Panel for the production of a swimming pool

A technology for swimming pools and processes, applied in swimming pools, public buildings, buildings, etc., can solve the problems of increasing the size and distortion of modular panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

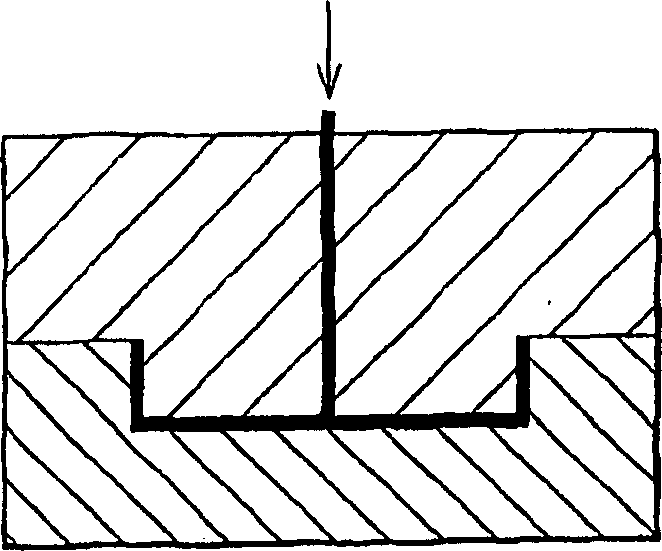

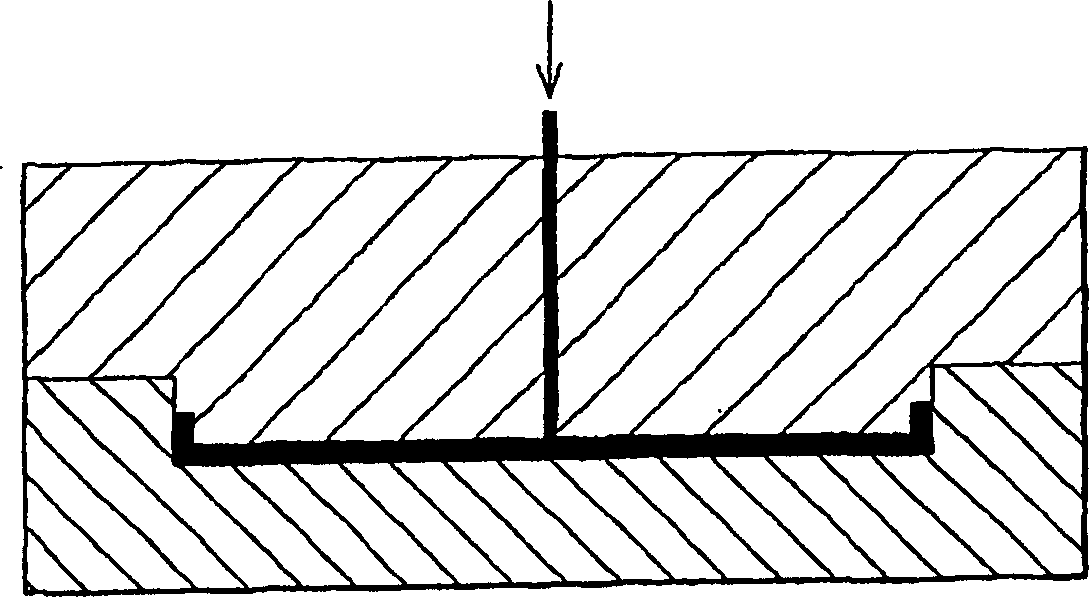

[0033] As explained, according to the essential feature of the present invention, each modular plate, indicated as a whole by (1), is made of plastic, especially recycled plastic, by compression injection molding ( figure 2 )acquired. Using this process, known to those skilled in the art, makes it possible to obtain plates with a length (L) of approximately 1000-2000 mm, having a substantially planar or curved quadrilateral shape. The shape is perfectly straight in all dimensions of the board. In other words, regardless of the length (L) dimension, the plate structure obtained has no tendency to twist either in the vertical or in the horizontal plane.

