Preparation method of composite abrasive material

A composite abrasive and abrasive technology, applied in the field of abrasive manufacturing, can solve problems such as being difficult to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

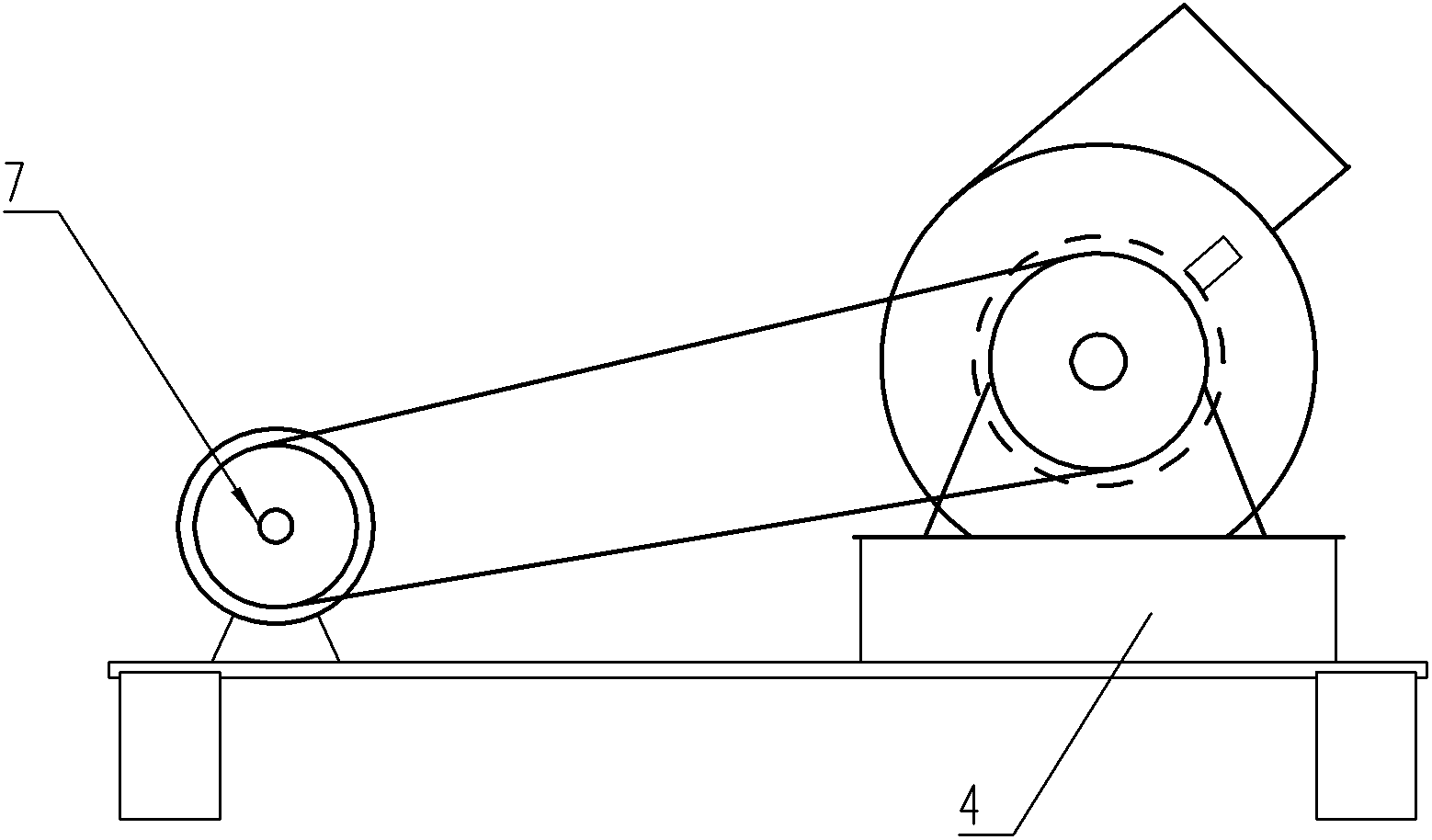

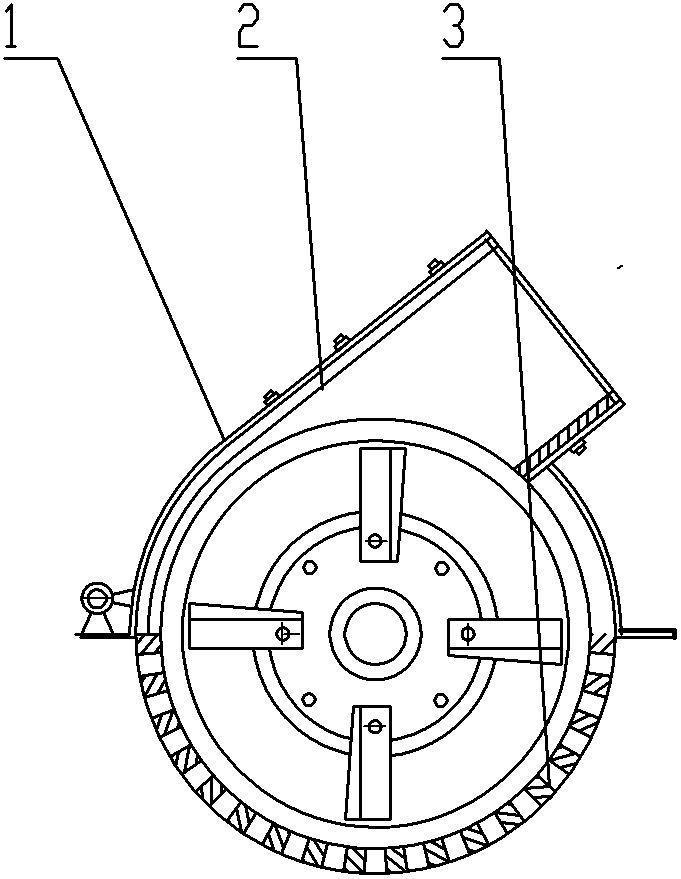

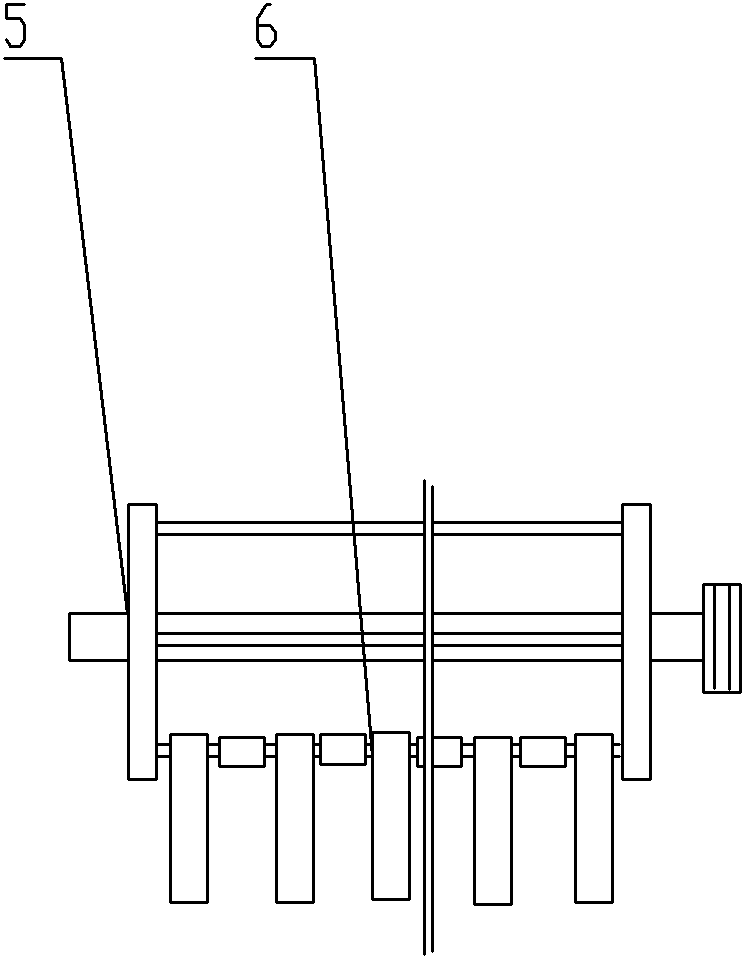

Image

Examples

Embodiment 1~9

[0033] Embodiments 1 to 9 are specific embodiments of the present invention, and Embodiment 7 is the best embodiment of the present invention.

[0034] Table 1 Embodiment 1~9 Composite abrasive components (by weight)

[0035]

[0036]

[0037] Wherein, the manufacturing method of embodiment 1~3 comprises the following steps:

[0038] a) Weigh 30# corundum, polyurethane elastic material, and flame retardant according to the ratio in Table 1, and put them into containers respectively, ready for use.

[0039] b) Add corundum, polyurethane elastic material and flame retardant according to the proportions in Table 1, into the mixing tank equipped with a stirrer, the blade speed in the mixing tank is 400-500r / min, rotate and stir, and suspend the corundum in the foaming Composite abrasive semi-finished products are made of polyurethane elastic material foam.

[0040] c) Put the finished composite abrasive semi-finished product into a box furnace or a pit furnace for curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com