Methanation reactor and methanation process

A methanation reactor and reactor technology, applied in chemical instruments and methods, organic chemistry, petroleum industry, etc., can solve problems such as unbearable high pressure, large pressure drop in reactor, difficulty in eliminating thermal expansion and contraction stress, etc., to achieve The effect of short residence time, prolonging the service life and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

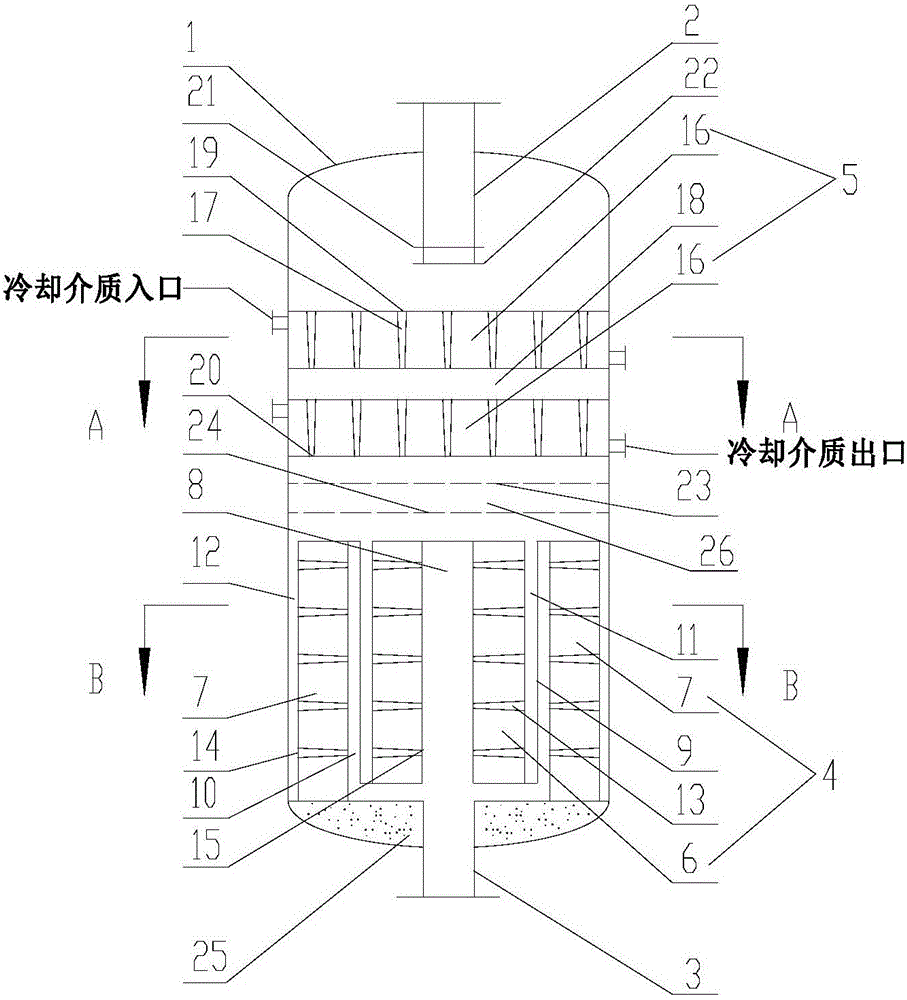

[0076] Such as Figure 4 As shown, the reaction device of this embodiment consists of 1# main methanation reactor 27, 2# main methanation reactor 28, supplementary methanation reactor 29, steam superheater 30, boiler feed water heater 31, 2# cooler 32. 1# cooler 33, product separator 34 and steam drum 35 are connected. The two main methanation reactors are connected in parallel and share a steam drum 35 with the supplementary methanation reactor.

[0077] The operation steps are as follows:

[0078] a. H 2 The / CO volume ratio is 3.0 (M=3.0), the pressure is 3.5MPa, the synthesis gas temperature is 250°C, and the total volume flow rate is 10m 3 / h, divided into two streams to enter the main methanation reactor, one stream enters the 1# main methanation reactor 27 for the main methanation reaction, and the other synthesis gas enters the 2# main methanation reactor 28 for the main methanation reaction, The micro-reaction channels of the two main methanation reactors have the...

