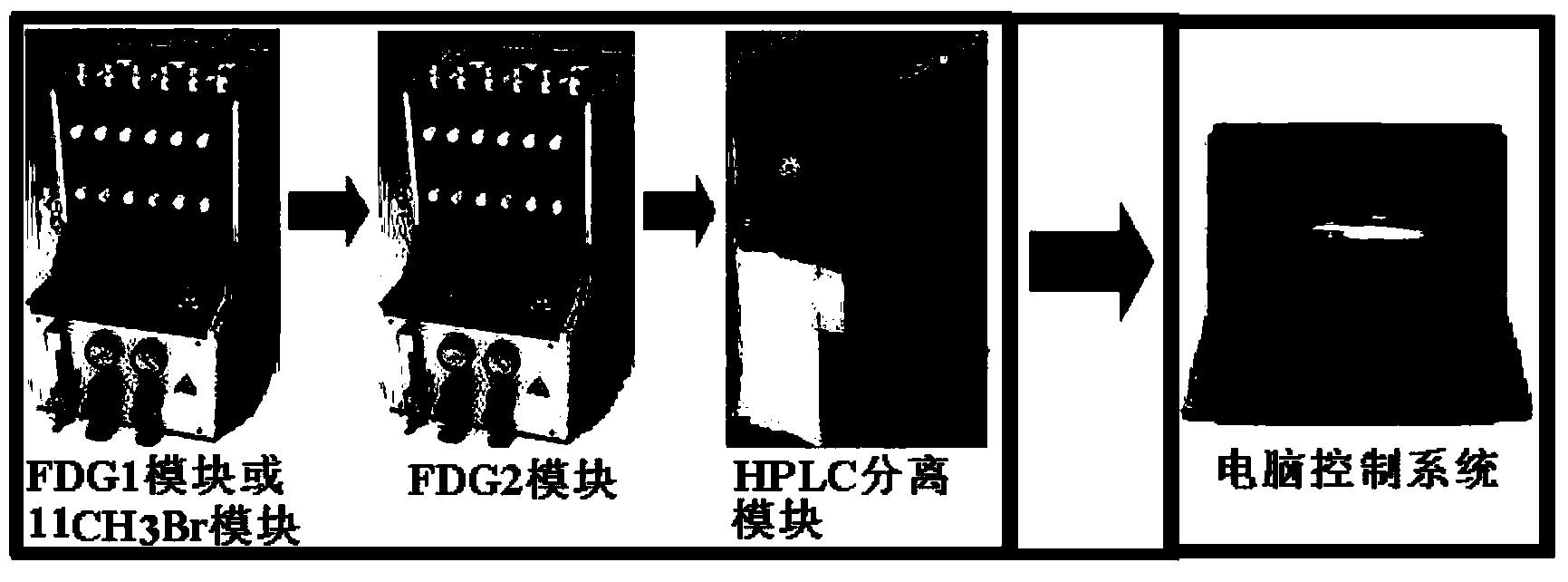

Small modular multifunctional automatic 18F labelling PET (positron emission tomography) drug synthesizer

A modular technology for drug synthesis, applied in chemical instruments and methods, isotope introduction of organic compounds, organic chemistry, etc., can solve the problems of unsuitable PET drug production, high maintenance and warranty costs, and large synthesizer volume, so as to ensure that the instrument Safety, easy installation, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

