Wheel track stepless regulation type omnibearing mobile platform truck chassis

A technology of all-round movement and stepless adjustment, which is applied in vehicle maintenance, vehicle reloading, vehicle parts, etc., can solve the problems of non-adjustable, unable to adapt to road conditions and load size, etc., to improve carrying capacity, improve motion synchronization, The effect of ensuring transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

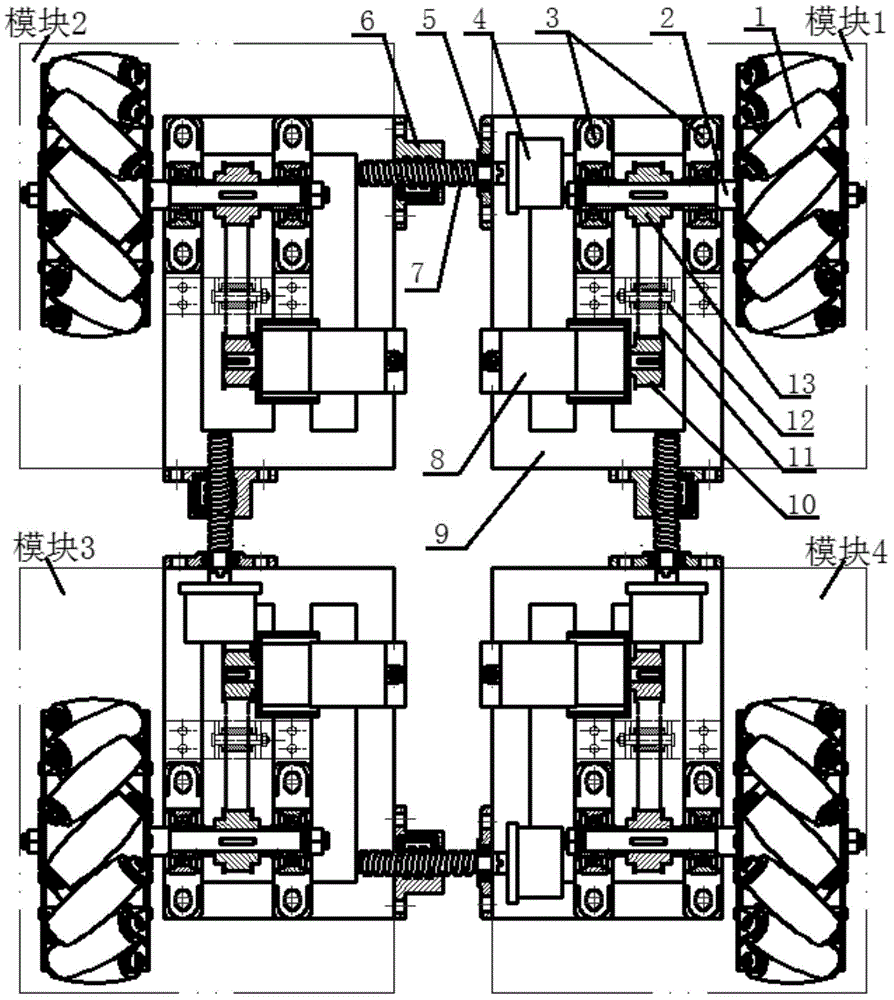

[0019] Such as figure 1 As shown, the chassis of an all-round mobile platform vehicle with stepless wheelbase adjustment provided by the present invention adopts a modular design concept and includes four modules. Among them, the structure of module 1 and module 2 is symmetrical, the structure of module 3 and module 4 is symmetrical, the structure of module 3 is completely consistent with that of module 1, and the structure of module 4 is completely consistent with that of module 2. The modular design is convenient for mass production and processing. It is not necessary to produce the entire platform chassis. It only needs to produce modules 1 and 2 in batches, and then connect the four modules through ball screws to form a platform chassis.

