Axial micro-catalytic reaction unit and application thereof

A catalytic reaction and micro-reaction channel technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve problems such as short residence time, local overheating, and large height and diameter, and achieve Guaranteed smooth operation, extended service life, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

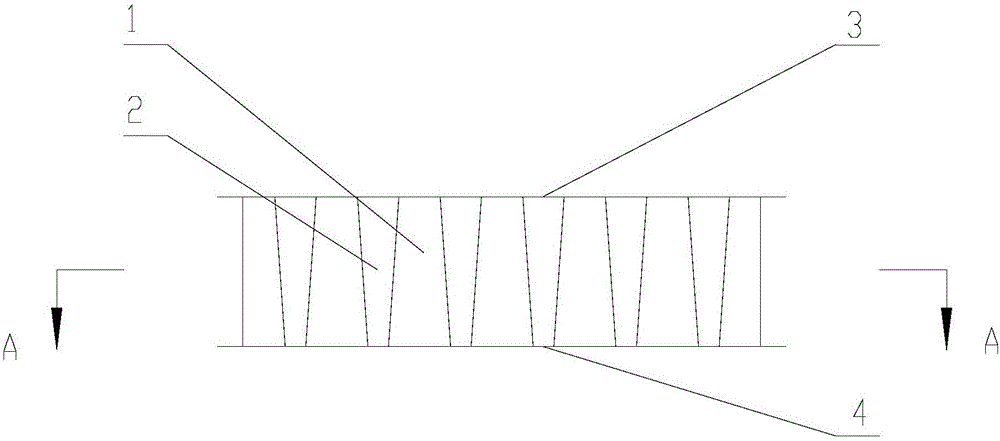

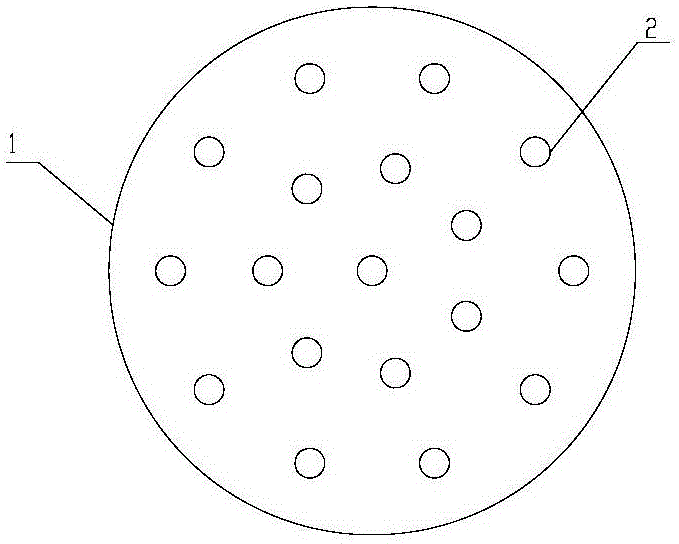

[0051] Such as figure 1 As shown, the axial micro-catalytic reaction unit adopted in this embodiment includes a cylindrical column 1 composed of a top sealing plate, a bottom sealing plate and side surfaces. The up and down of the column body 1 are in fluid communication through the micro-reaction channel 2 . Such as Figure 9 As shown, in the micro-reaction channel 2 of the conical tube structure, the tube wall is coated with nickel, an active component of methanation reaction, and the two ends are respectively sealed and connected with the top sealing plate and the bottom sealing plate of the column body 1 .

[0052] The height of the axial micro-catalytic reaction unit is 100 mm, and the diameter is 340 mm. The length of the micro-reaction channel of the tapered tube is 100 mm, the diameter of the inlet of the tapered tube is 10 mm, and the diameter of the outlet is 4 mm. The proportion of the column volume is 41.6%.

[0053] The axial micro-catalytic reaction unit can b...

Embodiment 2

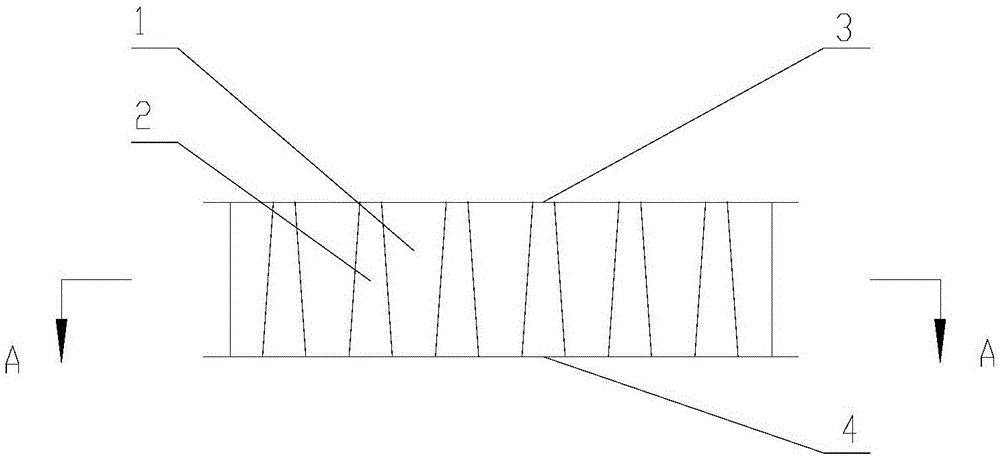

[0055] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the diameter of the tapered pipe inlet is 4mm, and the diameter of the outlet is 10mm. This type of reactor is suitable for chemical reactions with increased reaction volume, such as cyclohexane dehydrogenation, ethylbenzene dehydrogenation Hydrogen and ammonia decomposition reactions.

[0056] The axial micro-catalytic reaction unit is used for cyclohexane dehydrogenation reaction. The dehydrogenation reaction of cyclohexane is an endothermic reaction with volume increase. Cyclohexane enters the conical tube whose inner surface is coated with platinum metal from above the axial micro-catalytic reaction unit, and the dehydrogenation reaction occurs on the surface of the platinum metal catalyst, from The product outlet exits the conical tube. Cyclohexane flows from the inside to the outside, and the reaction channel gradually becomes larger, which increases the driving force for th...

Embodiment 3

[0058] Such as Figure 6 and Figure 7 As shown, the difference between embodiment 3 and embodiment 1 is that three axial micro-catalytic reaction units arranged side by side composed of quadrangular column 1 are used for the methanation reaction together, and the top of the axial micro-catalytic reaction unit Both the sealing plate and the bottom sealing plate are hermetically connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com