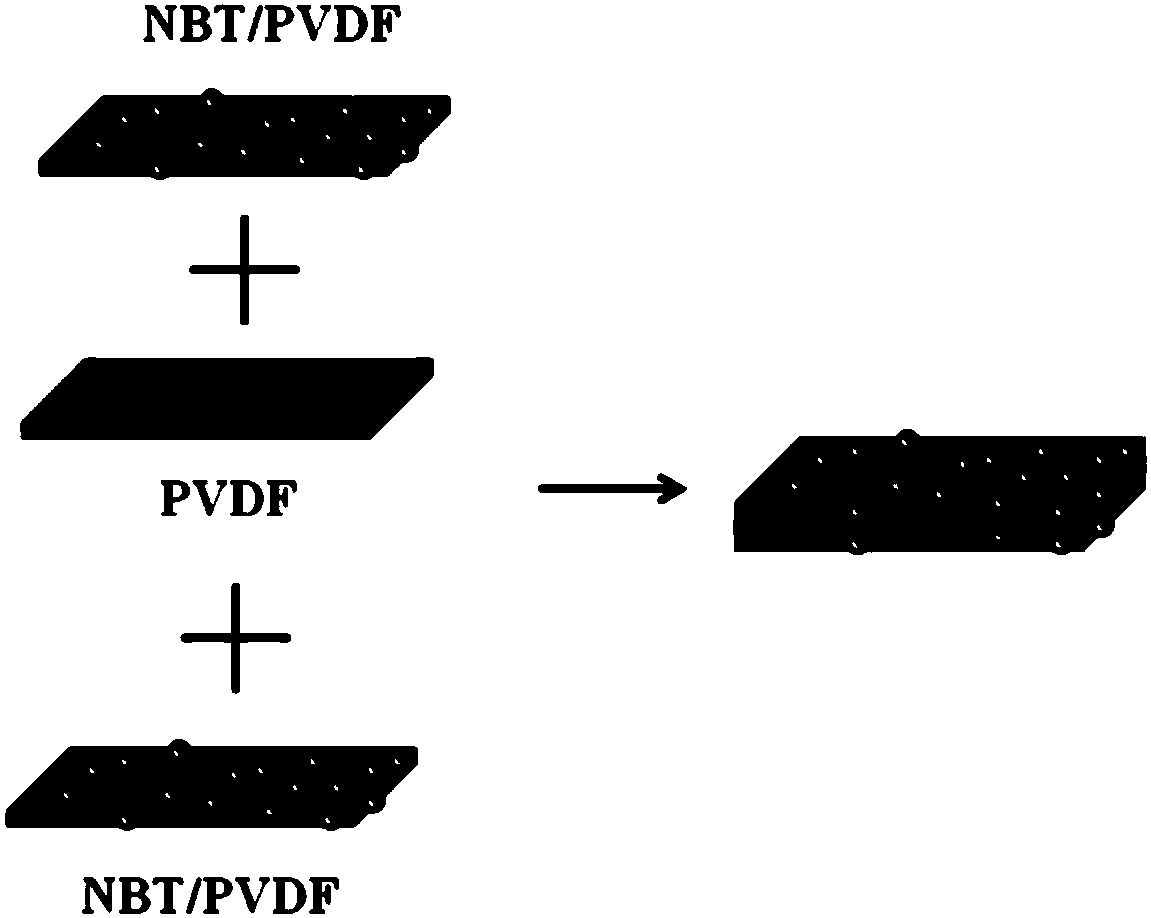

NBT/PVDF three-layer structured composite material for energy storage and preparation method thereof

