Pouring sealant based on phase-change microcapsules and preparation method of pouring sealant

A technology of phase-change microcapsules and potting glue, which is applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., and can solve the problem of low proportion of phase-change microcapsules, low flame-retardant grade, and no consideration of phase change The long-term stability of microcapsules and other issues can achieve the effect of improving heat storage and temperature control capabilities, improving safety, and increasing uniform and stable dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

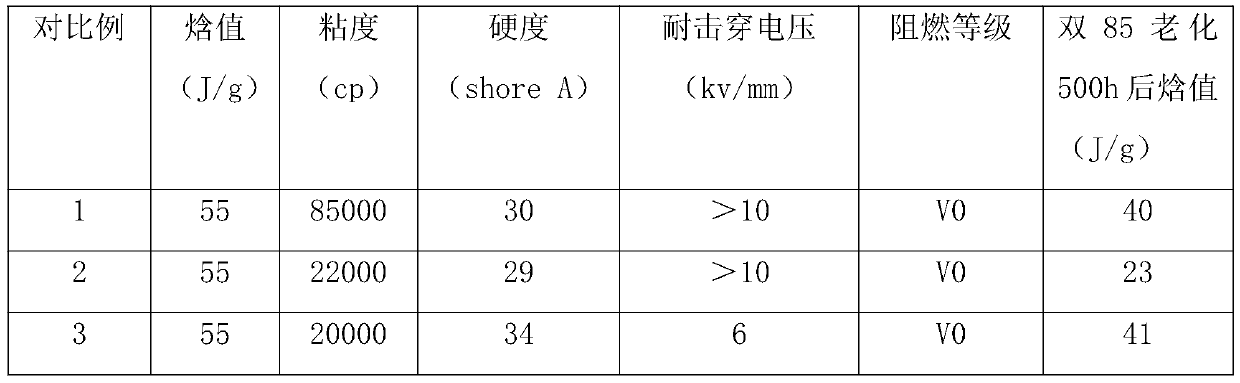

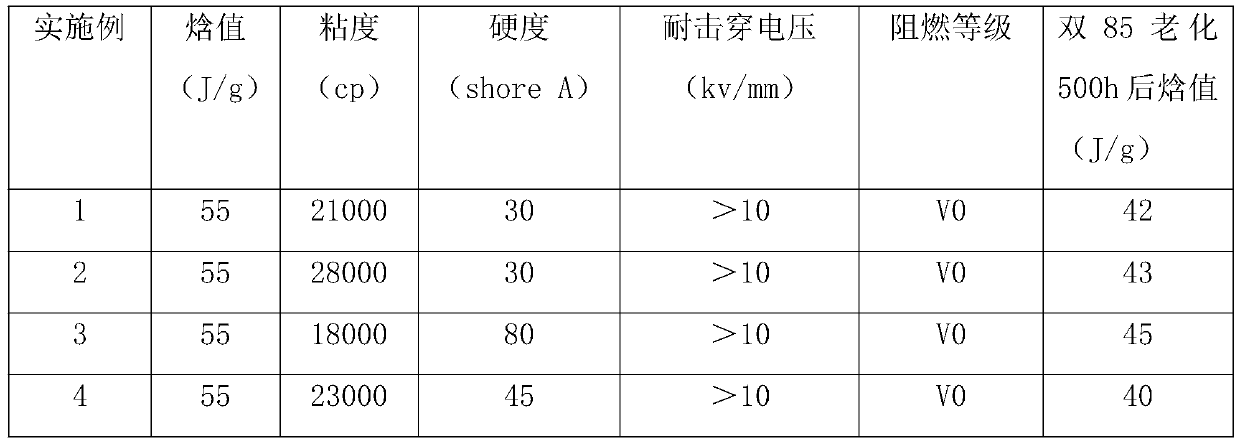

Examples

Embodiment 1

[0026] 1. Weigh 4g of dimethyldimethoxysilane, 30g of absolute ethanol, 20g of deionized water and 0.05g of acetic acid solution, and mechanically stir at room temperature for 10min at 300rpm. The hydrolyzed silane coupling agent solution is added in proportion to the phase change microcapsule filler, and the mass of the silane coupling agent is 1-3% of the mass of the phase change microcapsule. Put the two into a revolution and rotation mixer for mixing, stir for 3 minutes, the revolution speed is 2000rpm, and the rotation speed is 1000rpm. After the stirring was completed, the mixture was placed in an oven at 80° C. for 24 hours to dry, and the phase-change microcapsules treated with the silane surface were obtained after drying. The phase change temperature of the phase change microcapsules is 48° C., and the phase change enthalpy value is 220 J / g.

[0027] 2. Take 25 microliters of platinum catalyst and add it to 17g of terminal vinyl silicone oil, and mix it at a revolut...

Embodiment 2

[0030] 1. Replace dimethylmethoxysilane with methyltrimethoxysilane in Example 1, and the other operations are the same.

[0031] 2. Take 25 microliters of platinum catalyst and add it to 17g of terminal vinyl silicone oil, and mix it at a revolution speed of 1000rpm and an autorotation speed of 500rpm for 1min, then add 8g of flame retardant ammonium polyphosphate APP, 2g of carbon forming agent CFA, and aluminum hydroxide ATH 4g, 13g of surface-treated phase-change microcapsules, 5g of hydrotalcite, and 1g of calcium oxide were put into the revolution and rotation mixer again, stirred for 3 minutes, the revolution speed was 2000rpm, the rotation speed was 1000rpm, and the vacuum was evacuated to below 1kpa to obtain component A. Weigh 2g of hydrogen-containing silicone oil, add it to 15g of terminal vinyl silicone oil, and add 2 microliters of 1-ethynyl-1-cyclohexanol, mix at a revolution speed of 1000rpm and an autorotation speed of 500rpm for 1min, then add the flame retardan...

Embodiment 3

[0034] 1. Replace dimethylmethoxysilane with ethyltrimethoxysilane in Example 1, and the other operations are the same.

[0035] 2. Take 17g of epoxy resin E-51, add 8g of flame retardant ammonium polyphosphate APP, 2g of carbon forming agent CFA, 4g of aluminum hydroxide ATH, 13g of phase change microcapsules after surface treatment, 4g of hydrotalcite, calcium oxide Put 2g into the revolution and rotation mixer again, stir for 3 minutes, the revolution speed is 2000rpm, the rotation speed is 1000rpm, and the vacuum is lowered to below 1kpa to prepare the A component. Weigh 17g of polyetheramine, add 8g of flame retardant ammonium polyphosphate APP, 2g of carbon forming agent CFA, 10g of aluminum hydroxide ATH, and 13g of phase-change microcapsules after surface treatment, put them into the revolution and rotation mixer again, and stir for 3min. The revolution speed is 2000rpm, the autorotation speed is 1000rpm, and the vacuum is evacuated to below 1kpa to prepare the B compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com