Axial micro-channel coupling reactor and applications thereof

A technology of reactors and microchannels, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical processes, etc., can solve problems such as slow heat transfer, obvious amplification effect, and local overheating, and achieve reduction The effect of production cost, simplification of process flow and reduction of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] According to a specific implementation manner of the first aspect of the present invention, the cylinder 6 can be composed of an upper sealing plate and a lower sealing plate, and its side wall can overlap with a part of the side wall of the housing 1, or can overlap with the side wall of the housing 1. Wall-tight connection.

[0045] According to the first aspect of the present invention, under the same reaction conditions and reactor diameter, increasing the number of columns 6 can increase the contact time between the reaction gas and the catalyst, reduce the flow rate of the reaction gas, and improve the effect of the conversion rate, so it can be based on actual conditions. According to the situation, the number of columns 6 can be adjusted, and the number of columns 6 can be 2-500, preferably 2-50.

[0046] According to the first aspect of the present invention, in order to enable the axial microchannel coupling reactor to be used for exothermic and endothermic re...

Embodiment 1

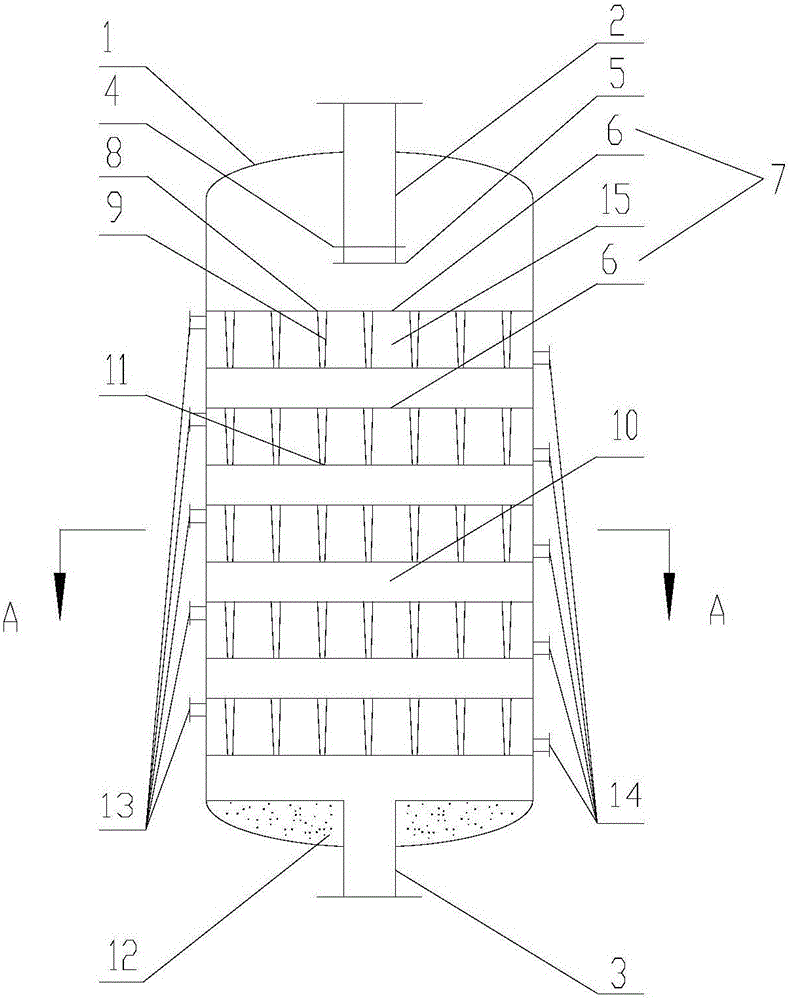

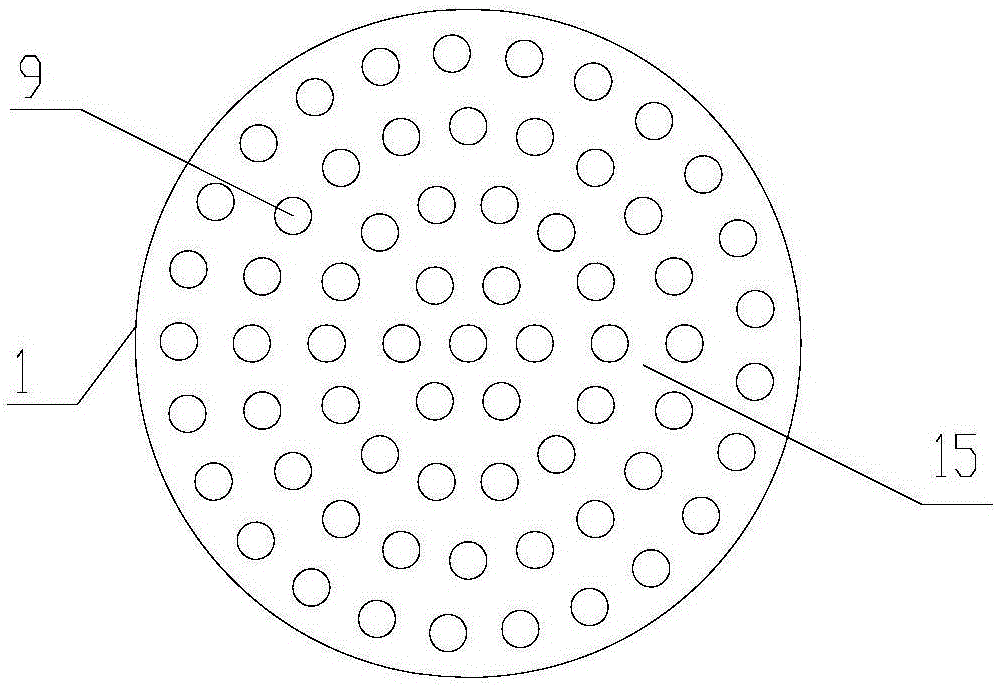

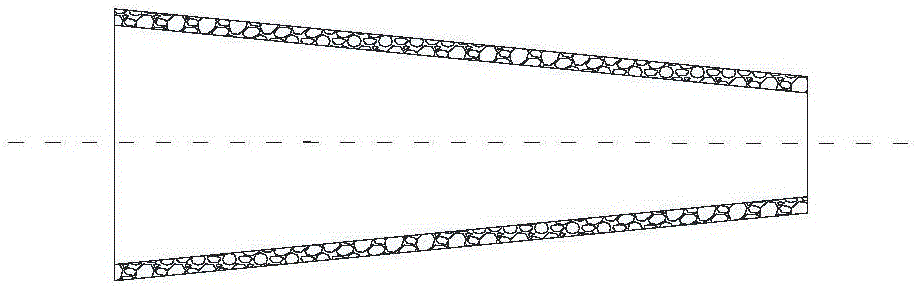

