Continuous heat processing technology of steel wire

A technology of steel wire and process, which is applied in the field of continuous heat treatment process of steel wire, can solve the problems of low production efficiency, high production cost, large inventory, etc., and achieve the effect of tight connection, reduction of production cost and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

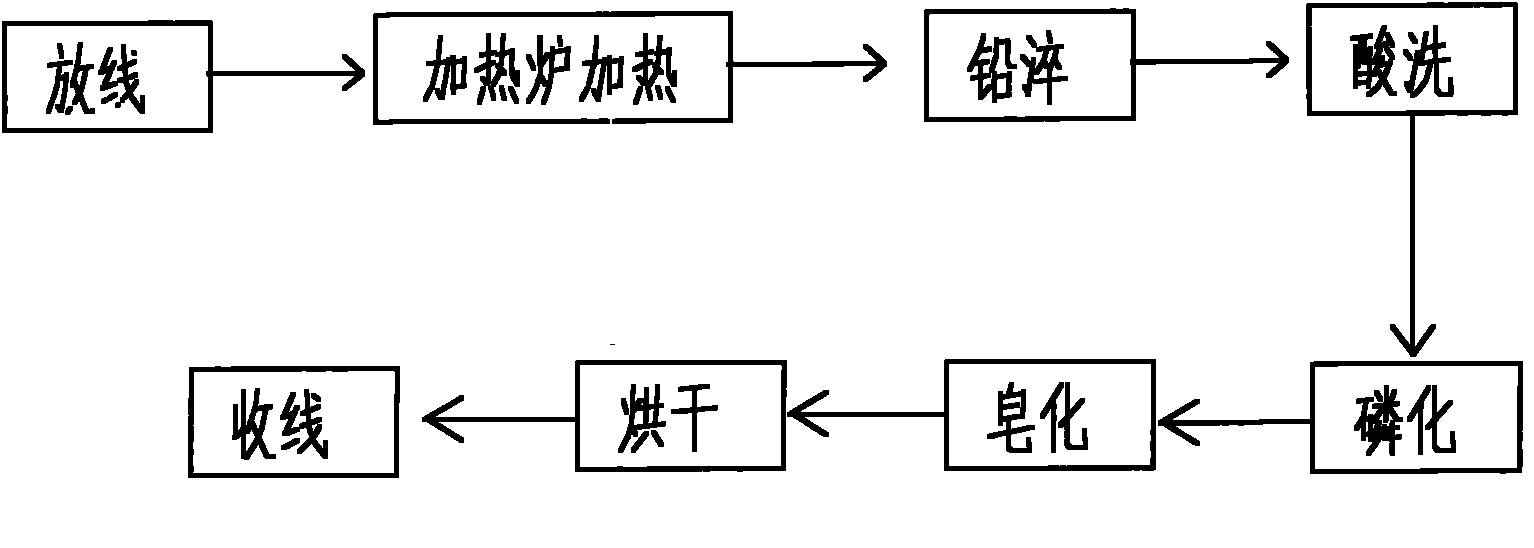

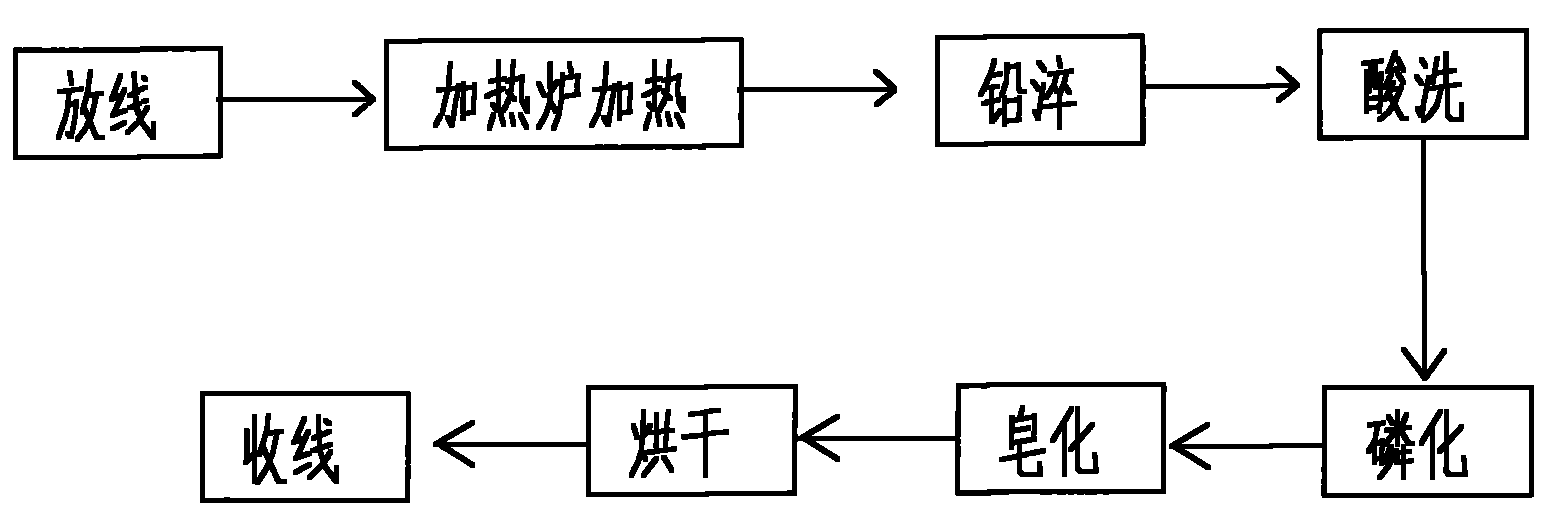

[0020] Such as figure 1 Shown, a kind of continuous heat treatment process of steel wire, comprises the following steps:

[0021] (1) Furnace heating: the steel wire is unwound through the pay-off frame, and then penetrates into the heat treatment furnace, and in the heating furnace, it is heated in the first stage at 970-990°C, second-stage heating at 950-970°C, three-stage heating at 935-955°C, 920~940℃ soaking section heating, heating time is 2min;

[0022] (2) Lead quenching: the steel wire heated by the heating furnace is penetrated into the lead pool, and the lead quenching is carried out through the molten lead at 545-555 °C, and the lead quenching time is 0.5min;

[0023] (3) Pickling: The lead-hardened steel wire is inserted into the pickling tank, and pickled with hydrochloric acid, and the pickling time is 1.5 minutes;

[0024] (4) Phosphating: the pickled steel wire is penetrated into the phosphating pool, and phosphate is used for phosphating, and the phosphatin...

Embodiment 2

[0028] Such as figure 1 Shown, a kind of continuous heat treatment process of steel wire, comprises the following steps:

