Diamond grinding pad and its preparation process

A preparation process and diamond technology, applied in the field of grinding pads, can solve the problems of scratched surface quality, scratches, and good smoothness, and achieve the effects of good stability of grinding efficiency, improved grinding efficiency and low surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention also discloses a preparation process of a diamond grinding pad, comprising the following steps:

[0030] (1) Preparation of diamond group abrasives: Firstly, single-grain diamond, adhesive and filler are mixed and dispersed uniformly; then spherical aggregates are obtained by spray drying, fluidized bed or sol-gel method; then the spherical aggregates are solidified And sieve to obtain diamond group abrasives with suitable particle size. The curing method is light curing or thermal curing; the adhesive used in the preparation of diamond group abrasives is inorganic or organic adhesive, or ceramic adhesive, metal bond, UV glue or epoxy resin, and all fillers are calcium carbonate, limestone, One or more of wollastonite and silica.

[0031] (2) Preparation of abrasive layer: Mix and disperse the diamond group abrasive prepared in step (1) with adhesive and filler evenly; after fully dispersed, vacuumize to eliminate air bubbles to obtain the required slurry...

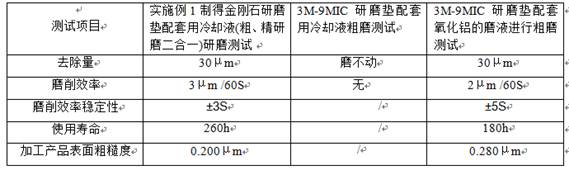

Embodiment 1

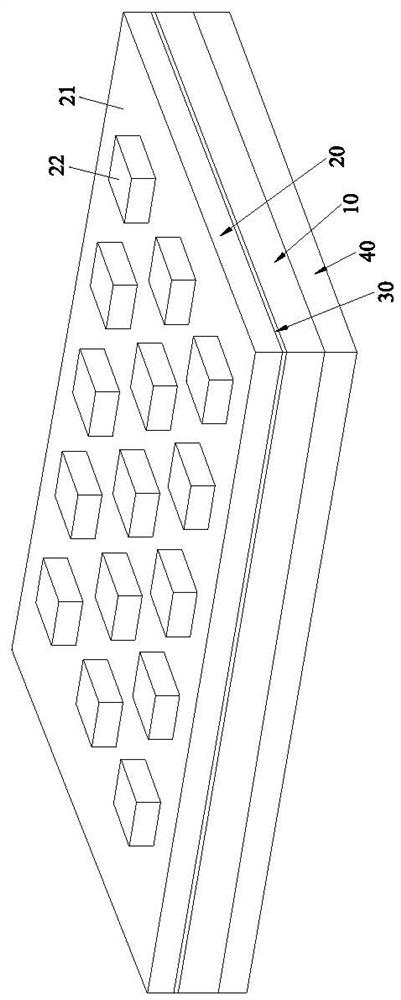

[0035] A specific structure of a diamond grinding pad, including a substrate 10 and an abrasive layer 20 arranged on the surface of the substrate 10, the abrasive layer 20 includes the following mass percentage raw materials: 8% diamond group abrasive, 72% adhesive, and the remainder is filler ; Wherein the diamond group abrasive is formed by a single-grain diamond group.

[0036] The particle size of the diamond group abrasive is 50-80 μm. The single-grain diamond is single crystal diamond, which is treated with a surface modifier and acid-base, the adhesive is an inorganic adhesive, and the filler is calcium carbonate. And, the abrasive layer 20 is pasted and fixed on the surface of the substrate 10 through the adhesive layer 30 , and the bottom surface of the substrate 10 is covered with a back adhesive layer 40 for mounting and fixing with the outside.

[0037] The invention also discloses a preparation process of a diamond grinding pad, comprising the following steps:

...

Embodiment 2

[0045] A specific structure of a diamond grinding pad, including a substrate 10 and an abrasive layer 20 arranged on the surface of the substrate 10, the abrasive layer 20 includes the following mass percentage raw materials: 5% diamond group abrasive, 70% adhesive, and the remainder is filler ; Wherein the diamond group abrasive is formed by a single-grain diamond group.

[0046]The particle size of the diamond group abrasive is 50-80 μm. The single-grain diamond is single-crystal diamond, which is treated with a surface modifier and acid-base, the adhesive is an organic adhesive, and the filler is limestone. And, the abrasive layer 20 is pasted and fixed on the surface of the substrate 10 through the adhesive layer 30 , and the bottom surface of the substrate 10 is covered with a back adhesive layer 40 for mounting and fixing with the outside.

[0047] The invention also discloses a preparation process of a diamond grinding pad, comprising the following steps:

[0048] (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com