Skeleton cable

A skeleton and skeleton technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of joint failure, increase line loss, uneconomical, etc., and achieve the effects of reducing expenditure, increasing reliability, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

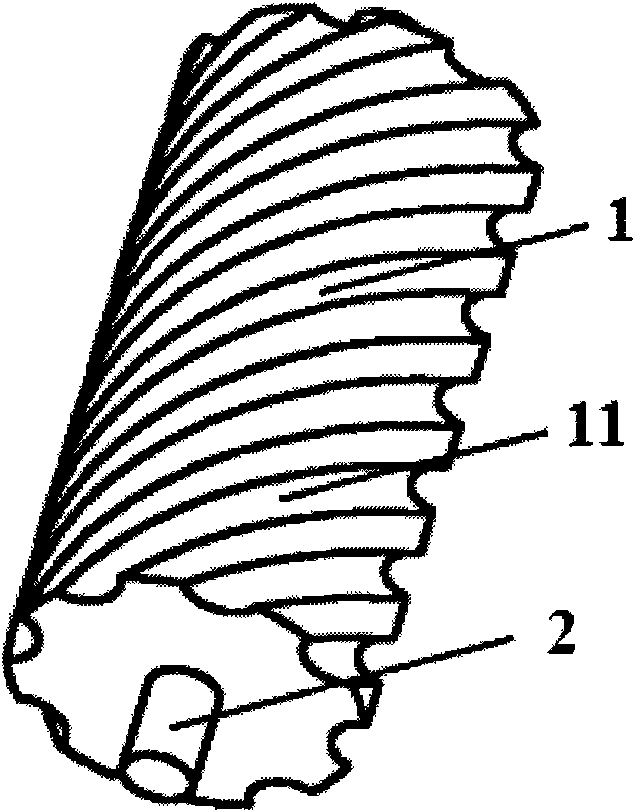

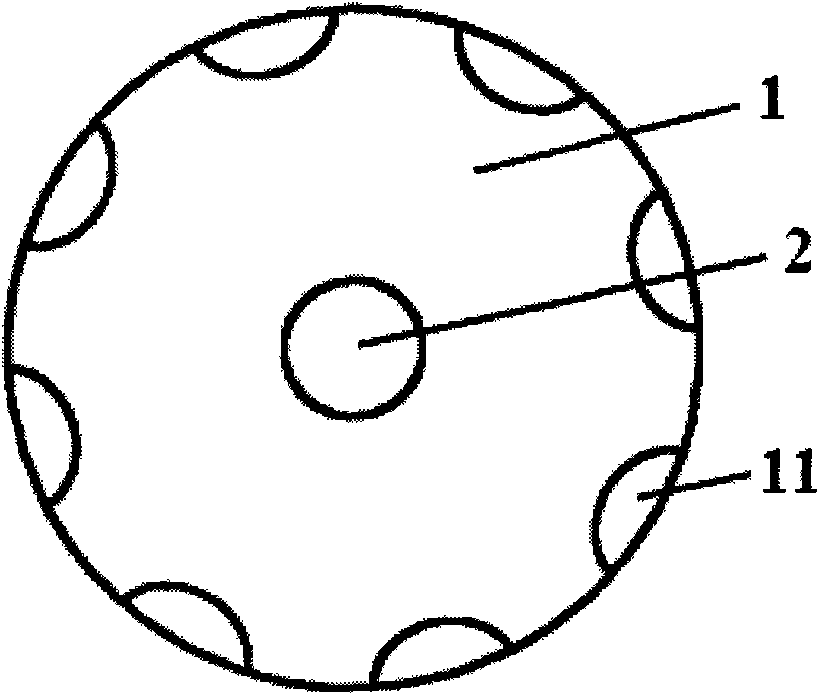

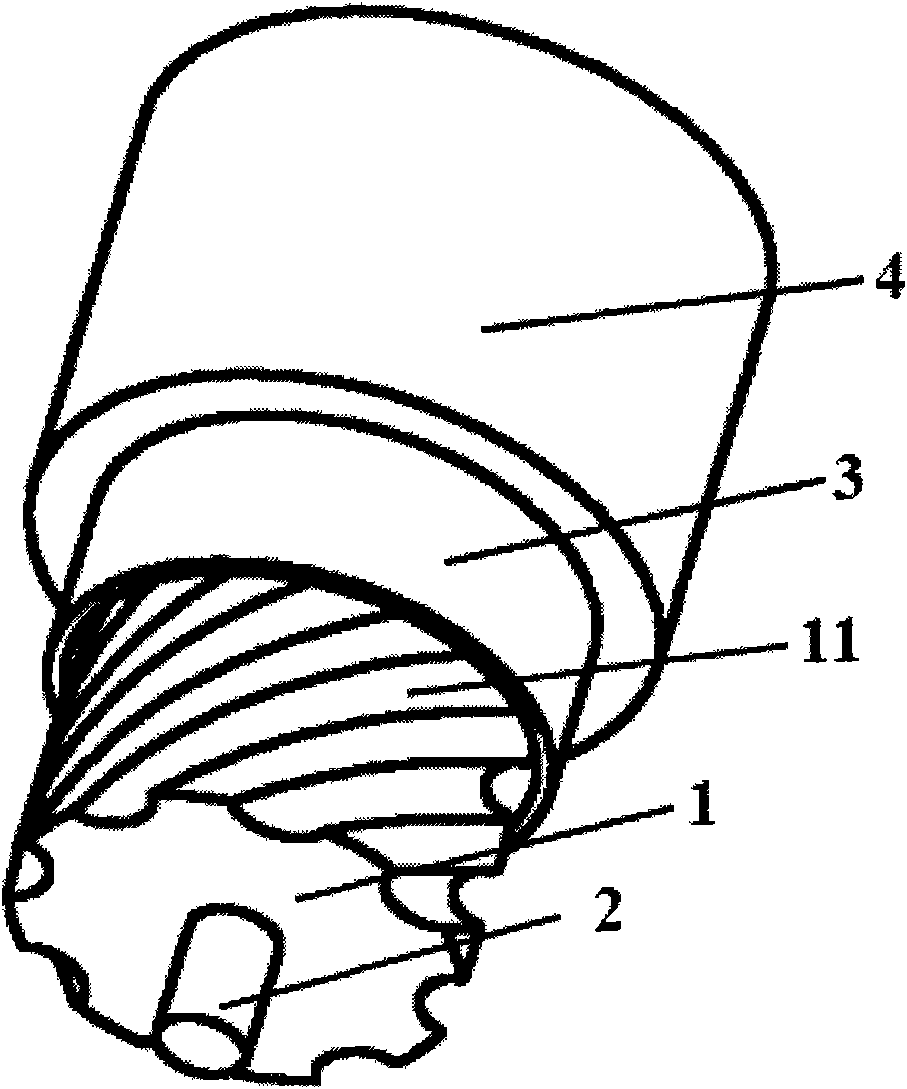

[0025] please see figure 1 , figure 2 and image 3 , a skeleton cable, which includes a cable core, is characterized in that: it also includes a skeleton 1, a protective layer 3 and an outer sheath 4; eight skeleton grooves 11 are provided on the skeleton, and the protective layer 3 is located on the skeleton Outside, the outer protective layer 4 is located outside the protective layer; the cable core is located in the skeleton groove 11, and the metal reinforcement 2 is also arranged inside the skeleton. The skeleton groove is located at the periphery of the skeleton and is evenly distributed. It is crescent-shaped, and the distribution of skeleton grooves along the skeleton axis is spiral. The pitch of the above-mentioned skeleton grooves along the skeleton axis is 200 mm. The skeleton material is polyethylene plastic, and the protective layer is non-woven fabric. The axial direction and longitudinal direction of the cable are covered outside the frame, the material of th...

Embodiment 2

[0027] please see Figure 4 and Figure 5 , basically the same as the first embodiment, except that the skeleton has four skeleton grooves 11 on the skeleton.

Embodiment 3

[0029] please see Figure 6 , a framed cable, which includes five sets of cable cores 5, characterized in that: it also includes a frame 1, a protective layer 3 and an outer sheath 4; five frame grooves 11 on the frame, the protective layer 3 Located outside the frame, the outer sheath 4 is located outside the protective layer; the cable core 5 is located in the frame groove 11, and the inside of the frame is also provided with a metal reinforcement 2, and the frame groove is located on the periphery of the frame, which is evenly distributed, and the frame groove The cross-sectional shape of the frame is trapezoidal, and the distribution of the frame grooves along the axis of the frame is spiral. The pitch of the above-mentioned frame grooves along the axis of the frame is 500 mm. The layer is covered outside the frame longitudinally along the axial direction of the frame. The material of the protective layer is low-smoke halogen-free polyethylene plastic. The cable core is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com