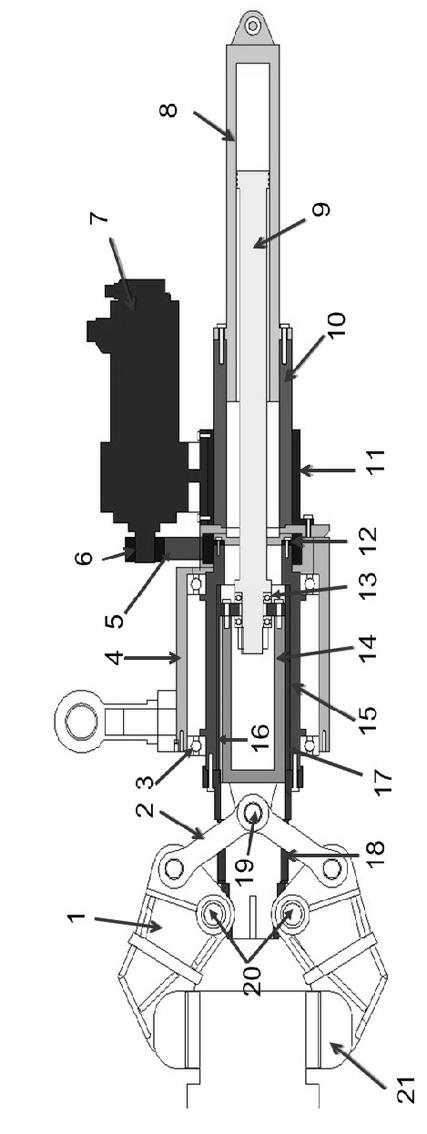

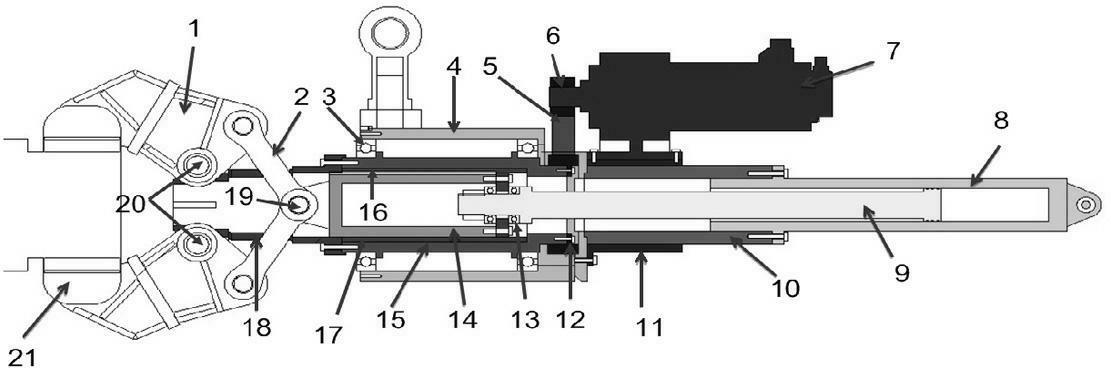

Claw rod mechanism of forging manipulator

A rod mechanism and machine pliers technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the fatigue failure of the pliers rod, large moment of inertia of the rotating part, poor dynamic performance, etc. problem, to achieve the effect of reducing the moment of inertia, good dynamic performance and high structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] This embodiment is a specific application example of the present invention, and its structure is as follows figure 1 Shown:

[0016] A forging manipulator involved in the present invention is mainly composed of a jaw clamping mechanism and a pincer arm rotating mechanism; wherein, the jaw clamping mechanism consists of a pincer arm 1, a connecting rod 2, a hydraulic piston cylinder 8, a piston rod 9, Thrust bearing A 12, thrust bearing B 13, connector 14, pliers case B 18, pin A 19, pin B 20, and jaw 21 are formed, and the pliers arm 1 is respectively hinged to the connector 14 and the pliers through pin A 19 and pin B 20. Shell B 18, thrust bearing A 12 and thrust bearing B 13 are installed at the end of the piston rod 9 and connected with the connecting piece 14; when the clamp rod mechanism of the forging operation machine performs clamping operation, the hydraulic piston cylinder 8 rodless chamber enters the hydraulic pressure oil, push the piston rod 9 to move for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com