Planet roller screw electric cylinder

A technology of planetary rollers and electric cylinders, applied in transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as low precision and low power of electric cylinders, to eliminate influence, ensure transmission accuracy, and facilitate modules The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

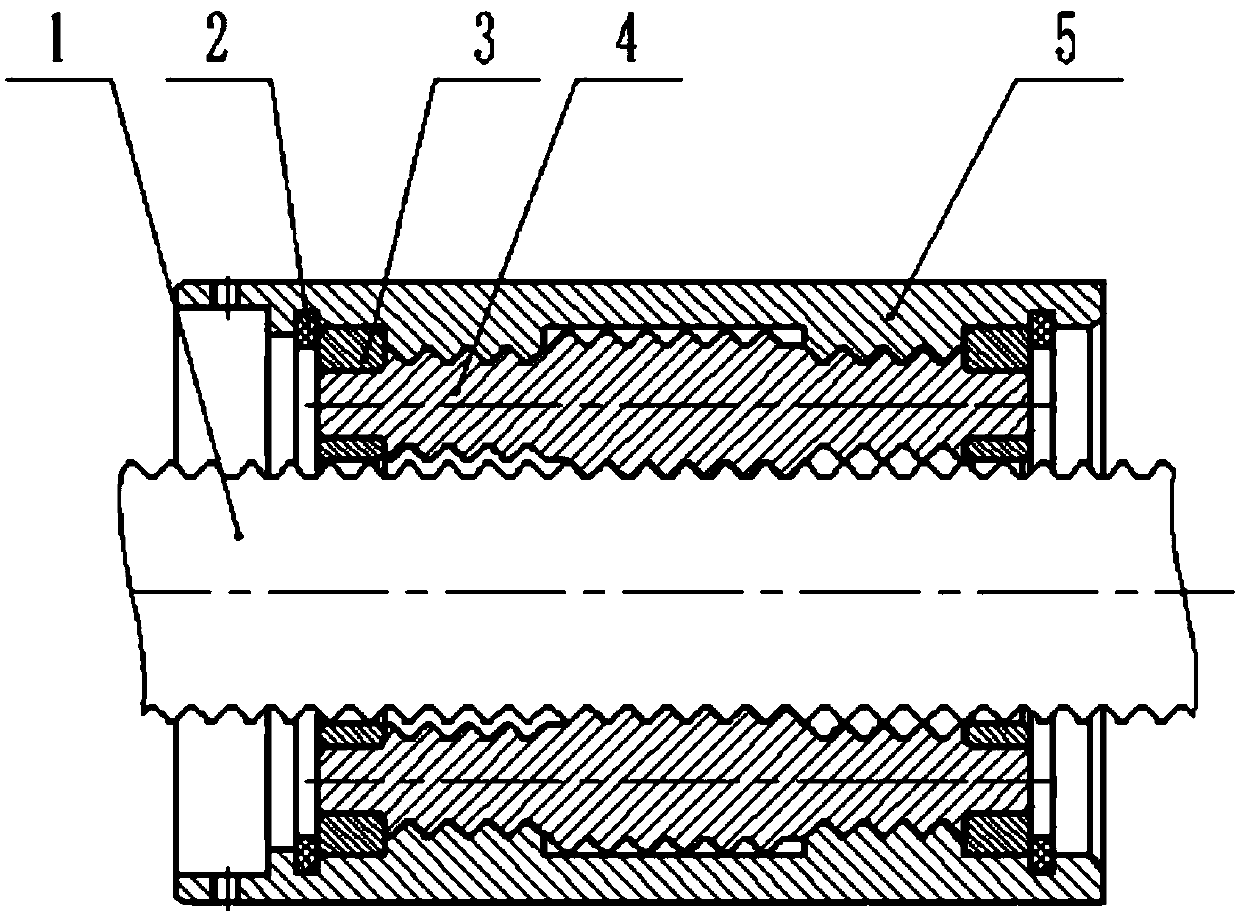

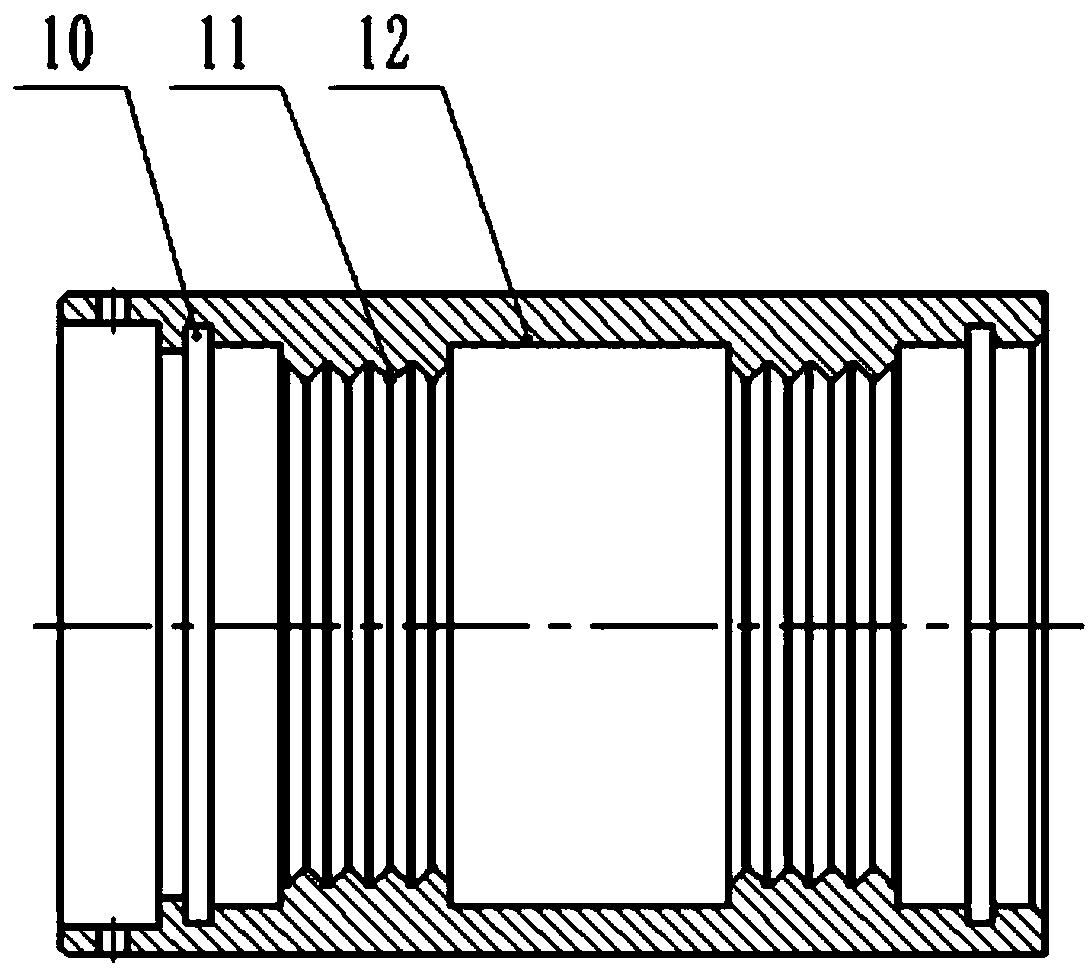

[0056] Such as Figure 1-Figure 4As shown, this embodiment discloses a planetary roller screw electric cylinder. The planetary roller screw electric cylinder includes a motor 22 , a cylinder body 17 , a power tube 13 and a planetary roller screw auxiliary transmission mechanism.

[0057] The motor 22 outputs power to the lead screw, and the power tube 13 is fixedly connected to the nut 5 through a set screw 18 . The planetary roller screw pair transmission mechanism is arranged in the cylinder body 17 , and the power tube 13 protrudes from the cylinder body 17 .

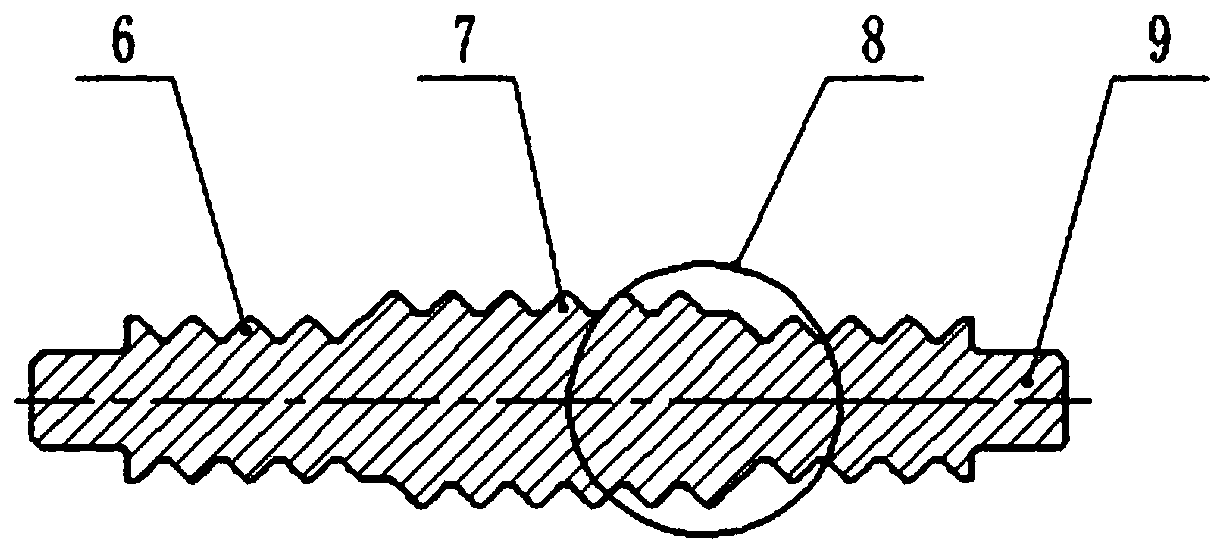

[0058] Such as Figure 1-Figure 3 As shown, the planetary roller screw auxiliary transmission mechanism includes a nut 5 , a lead screw 1 and a planetary roller 4 .

[0059] Such as figure 1 As shown, the nut 5 is sleeved with the outer side of the lead screw 1 at intervals. The planetary rollers 4 are distributed between the nut 5 and the screw 1 along the circumferential direction of the screw 1 .

[0060] The...

Embodiment 2

[0102] The structures and principles of this embodiment are the same as those of Embodiment 1 except for the connection mode of the motor, so details will not be repeated here.

[0103] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is a linear planetary roller screw electric cylinder structure. In this embodiment, the lead screw 1 and the motor 22 are connected through a coupling 25, and the linear electric cylinder has a compact structure.

[0104] In practical application, the linear electric cylinder of this embodiment and the reflex electric cylinder of Embodiment 1 can be selected according to different installation environments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com