[0058] Such as figure 1 As shown, the axial microchannel coupling reactor used in this embodiment includes a pressure-bearing shell 1 with a 1# straight pipe 2 at the upper end and a 2# straight pipe 3 at the lower end, and a lower part of the 1# straight pipe 2. There is a first gas distributor 4 and a second gas distributor 5 . The axial catalytic reaction unit is arranged below the 1# straight pipe 2 in the housing 1 . Such as figure 2 As shown, the axial catalytic reaction unit is an axial flow reaction zone composed of a conical tube micro-reaction channel 9 whose inner surface and outer surface are respectively coated with catalyst. Such as image 3 As shown, the two ends of the micro-reaction channel 9 of the tapered tube structure are sealed and connected with the upper sealing plate and the lower sealing plate of the cylinder 6 respectively. Between the axial catalytic reaction unit and the bottom surface of the casing 1 is provided a heat insulating material are...

Embodiment 2

[0068] The structural parameters of the axial microchannel coupled reactor in this embodiment are the same as those of the reactor in Embodiment 1. The axial microchannel coupled reactor can be used for methane catalytic combustion reaction and methane steam reforming reaction. Since methane steam reforming hydrogen production reaction is an endothermic reaction with increased volume, it is arranged on the inner surface of the microchannel reactor The catalytic combustion reaction of methane is a strong exothermic reaction of equal volume, which is carried out on the outer surface of the microchannel reactor. The inner surface of the microchannel is coated with Pt, the active component of hydrogen production by steam reforming of methane, with a loading capacity of 0.2g / m 2 ; Load methane catalytic combustion active component Pd on the outer surface of the microchannel, and the load is 0.09g / m 2 .

[0069] Since the methane steam reforming hydrogen production reaction with i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com