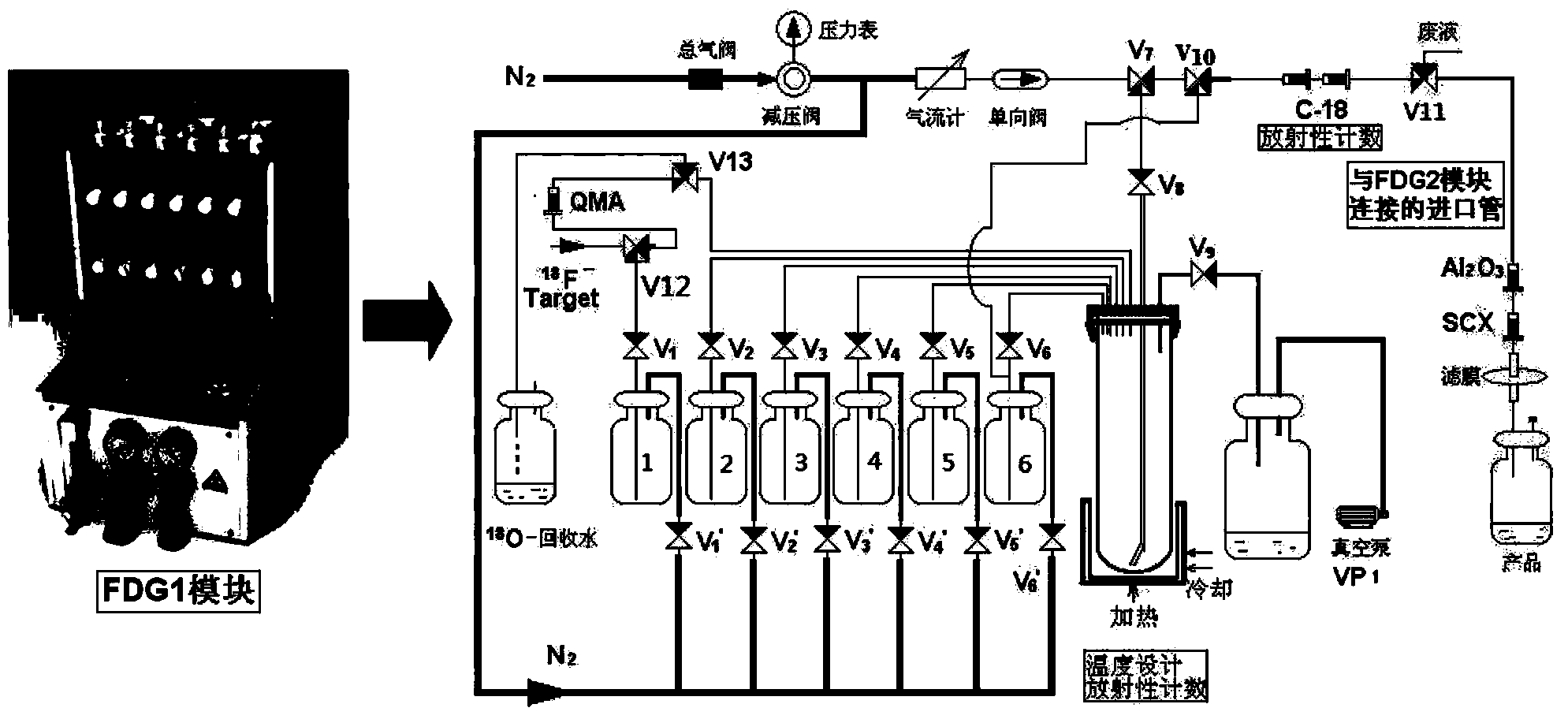

[0045] Embodiment 1 FDG automatic synthesis

[0046] self-test. Adjust the pressure of the cylinder pressure valve to be greater than 0.5MPa, add N 2 The pressure is 0.2MPa, blowing air to evaporate N 2 The flow rate is 80-100ml / min; add water, acetonitrile, acetonitrile and water 2-3ml to No. 1, No. 2, No. 3 and No. 5 bottles respectively. After connecting the pipelines, installing the waste bottle and receiving bottle, start the self-test procedure. Check heating and gas delivery for proper operation.

[0047] Preparation before production.

[0048] 1. Prepare the QMA cartridge. Take 0.3M NaHCO 3 (or Na 2 CO 3 ) 10ml, passed through a Sep Pak light QMA cartridge to remove excess liquid. Take 10ml of water for injection, pass through the QMA column, and get rid of excess liquid. Or take another 10ml of chromatographically pure acetonitrile, pass through the QMA column, and remove the excess liquid.

[0049] 2. C-18 cartridge processing. Take 10ml of absolute ethan...

Embodiment 2

[0063] Example 2 18F-FLT automatic synthesis

[0064] Preparation before production. Edit 3'-deoxy-3'- in the package 18 F-fluorothymidine (18F-FLT) automated synthesis procedure ( figure 2 FDG1-fluorinated part and HPLC part). Install Sep Pak Light QMA Cartridges and Sep Pak Al in place 2 o 3 Neutral separation cartridge. Add K222 solution to No. 1 bottle, that is, add 1.5ml of acetonitrile water (volume ratio 10 / 1) solution, containing 15mg of phase transfer catalyst amino polyether 4,7,13,16,21,24-hexaoxa-1 , 10-diazabicyclo[8,8,8]hexacane (Kryptofix2.2.2, K222) and 3mg K 2 CO 3 ; Add 15 mg of the precursor 3-N-t-tert-butoxycarbonyl-1-[5'-O-(4,4'-dimethoxytrityl)-2'-deoxy-3 to bottle No. 3 '-O-(4-nitrobenzenesulfonyl)-β-D-threo-furanosyl]thymine in acetonitrile solution (1mL); add 1mol / L hydrochloric acid (1mL) to bottle No. 4; add 1mol / L sodium hydroxide solution (1mL); add ethanol-water eluent (1mL) with a volume ratio of less than 10:90 into No. 6 bottle. Clos...