[0029] (1) Furnace heating: the steel wire is unwound through the pay-off frame, and then penetrates into the heat treatment furnace, and in the heating furnace, it is heated in the first stage at 970-990°C, second-stage heating at 950-970°C, three-stage heating at 935-955°C, 920~940℃ soaking section heating, heating time is 3min;

[0030] (2) Lead quenching: the steel wire heated by the heating furnace is penetrated into the lead pool, and the lead quenching is carried out through the molten lead at 545-555 °C, and the lead quenching time is 1 minute;

[0031] (3) Pickling: The lead-hardened steel wire is inserted into the pickling tank, and pickled with hydrochloric acid, and the pickling time is 2.5 minutes;

[0032] (4) Phosphating: the pickled steel wire is penetrated into the phosphating pool, and phosphate is used for phosphating, and the phosphat...

Embodiment 3

[0036] Such as figure 1 Shown, a kind of continuous heat treatment process of steel wire, comprises the following steps:

[0037] (1) Furnace heating: the steel wire is unwound through the pay-off frame, and then penetrates into the heat treatment furnace, and in the heating furnace, it is heated in the first stage at 970-990°C, second-stage heating at 950-970°C, three-stage heating at 935-955°C, 920~940℃ soaking section heating, heating time is 2.5min;

[0038] (2) Lead quenching: the steel wire heated by the heating furnace is penetrated into the lead pool, and the lead quenching is carried out through the molten lead at 545-555 °C, and the lead quenching time is 0.7min;

[0039] (3) Pickling: The lead-hardened steel wire is inserted into the pickling tank, and pickled with hydrochloric acid, and the pickling time is 2 minutes;

[0040] (4) Phosphating: the pickled steel wire is penetrated into the phosphating pool, and phosphate is used for phosphating, and the phosphatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com