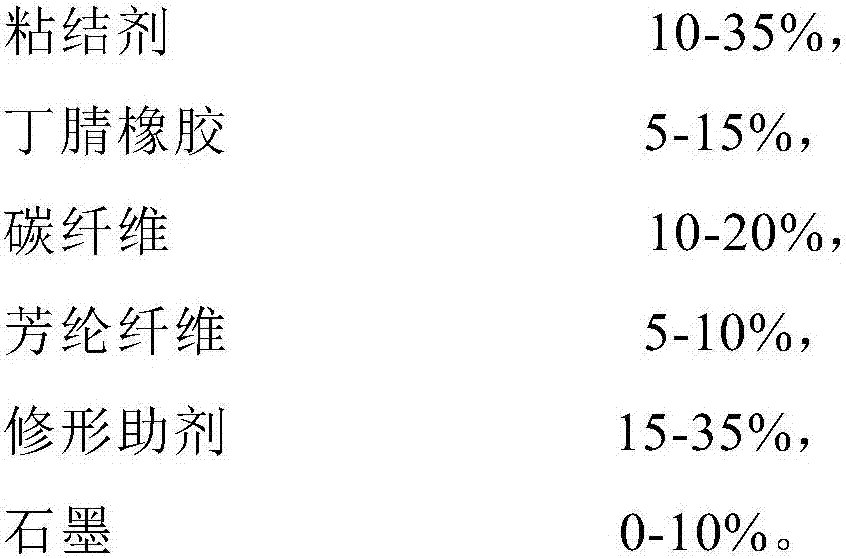

[0033] (1) Preparation of raw materials:

[0034]

[0035] (2) Preparation:

[0036] The above-mentioned raw materials are firstly added to the high-speed rake mixer in proportion and step by step, and mixed for 5 minutes. At room temperature of 120°C, the material is placed in the molding mold at a rate of 300kg / cm 2 The stress response is 400 seconds. Then sinter the molded grinding wheel at high temperature, the sintering temperature is 100°C, and the sintering time is 20 hours, and the grinding wheel can be obtained.

[0037] In the present embodiment, epoxy modified phenolic resin is selected as the bonding agent, and magnesium oxide is selected as the modifying aid. The friction coefficient of the grinding wheel obtained in this embodiment is 0.56 (constant speed type), the mass wear rate is 0.08g / MJ, and the volume wear Rate 0.10cm ...

Embodiment 2

[0039] A method for preparing a shape-modifying grinding wheel for a motor vehicle tread cleaner, comprising the following steps:

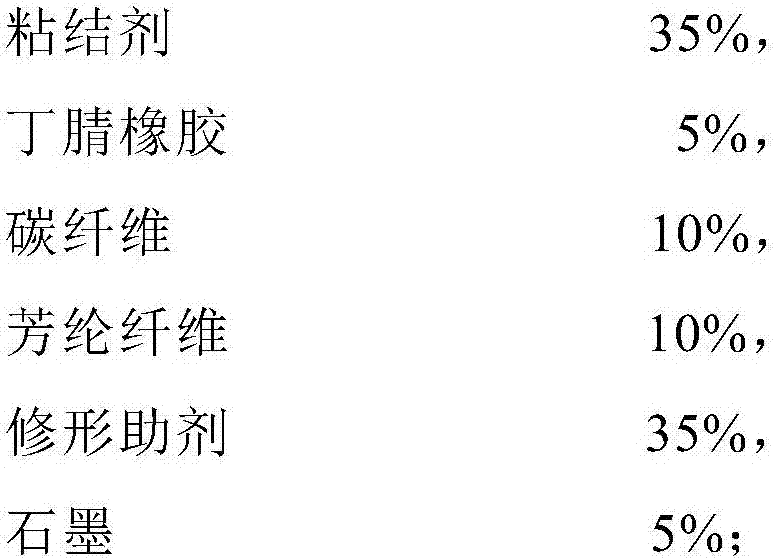

[0040] (1) Preparation of raw materials:

[0041]

[0042] (2) Preparation:

[0043] The above-mentioned raw materials are firstly added to the high-speed rake mixer in proportion and step by step for mixing, and the mixing time is 8 minutes. Put the obtained mixed material in a molding mold, control the molding temperature to 130°C, and the molding pressure to 400kg / cm 2 Press for 500s. Then sinter the formed synthetic brake sheet at high temperature, the sintering temperature is 120°C, and the sintering time is 15 hours, and the grinding wheel can be obtained.

[0044] In the present embodiment, cashew nut shell oil modified phenolic resin is selected as the binding agent, and feldspar powder is selected as the shape-modifying aid. Wear rate 0.09cm 3 / MJ, compression strength 234Mpa, compression modulus 3.02Gpa, impact strength 4.7KJ / m ...

Embodiment 3

[0046] A method for preparing a shape-modifying grinding wheel for a motor vehicle tread cleaner, comprising the following steps:

[0047] (1) Preparation of raw materials:

[0048]

[0049] (2) Preparation:

[0050]The above-mentioned raw materials are first added to the high-speed rake mixer in proportion and step by step for mixing, and the mixing time is 10 minutes. Place the obtained mixed material in a molding mold, control the molding temperature to 140°C, and the molding pressure to 600kg / cm 2 Press for 450s. Then sinter the molded synthetic brake piece at high temperature, the sintering temperature is 140°C, and the sintering time is 18 hours, and the grinding wheel can be obtained.

[0051] In this embodiment, the adhesive is selected from silicone modified phenolic resin, and the shape-modifying aid is selected from quartz. The friction coefficient of the grinding wheel obtained in this embodiment is 0.57 (constant speed type), the mass wear rate is 0.09g / MJ, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com