Method for manufacturing rotary optical fiber and rotary fiber winding device

A technology for rotating optical fibers and manufacturing methods, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of methods for reducing optical fiber birefringence, unsatisfactory mechanical properties, and difficult to achieve, and achieve good performance stability and use reliability. Easy to integrate applications, easy to handle the effects of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

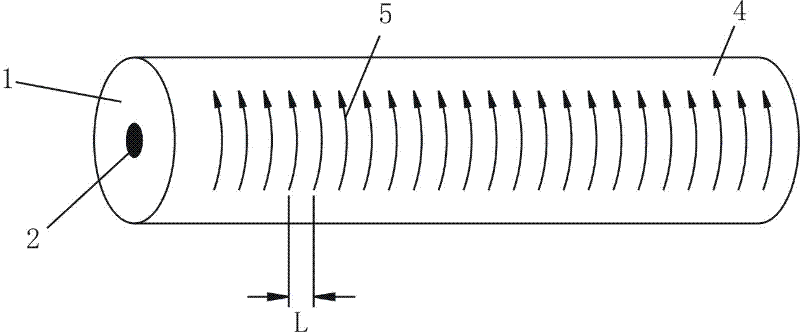

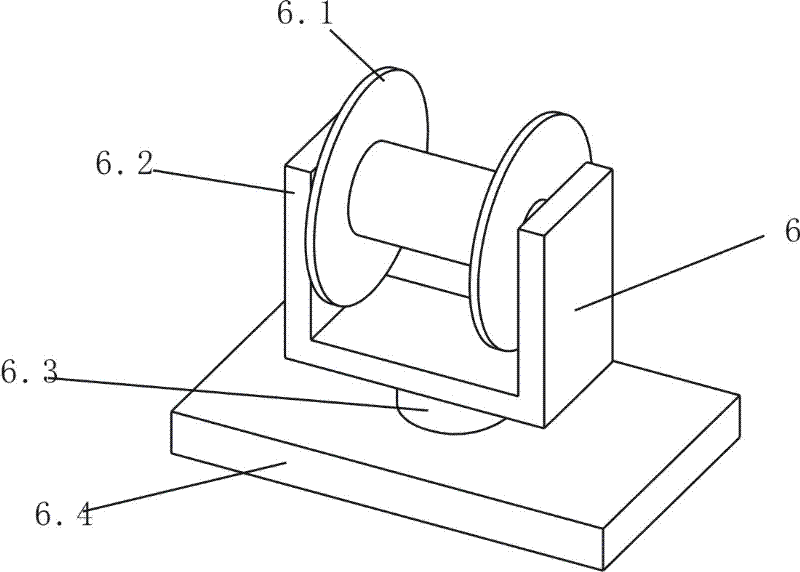

[0035] Select the G.652D type single-mode optical fiber preform, place the optical fiber preform 8 in the fiber drawing tower 7, and use the rotating fiber receiving device 6 provided by the present invention to draw an ultra-low birefringence single-mode optical fiber with rotation characteristics . Table 1 shows the birefringence of the manufactured single-mode optical fiber and the measured birefringence of each optical fiber under different drawing rotation parameters.

[0036] Table I

[0037] Example Optical fiber preform outer diameter (mm) Drawing speed of optical fiber preform (m / min / ) Horizontal rotation speed of fiber collection disc (r / min) Fiber cladding diameter after drawing (μm) Fiber rotation pitch L after drawing (mm) Tested fiber birefringence 1 15 50 1000 125 50 ~9.3×10 -7 2 15 10 800 125 12.5 ~5.1×10 -8 3 15 1 1000 125 1 ~6.2×10 -9 4 10 50 1000 125 50 ~8.6×10 -7 5 10 10 800 125 12.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com