Embodiment 3

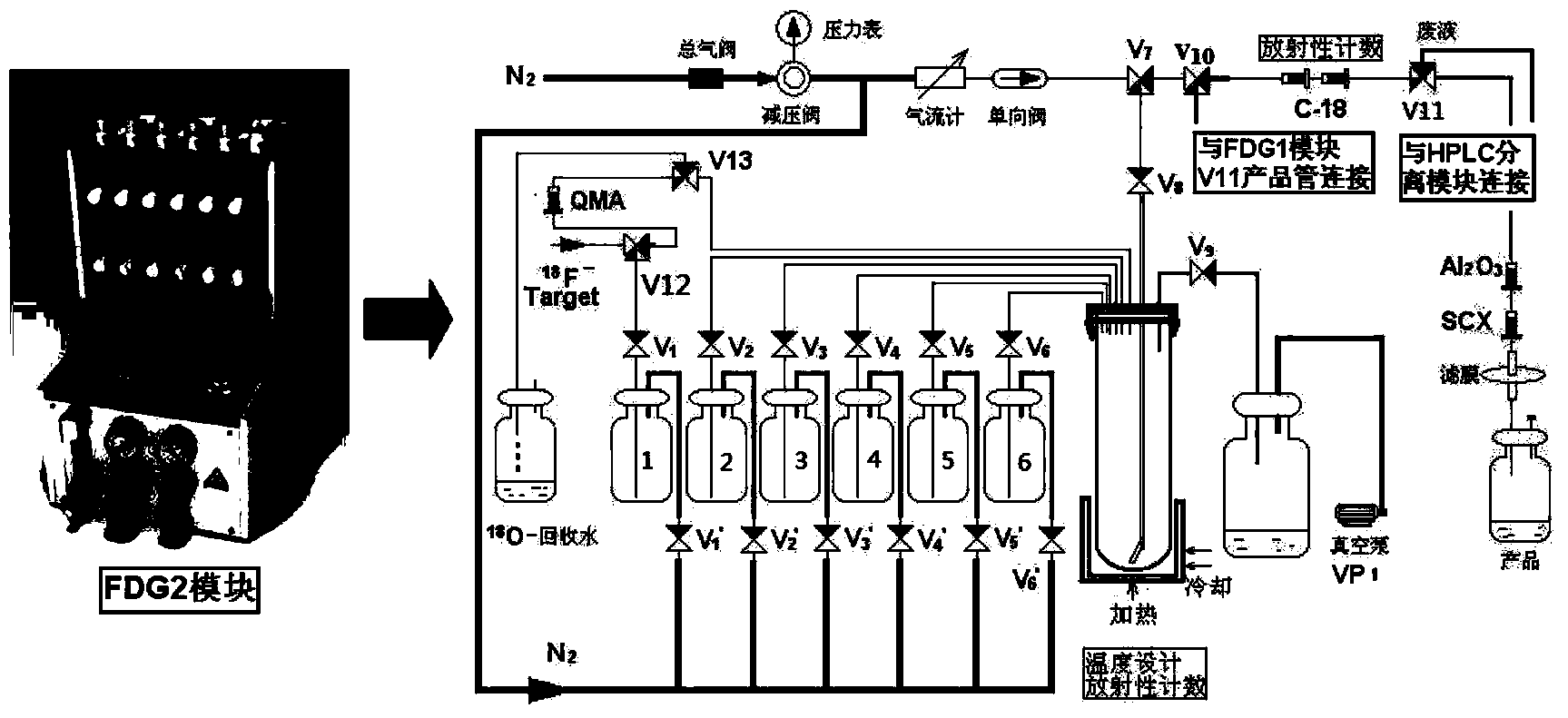

[0071] Example 3 18 F-FCH automatic synthesis

[0072] Preparation before production. Edit (N-18F-fluoromethyl)choline in the package ( 18 F-FCH) automated synthesis program ( figure 2 FDG1-fluorinated part and FDG2-converted part). Install 1 Sep Pak Light QMA cartridge, 3 Sep Pak plus SiO2 cartridges, 1 Sep Pak plus tC18 cartridge and Sep Pak CM cartridge at a suitable location. FDG1-fluorinated part: add 1.5mL K222 solution to bottle No. 1; add dibromomethane (300 μL) in acetonitrile (2 mL) solution to bottle No. 3. FDG2-conversion part: Load N,N-dimethylethanolamine 0.4mL in Sep Pak plus tC18 cartridge; add 10mL ethanol to No. 1 bottle; add 10mL water to No. 2 bottle; add 3mL saline to No. 3 bottle. Close the thermal cell door.

[0073] Automated manufacturing. Select the 18F-FCH synthesis program in the menu of the software, press the "start operation" button, and complete it under the control of the computer 18 F-FCH automated synthesis.

[0074] (1)[K / K222]+ 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com