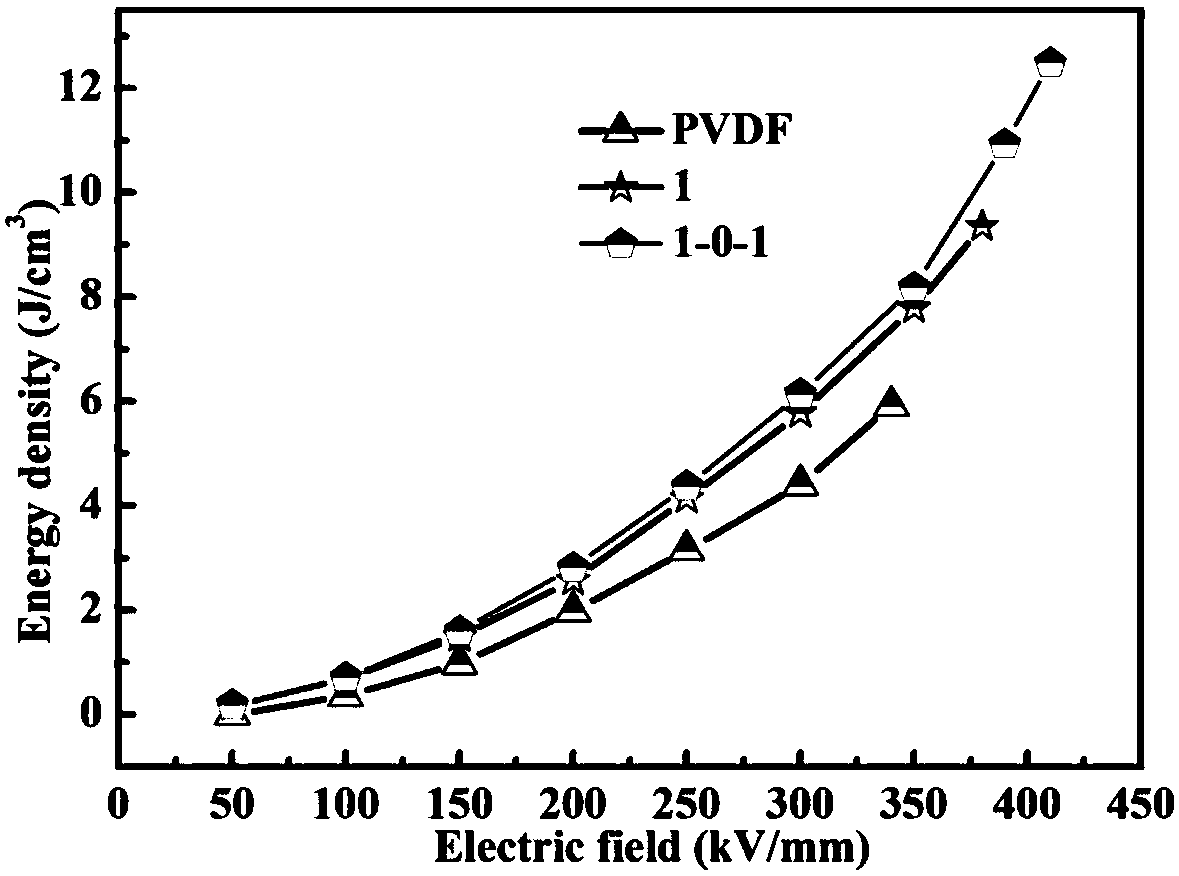

A technology of polyvinylidene fluoride and bismuth sodium titanate, which is applied in the direction of coating, etc., can solve the problems of polluting the environment, human health, toxic chemicals, and limiting energy storage density, and achieves safe and reliable preparation methods, simple process flow, and storage The effect that can improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method for bismuth sodium titanate / polyvinylidene fluoride composite material for energy storage, comprising the following steps,

[0034] (1) take sodium carbonate, bismuth oxide and titanium dioxide raw materials according to the molar ratio;

[0035] (2) Put zirconia balls, raw materials and deionized water together into the ball mill tank for ball milling; the mass ratio of zirconia balls, raw materials and deionized water is (2~5):1:1, and the ball milling time is 3~6h;