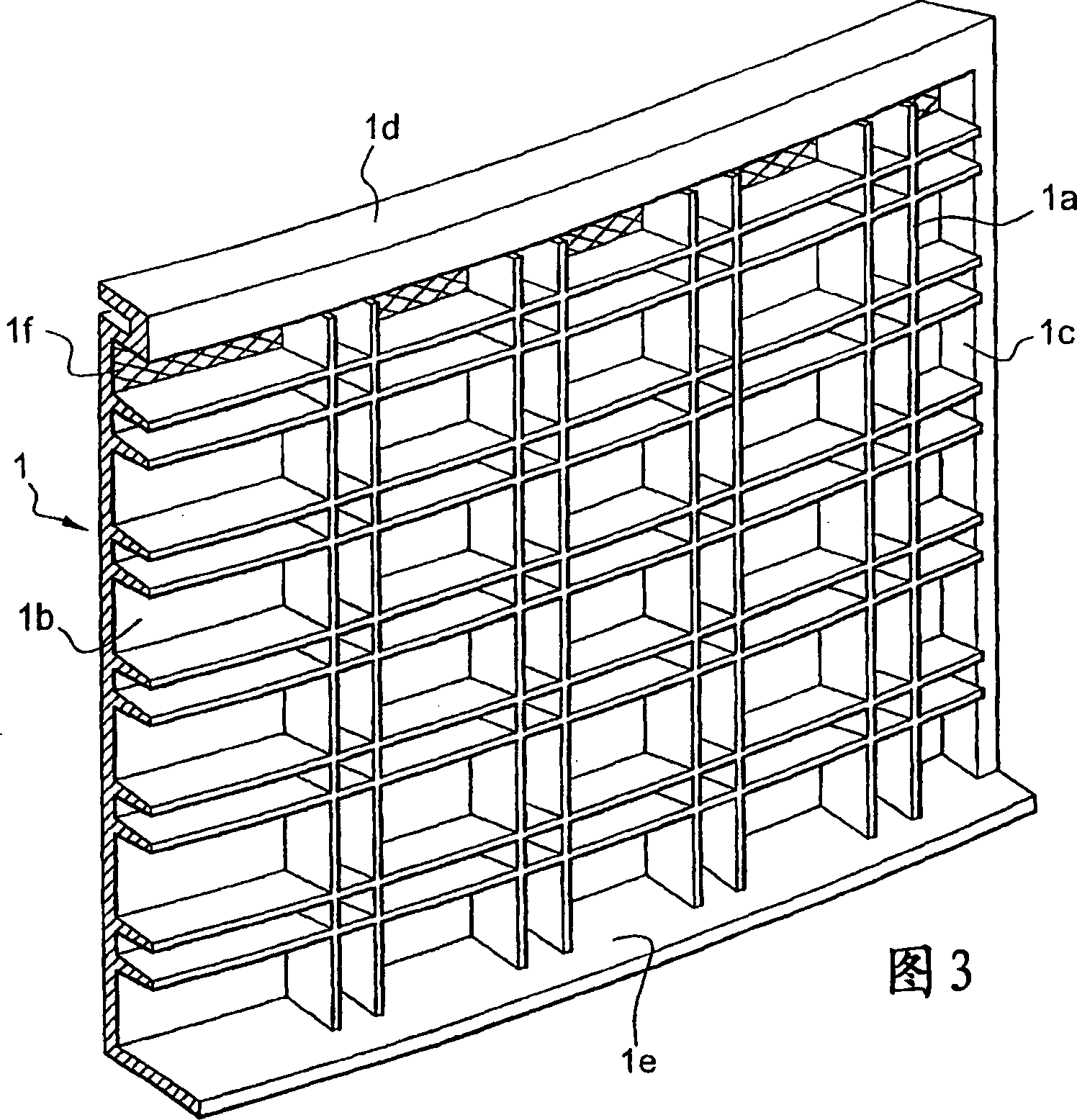

[0034] At least one face of the plate (1), ie the outer face, has a number of stiffeners (1a). These ribs (1a) are formed in vertical direction and / or horizontal direction. The plate (1) has on its ribbed side a square assembly and stiffener frame consisting of two vertical flanges (1b) and (1c) and two horizontal flanges (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com