Functional cellulose-based porous material as well as preparation method and application thereof

A cellulose and functionalization technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of cumbersome modification, low modification efficiency, and long time consumption, and achieve the effect of safe preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

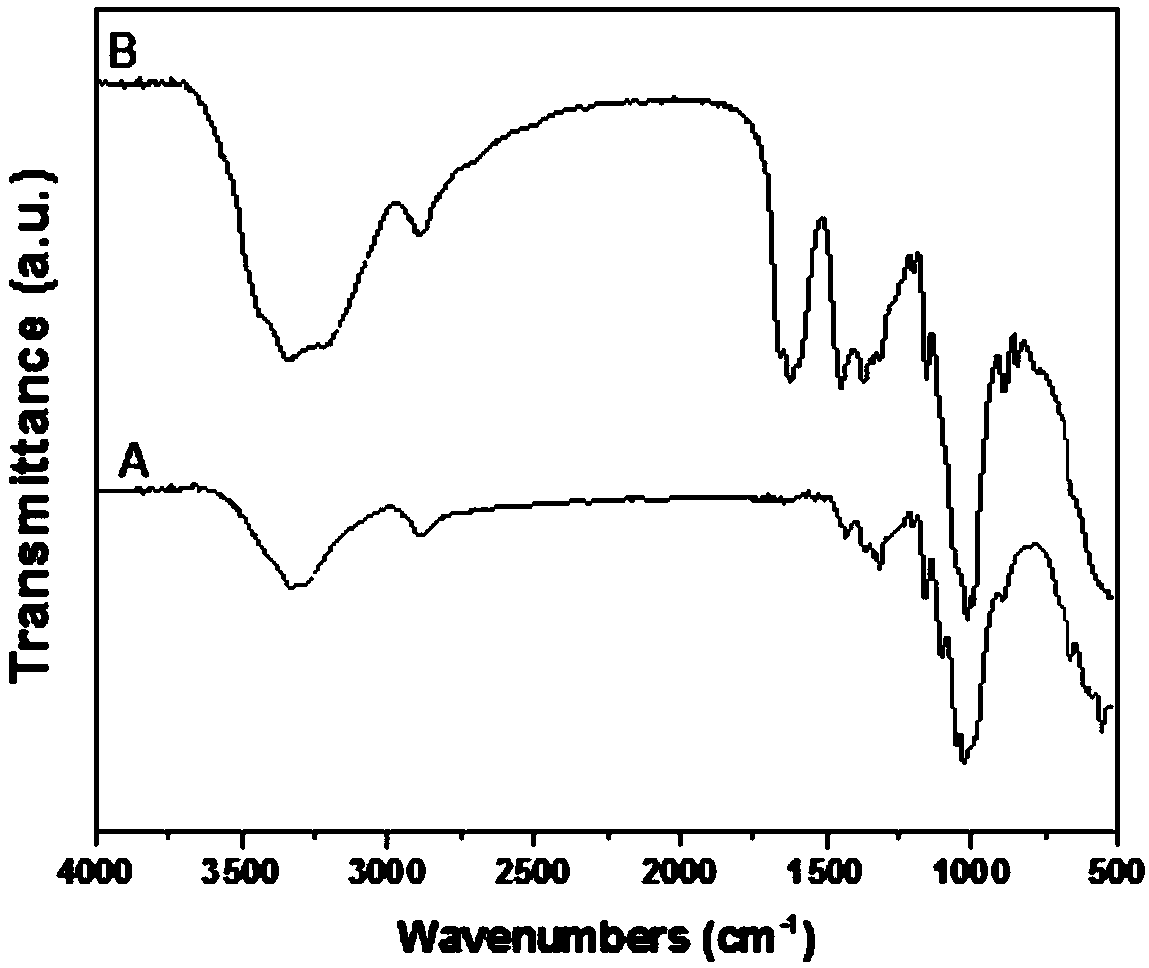

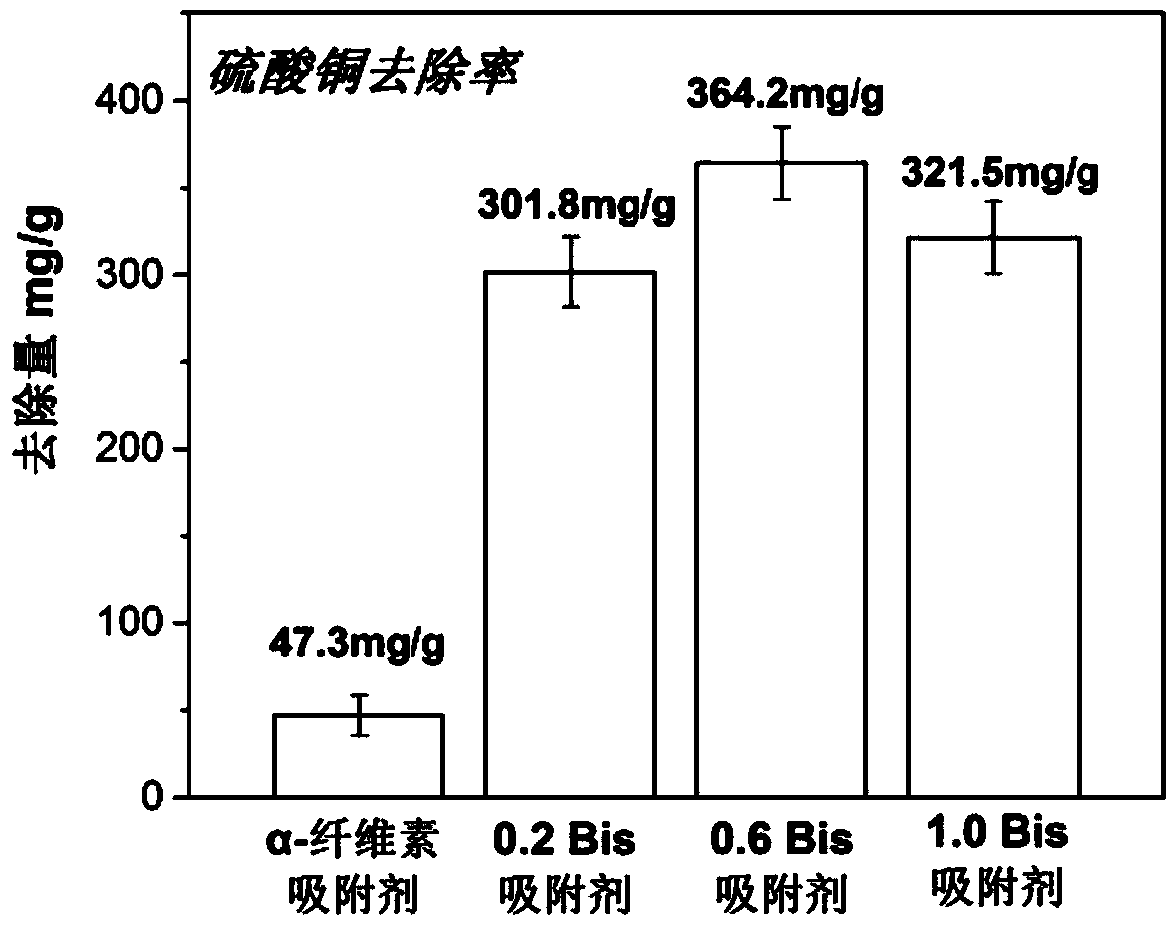

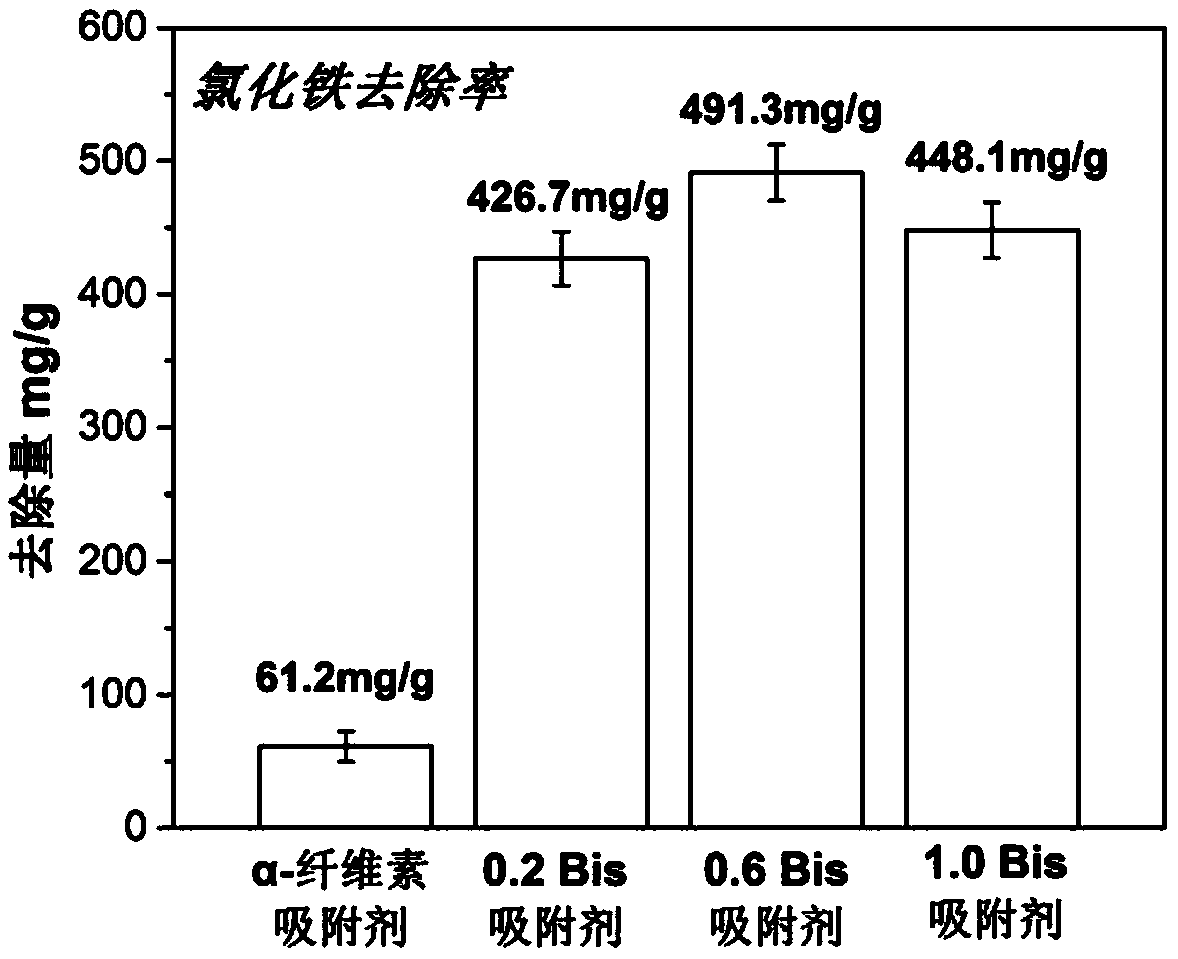

[0062] Weigh 5g of α-cellulose, 1g of N,N'-methylenebisacrylamide, and disperse them in a mixed aqueous solution of 245g of sodium hydroxide and urea (the mass ratio of sodium hydroxide, urea and water is 3:12:85) , Freeze at -12°C for 30 minutes, stir at room