Novel harmonic speed reducer of wave generator

A technology of harmonic reducer and wave generator, which is applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problem of the small number of meshing teeth, the lack of detailed expression of the cam shape curve of the wave generator, and the bottom of the tooth of the flexible wheel. Large force and other problems, to achieve reasonable structure, reduce force, improve the effect of force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

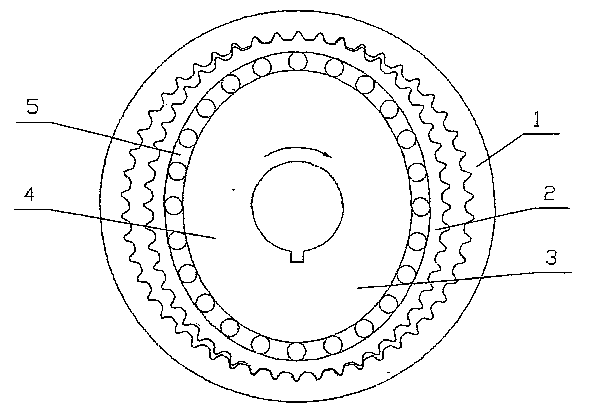

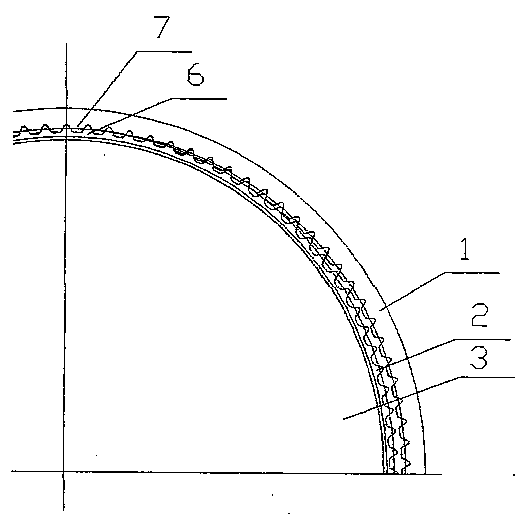

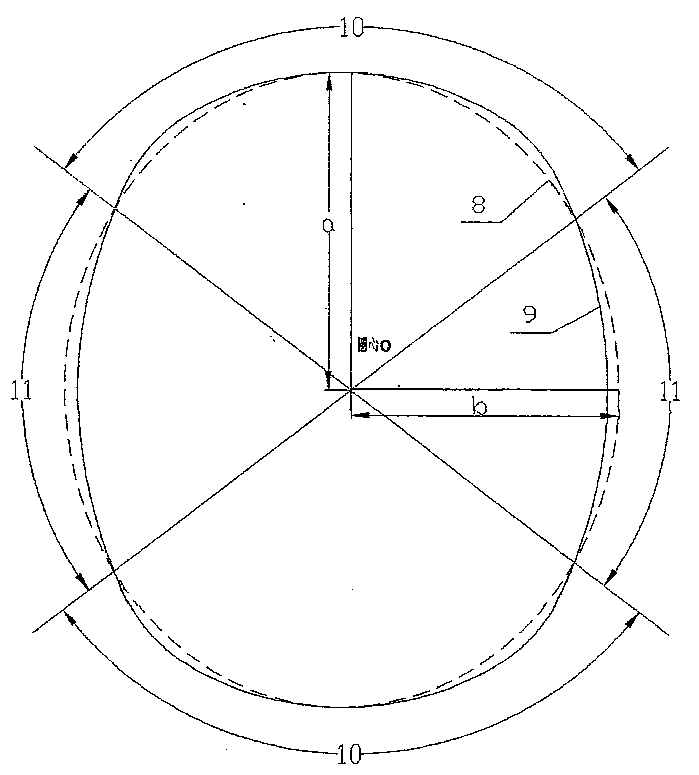

[0039] A harmonic reducer of a new type of wave generator, comprising an annular rigid wheel 1, the inner surface of the annular rigid wheel is provided with rigid internal teeth 7, and a wave generator 3 is arranged inside the annular rigid wheel; the wave generator The generator is composed of a rigid cam 4 with an elliptical profile and a flexible bearing 5 embedded in the outer ring of the rigid cam; a flexible wheel 2 is set on the outer bearing ring of the wave generator, and the outer surface of the flexible wheel is set to match the inner ring of the circular rigid wheel. The outer teeth 5 with matching teeth; the flexible wheel and the ring-shaped rigid gear are coaxially arranged; the wave generator is driven by a motor as the rotational driving source; the expression of the cam shape curve of the wave generator is:

[0040] R ( θ ) = ( a + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com