Calibration method of touch display screen

A touch screen, calibration method technology, applied in the input/output process of data processing, instruments, electrical digital data processing and other directions, can solve problems such as being unsuitable for mass production, expensive calibration fixtures, and unfavorable for customers to seize the market. , to improve the calibration efficiency and calibration accuracy, the calculation speed is fast, and the touch effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

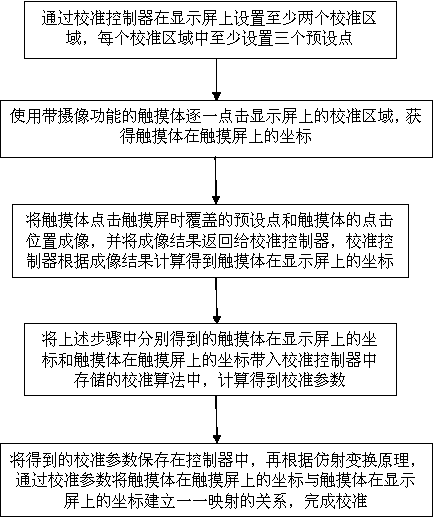

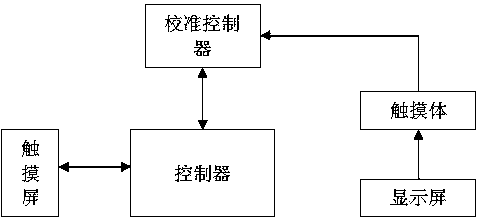

[0035] A method for calibrating a touch screen, comprising the steps of:

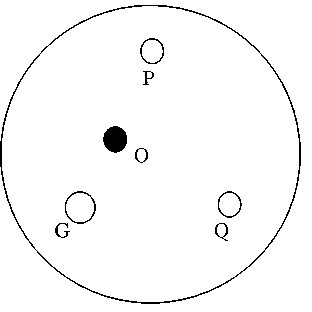

[0036] a. Set four calibration areas on the display screen through the calibration controller, and set at least three preset points with known coordinates in each calibration area, such as image 3 The three preset points of G, P, and Q are shown, and the coordinates of the preset points in each calibration area on the display are stored in the calibration controller, where four calibration areas can form a quadrilateral, and four The calibration area is located on the four corners of the quadrilateral;

[0037] b. Use the touch body with camera function to click the calibration area on the display screen one by one, and set the touch body to click on the O point in the calibration area (such as image 3 As shown), after the touch body clicks the four calibration areas in turn, a total of four sets of coordinates of the touch body on the touch screen are obtained. When the touch body clicks the calibra...

Embodiment 2

[0051] A method for calibrating a touch screen, comprising the steps of:

[0052] a. Set two calibration areas on the display screen through the calibration controller, the two calibration areas are set diagonally on the display screen, and at least three preset points are set in each calibration area, such as image 3 The three preset points of G, P, and Q are shown, and the coordinates of the preset points in each calibration area on the display are stored in the calibration controller;

[0053] b. Use the touch body with camera function to click two calibration areas in turn, each calibration area is clicked at least once, set the touch body to click on the O point of the calibration area (such as image 3 As shown), after the touch body clicks the two calibration areas in turn, a total of four sets of coordinates of the touch body on the touch screen are obtained. When the touch body clicks the calibration area, it uses the center of the touch body to click the calibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com