Heavy-load SCARA (selective compliance assembly robot arm) transfer robot

A technology for handling robots and large loads, applied in the directions of manipulators, program-controlled manipulators, joints, etc., can solve the problems such as the SCARA robot's load capacity cannot reach large loads, the manufacturing cost of five-axis six-axis robots is high, and the structure of kinematic joints is complex. Achieve the effect of compact structure, few parts and multiple transmissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

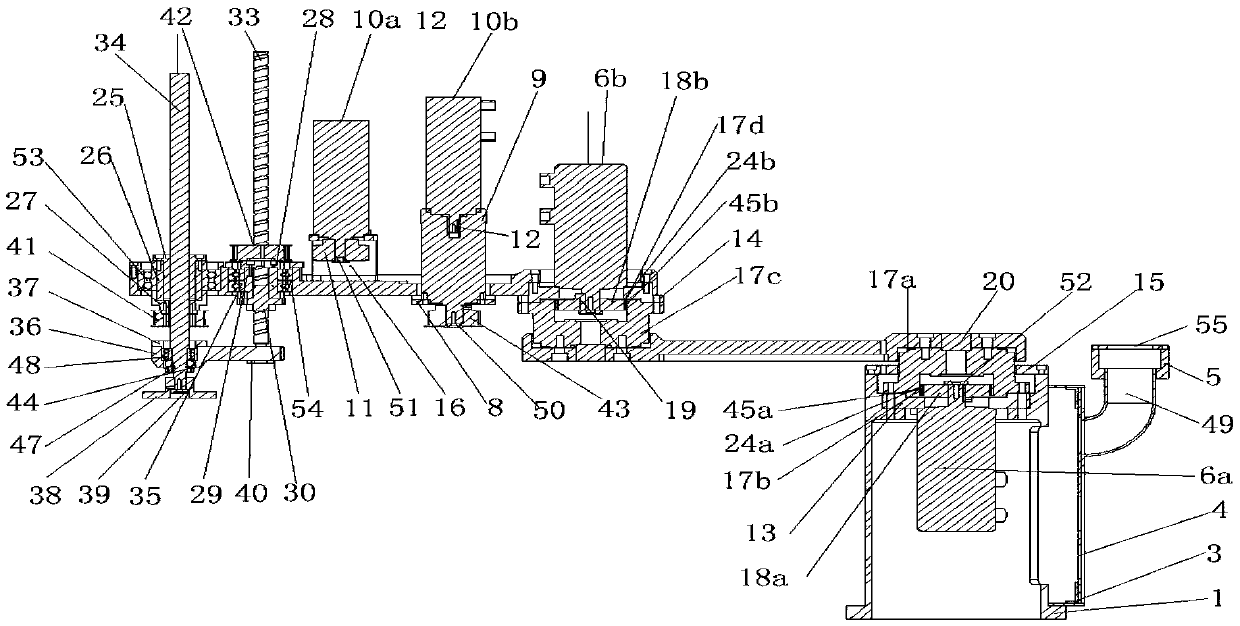

[0020] The present invention will be further described below in conjunction with accompanying drawing.

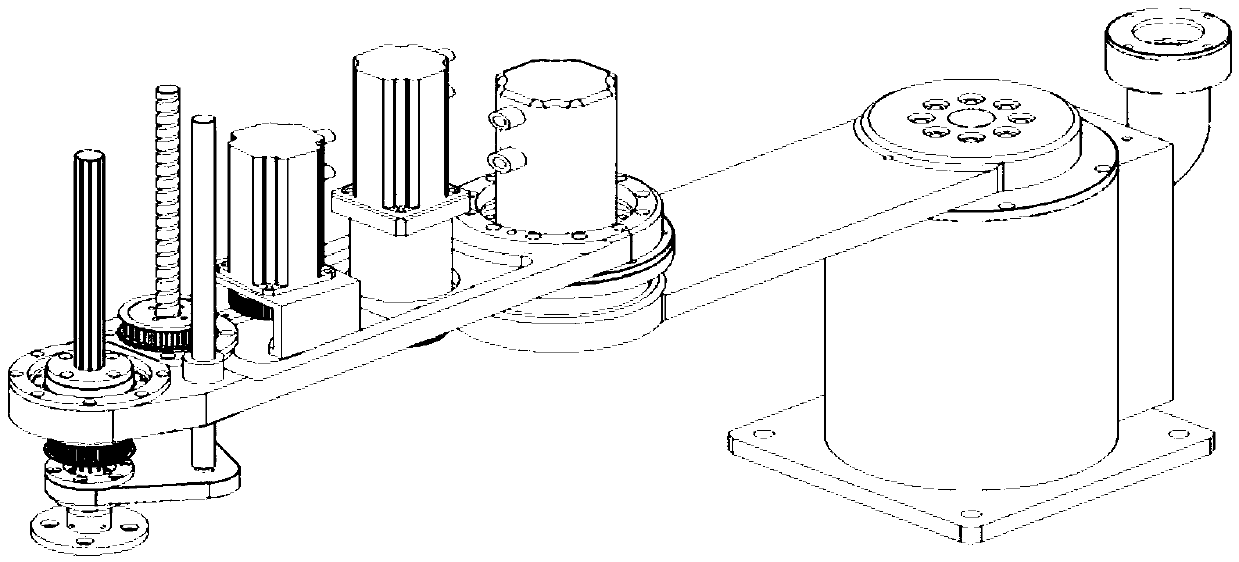

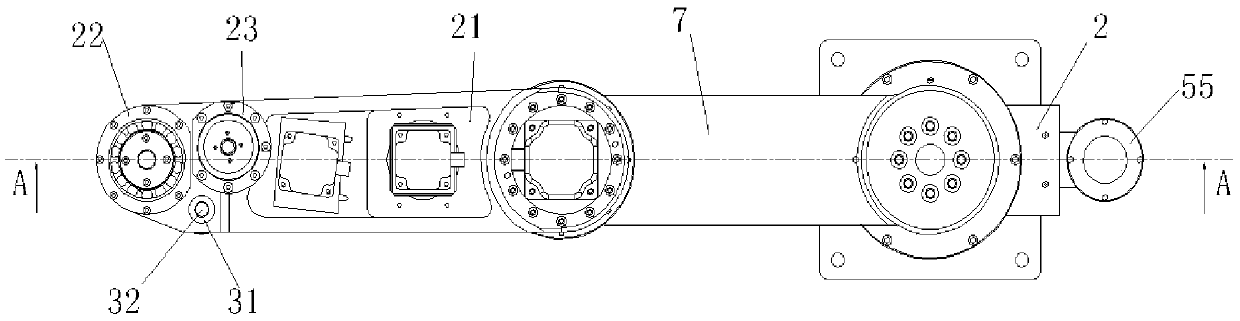

[0021] The robot of the present invention includes a frame, a first revolving joint, a second revolving joint and a wrist mechanism.

[0022] The frame includes a machine base 1, a fixed frame 3, a wiring board 4, a bend cover 5, a base cover 15, a bend 49 and a bend cover 55. Its structure is: the terminal board 4 is welded to the machine base 1, the fixing frame 3 is fixed on the terminal board 4 by bolts, the bend 49 is fixed on the machine base 1 by bolts, and the bend cover 5 is fixed on the bend through set screws. 49, the bend-through cover 5 and the bend-through cover plate 55 are fixedly connected by bolts.

[0023]The transmission of the boom rotary joint (the first rotary joint) is as follows: the first servo motor → the first harmonic reducer → the boom. The first rotary joint includes a first harmonic reducer, a first servo motor 6a, a boom 7, a boom steel wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com