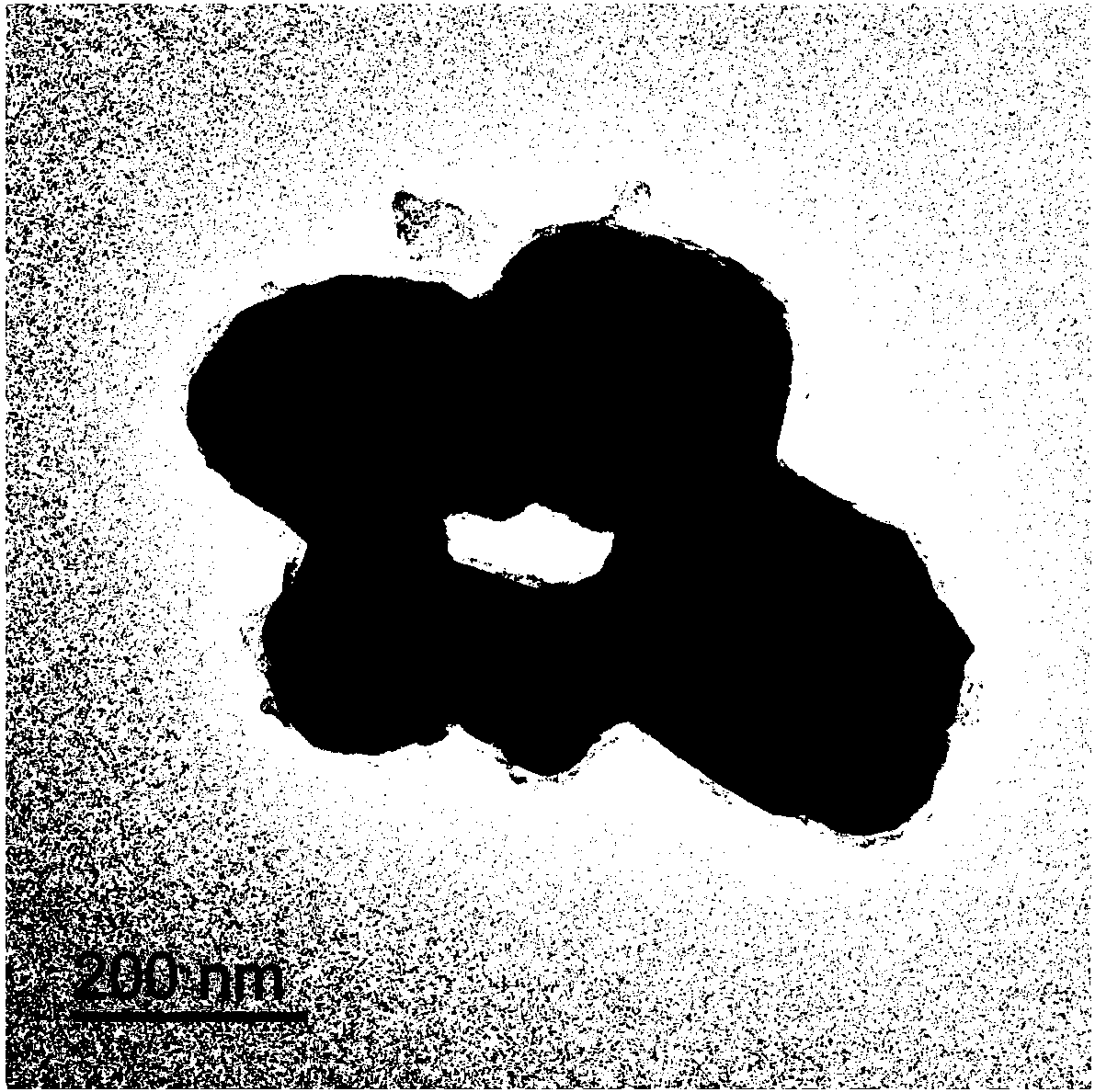

[0036] (3) Pour the mixed slurry after ball milling into a vessel, put it in an oven, dry it at 70°C-150°C for 8-12 hours, grind and sieve to obtain a powder, and put the obtained powder into an alumina crucible, Put it into a muffle furnace for pre-firing, the pre-firing temperature is 700-900°C, and the holding time is 3-7 hours, and then take out the crucible after the muffle furnace is naturally cooled to room temperature, and the sodium bismuth titanate particle powder is obtain...

example 1

[0047] A kind of preparation method of the sodium bismuth titanate / polyvinylidene fluoride composite material used for energy storage of the present invention comprises the following steps, (1) taking sodium carbonate, bismuth oxide and titanium dioxide as raw materials according to the molar ratio;

[0048] (2) According to the mass ratio of 5:1:1, weigh the zirconia balls, raw materials and deionized water and add them into the ball mill jar for ball milling for 4 hours;

[0049] (3) Pour the mixed slurry after ball milling into a container, put it in an oven, dry it at 80°C for 12 hours, and then grind and sieve it to obtain a powder, put the obtained powder into an alumina crucible, put it into a muffle In the furnace, pre-fire at 800 ° C, the holding time is 4 hours, and then take out the crucible after the muffle furnace is naturally cooled to room temperature, and the sodium bismuth titanate particle powder is obtained;

[0050] (4) Weigh the zirconia balls, the bismuth...

example 2

[0059] A kind of preparation method of the sodium bismuth titanate / polyvinylidene fluoride composite material used for energy storage of the present invention comprises the following steps, (1) taking sodium carbonate, bismuth oxide and titanium dioxide as raw materials according to the molar ratio;

[0060] (2) According to the mass ratio of 2:1:1, weigh zirconia balls, raw materials and deionized water and add them into the ball mill jar for ball milling for 5 hours;

[0061] (3) Pour the mixed slurry after ball milling into a container, put it in an oven, dry it at 70°C for 8 hours, and then grind and sieve it to obtain a powder, put the obtained powder into an alumina crucible, put it into a muffle Pre-fire in the furnace at 750°C for 3 hours, and then take out the crucible after the muffle furnace cools down to room temperature naturally, and obtain the sodium bismuth titanate particle powder;

[0062] (4) Weigh the zirconia balls respectively according to the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com