Filter speed reducer

A technology for reducers and external gears, which is applied in the direction of transmission devices, gear transmission devices, belts/chains/gears, etc. It can solve the problems of increasing the vibration and noise of the transmission mechanism, low torsional stiffness of elastic elements, and small torque, etc., to achieve Enhance the bearing capacity and anti-seismic ability, ensure the transmission accuracy and bearing capacity, and prevent the effects of nonlinear coupling vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

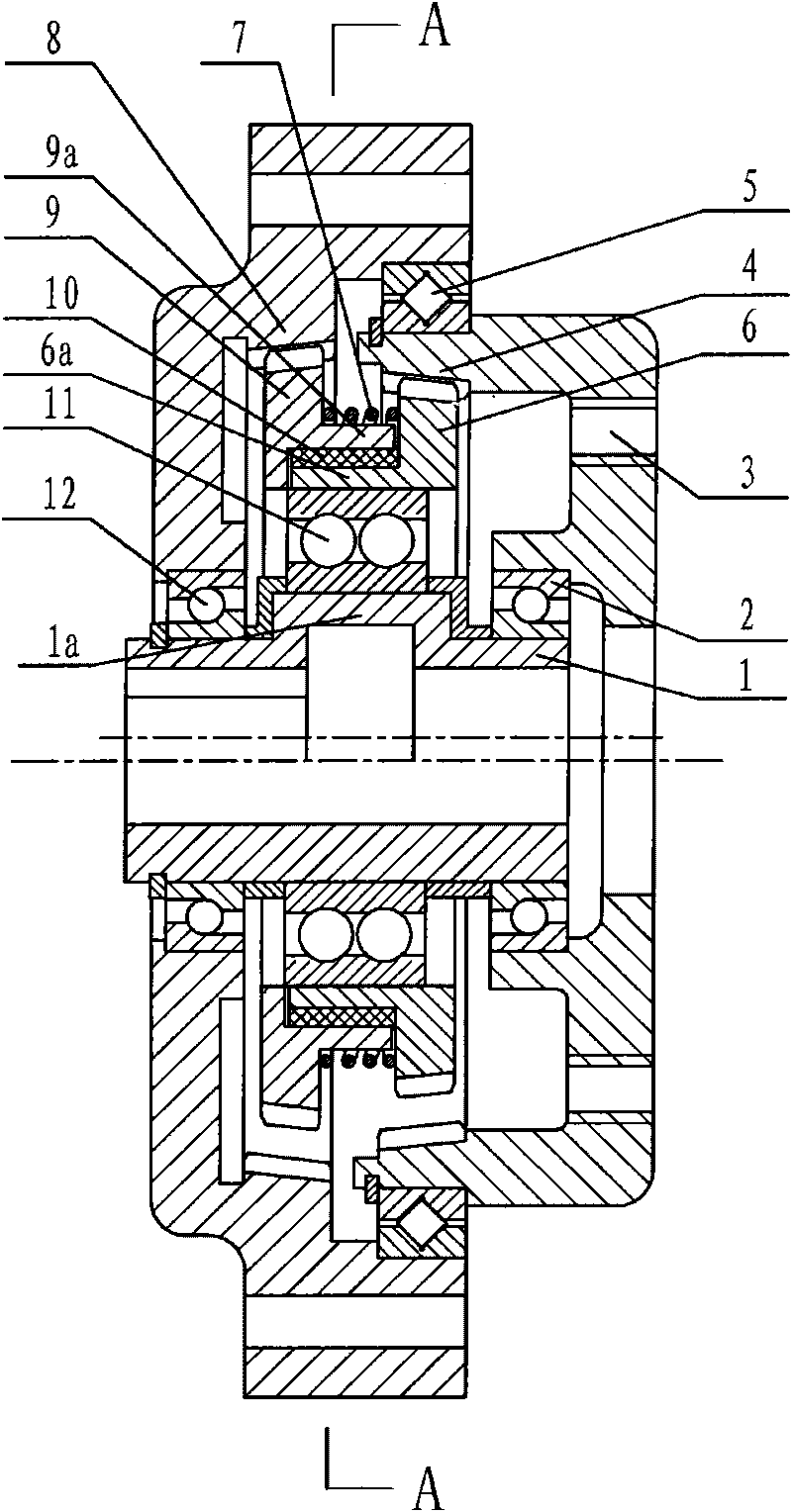

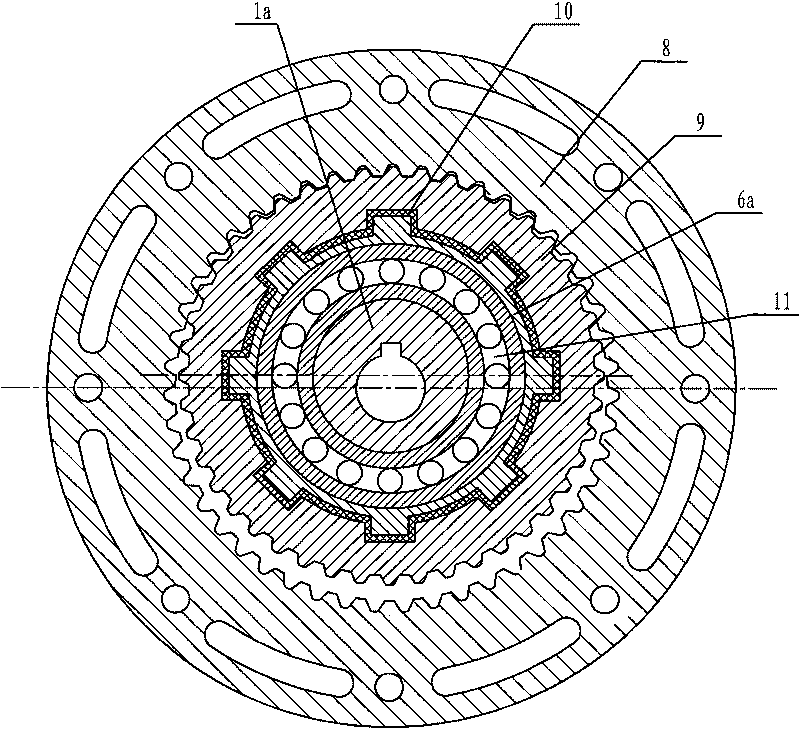

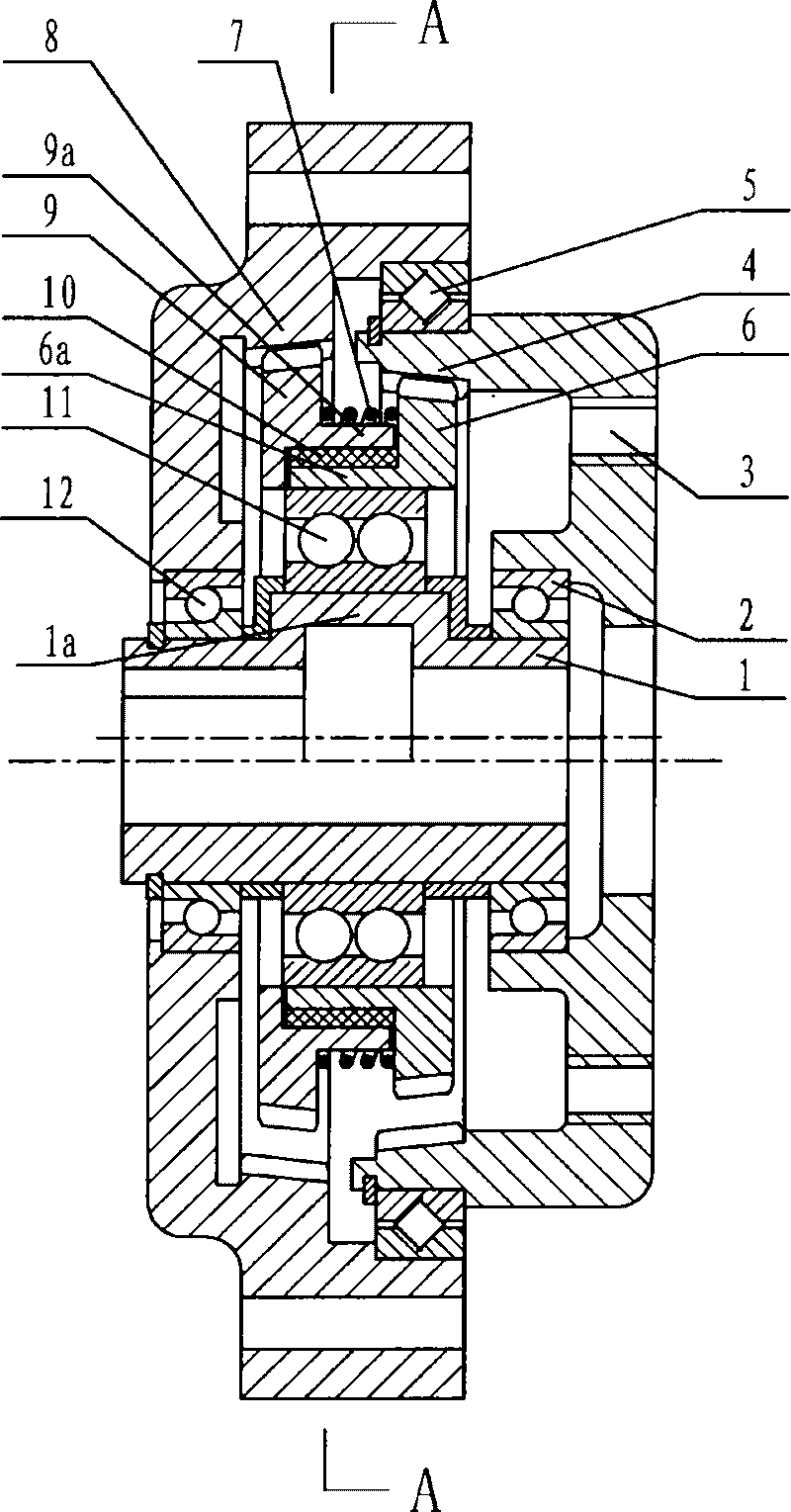

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A schematic diagram along the direction of A-A, as shown in the figure: the filter reducer of this embodiment includes a power input eccentric shaft 1, a split type double external gear, a fixed internal gear 8 and a power output internal gear 4, and the split type double external gear The gear rotates and fits on the eccentric shaft section 1a of the power input eccentric shaft 1. As shown in the figure, it is sleeved on the eccentric shaft section 1a through a rolling bearing 11; the split double external gear includes an external gear I9 and an external gear II6 arranged side by side. The outer gear I9 and the outer gear II6 are driven and matched in the circumferential direction through splines, and the splines of the outer gear I9 and the splines of the outer gear II6 are located on both sides of the key teeth to set meshing gaps, and the meshing gaps are tightly filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com