A waste incineration flue gas online analysis system

A technology of waste incineration and analysis system, applied in sampling devices, preparation of samples for testing, etc., can solve the problems of low temperature, affecting detection accuracy, small component measurement values, etc., to reduce the number of joints, reduce equipment maintenance costs, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

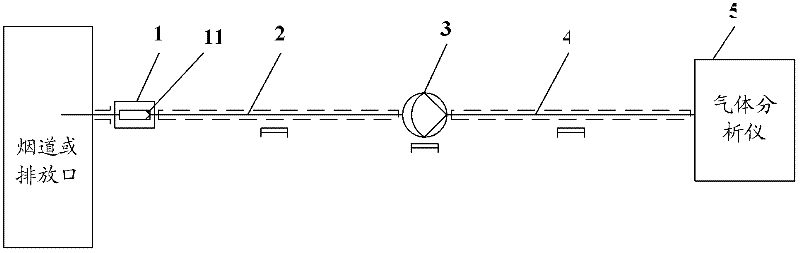

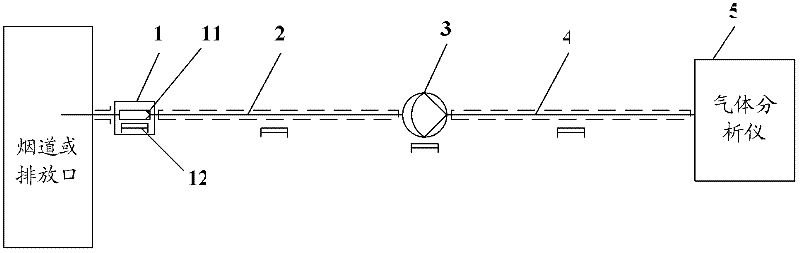

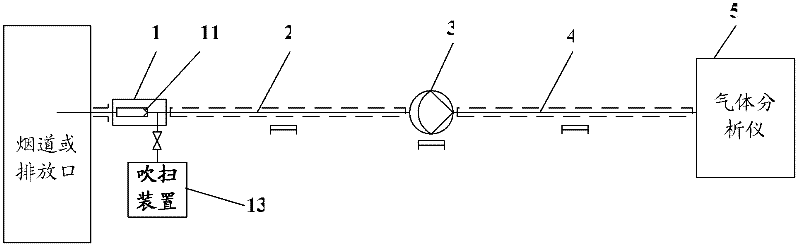

[0021] This embodiment provides an on-line analysis system for waste incineration flue gas, such as figure 1 As shown, the waste incineration flue gas online analysis system sequentially includes a sampling probe 1 , an external heating sampling line 2 , a sampling pump 3 , an internal heating sampling line 4 and a gas analyzer 5 along the direction of sample gas transmission.

[0022] The sampling probe 1 contains a sample gas filter 11 that can remove dust in the sample gas. The sample gas filter 11 can block particles with a particle size greater than or equal to 2 μm and prevent large particles from entering the external heating sampling pipeline 2 . The sampling pump 3 is accompanied by a heater,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com