Embodiment 2

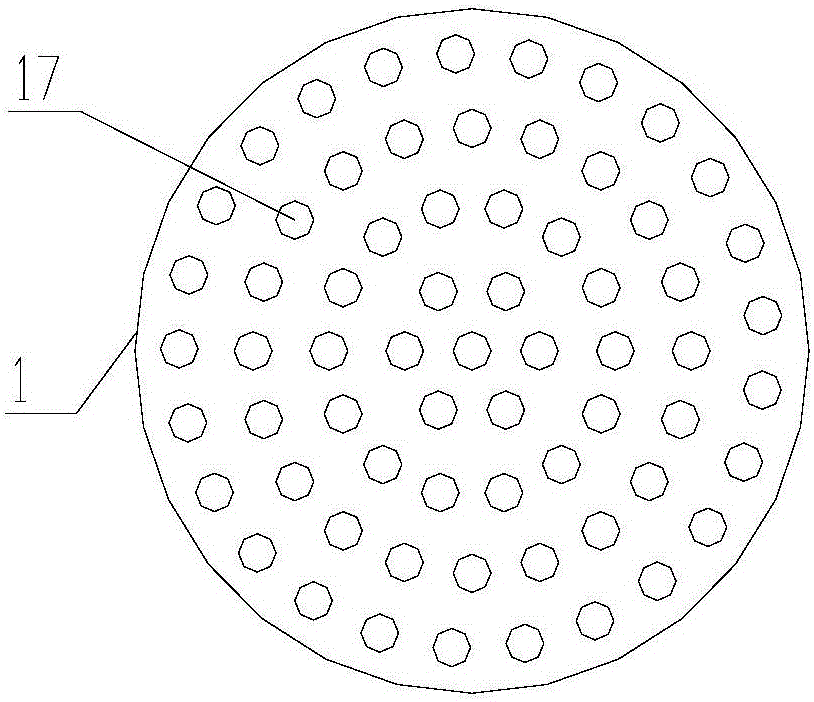

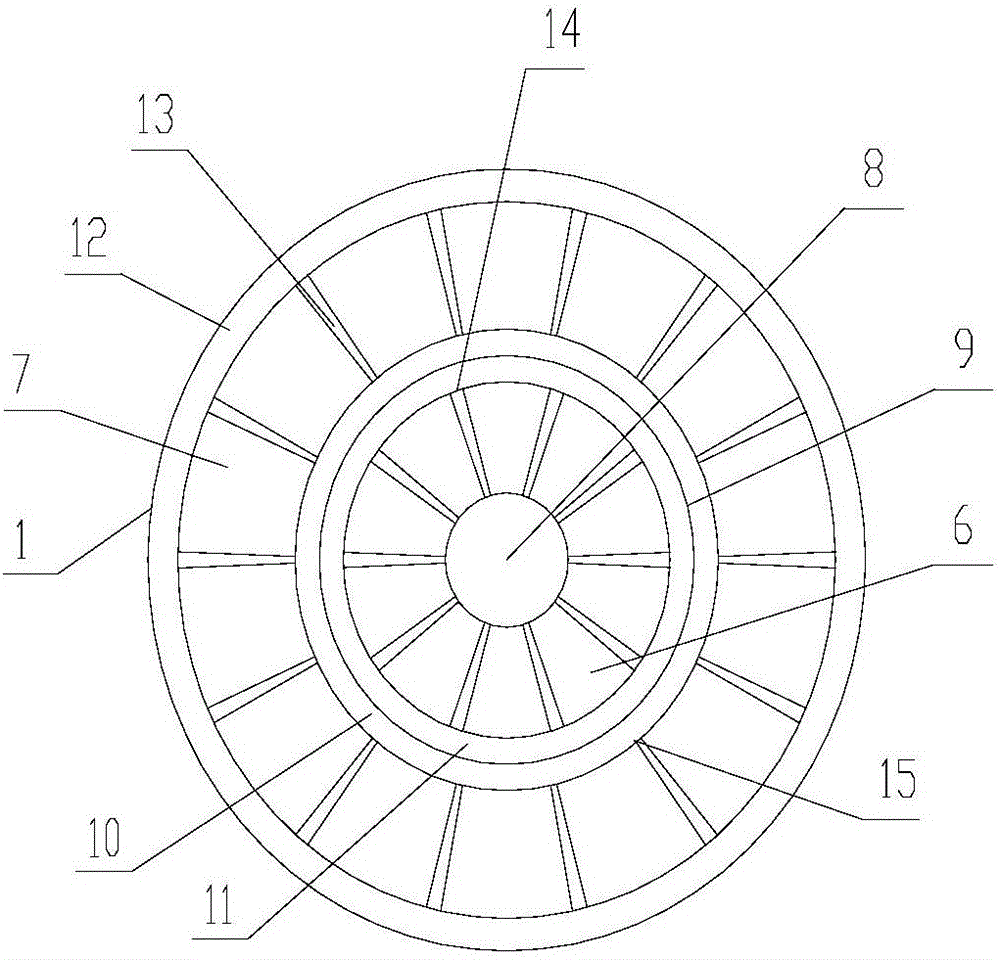

[0089] Such as Figure 5-7 As shown, the difference between embodiment 2 and embodiment 1 is that the vertical catalytic reaction unit of the methanation reactor is located above the horizontal catalytic reaction unit, and the horizontal catalytic reaction unit is not provided with a cooling medium inlet, a cooling medium outlet and a cooling medium pipeline .

[0090] Such as Figure 8 As shown, the difference between Example 2 and Example 1 is that the boiler feed water is preheated by the boiler feed water heater 31 and then exchanges heat with the steam superheater 30 instead of being sent to the methanation reactor for cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com