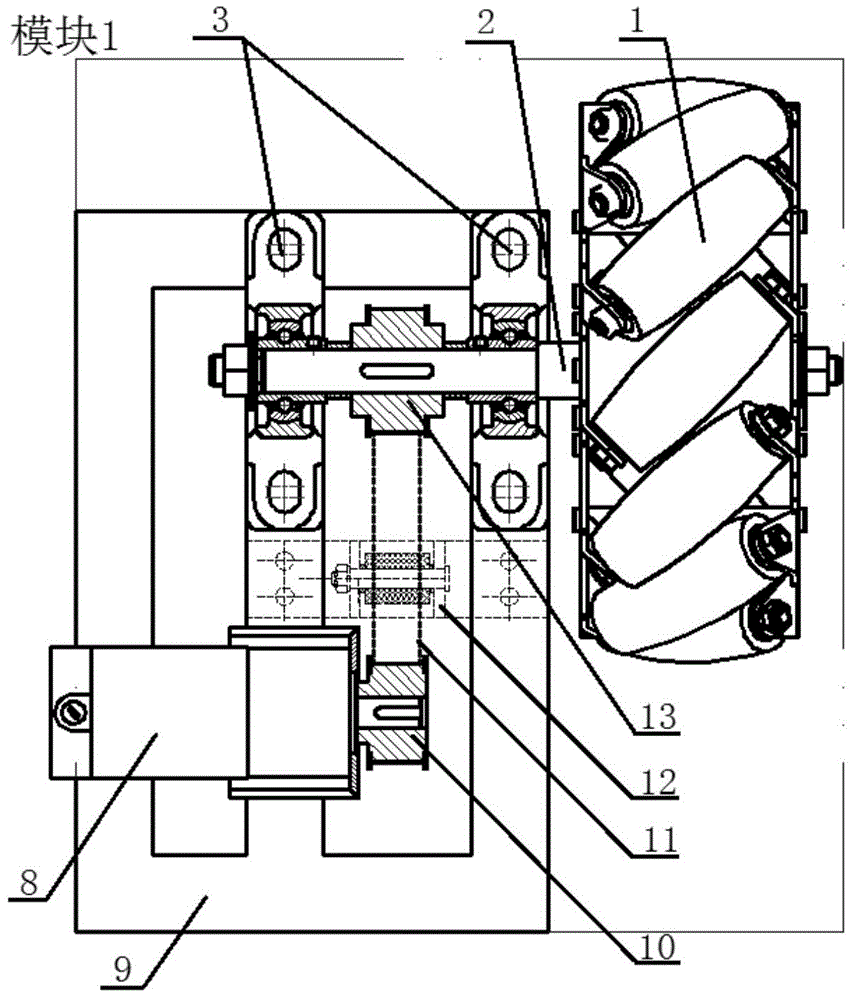

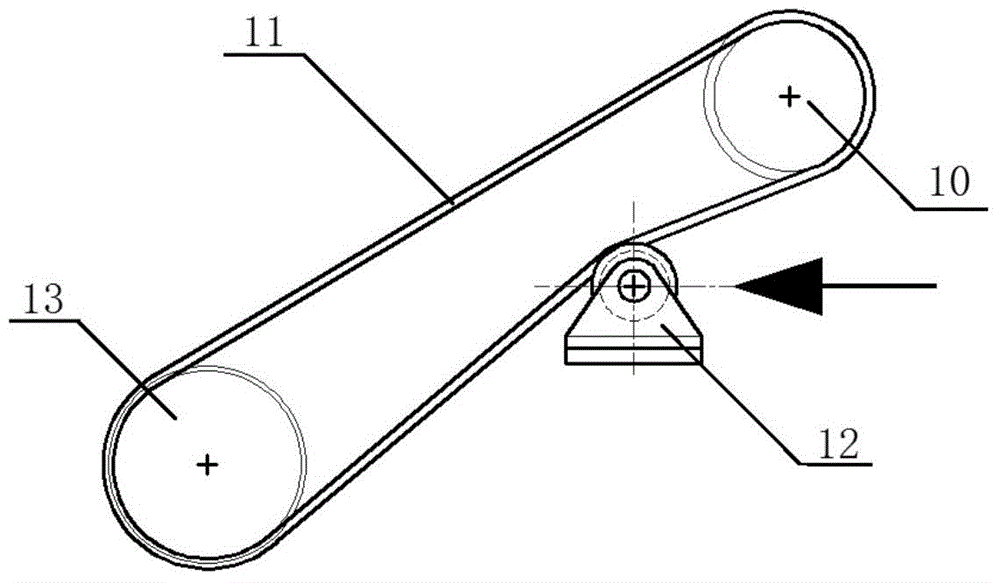

[0020] Such as figure 1 and figure 2 As shown, module 1 includes Mecanum omnidirectional wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com