temperature for 5 minutes after freezing, let stand at room temperature for 2 hours, soak in pure water until neutral, and obtain 0.2Bisα-cellulose-based porous adsorption material, the Bisα-cellulose-based porous adsorption material BET specific surface area up to 472m 2 / g.

Embodiment 2

[0064] Weigh 5g α-cellulose, 3g N,N'-methylenebisacrylamide, and disperse in the mixed aqueous solution of 245g sodium hydroxide and urea (the mass ratio of sodium hydroxide, urea and water is 3:12:85) , Freeze at -12°C for 30 minutes, stir at room temperature for 5 minutes after freezing to obtain cellulose-based sol; stand at room temperature for 2 hours, soak in pure water until neutral, and obtain 0.6Bis α-cellulose porous adsorption material, the α-cellulose The BET specific surface area of the porous adsorption material can reach 456m 2 / g.

Embodiment 3

[0066] Take by weighing 5g α-cellulose part quality, 5g N, N'-methylenebisacrylamide, be dispersed in the mixed aqueous solution of the sodium hydroxide of 245g and urea (the mass ratio of sodium hydroxide, urea and water is 3:12: 85), frozen at -12°C for 30 minutes, stirred at room temperature for 5 minutes after freezing, to obtain cellulose-based sol; left at room temperature for 2 hours, soaked in pure water until neutral, and obtained 1.0 Bisα-cellulose porous adsorption material, the Bisα- The BET specific surface area of cellulose porous adsorption material can reach 437m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com