Width division cutter for glass fiber production

A glass fiber and sizing technology, applied in the field of sizing cutters for glass fiber production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

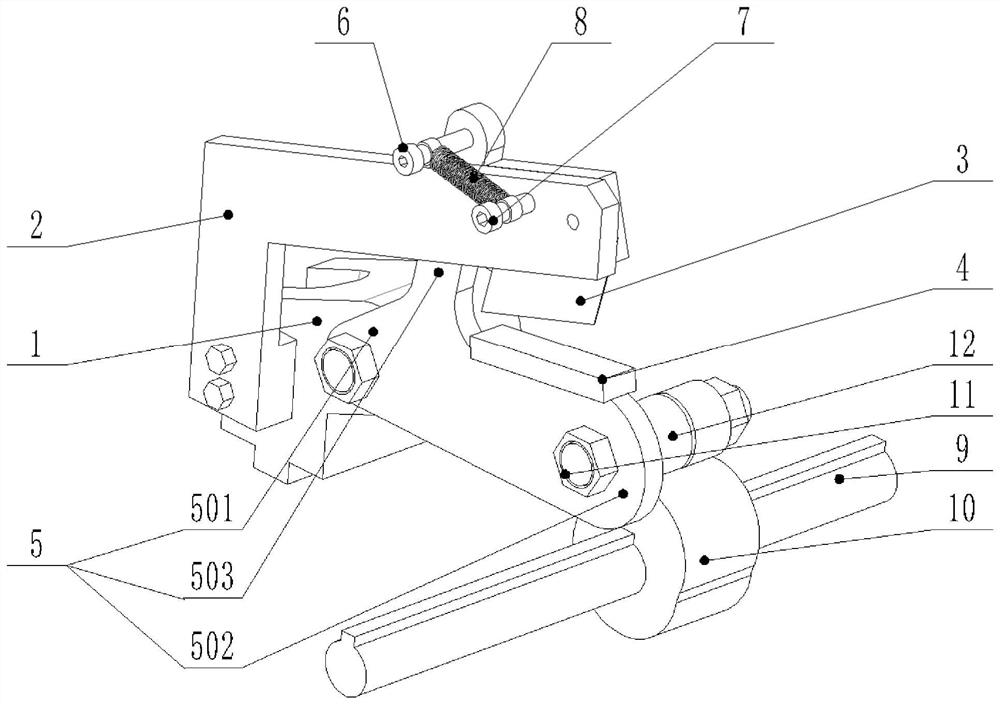

[0023] Such as figure 1 As shown, a framing cutter for glass fiber production includes a base 1, a knife holder 2, a blade 3, a pad 4, a fixing seat 5 and a pad driving mechanism; the knife holder 2 is fixedly arranged on the base 1; the blade 3 fixedly arranged on the knife rest 2; the spacer 4 is fixedly arranged on the fixed seat 5; the spacer 4 is arranged in conjunction with the blade 3; the fixed seat 5 is hinged on the base 1; the driving mechanism of the spacer is arranged under the fixed seat 5 for driving The spacer 4 on the fixed seat 5 is in intermittent contact with the blade 3 . The intermittent contact between the spacer 4 and the blade 3 is driven by the spacer driving mechanism arranged under the fixed seat 5 to complete the cutting and framing, which avoids the quality problem caused by the contamination of the cloth surface.

[0024] The tool holder 2 is arranged in an L shape as a whole, one end is fixedly arranged on the base 1, and the other end is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com