Methods and systems for devolatilization of thermally produced liquids

A devolatilization and liquid technology, applied in liquid degassing, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

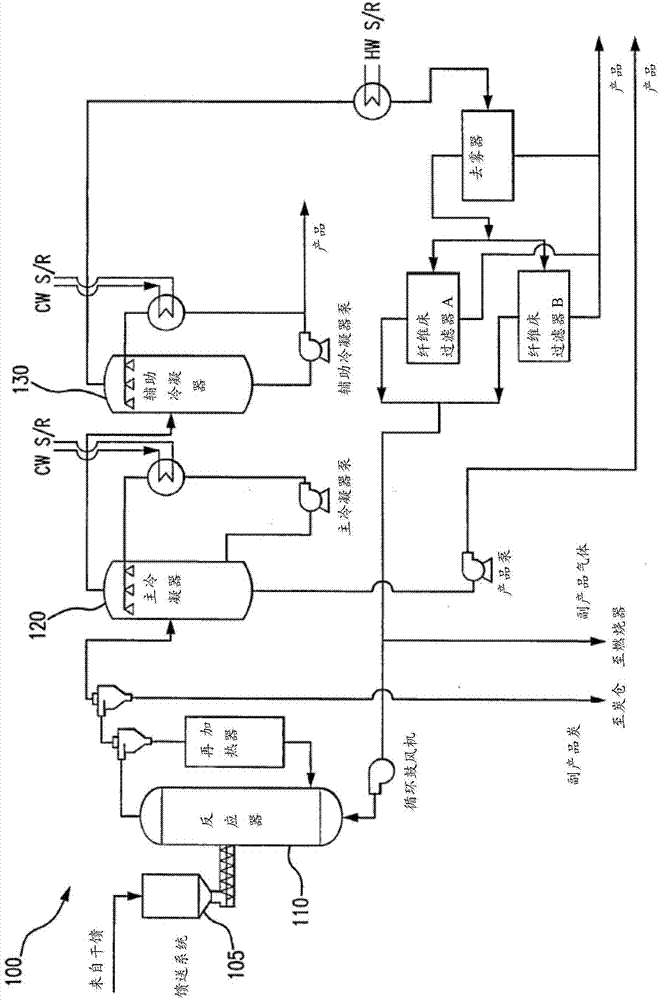

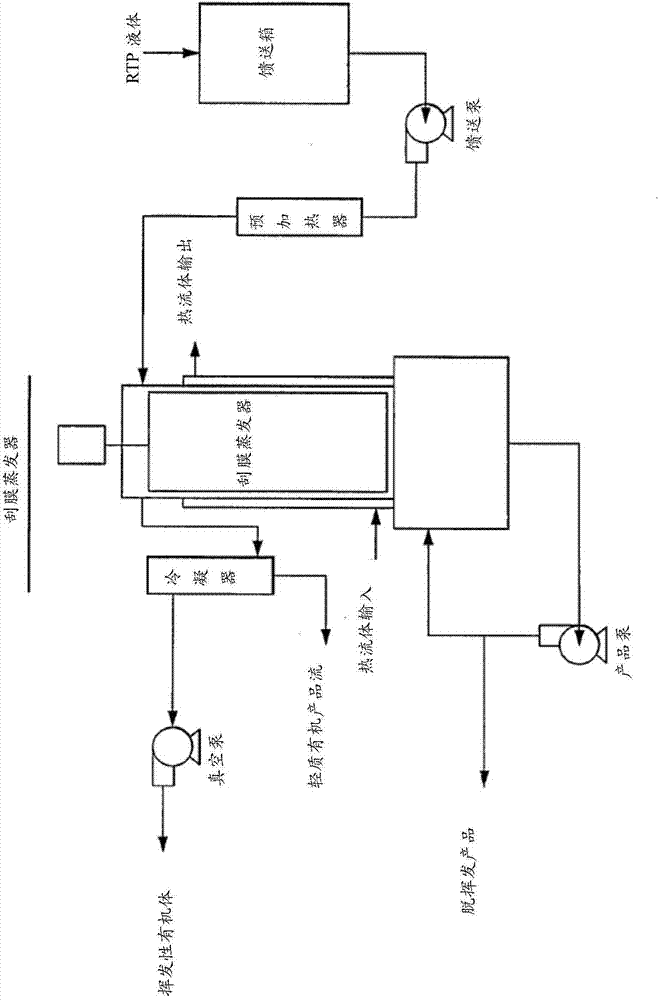

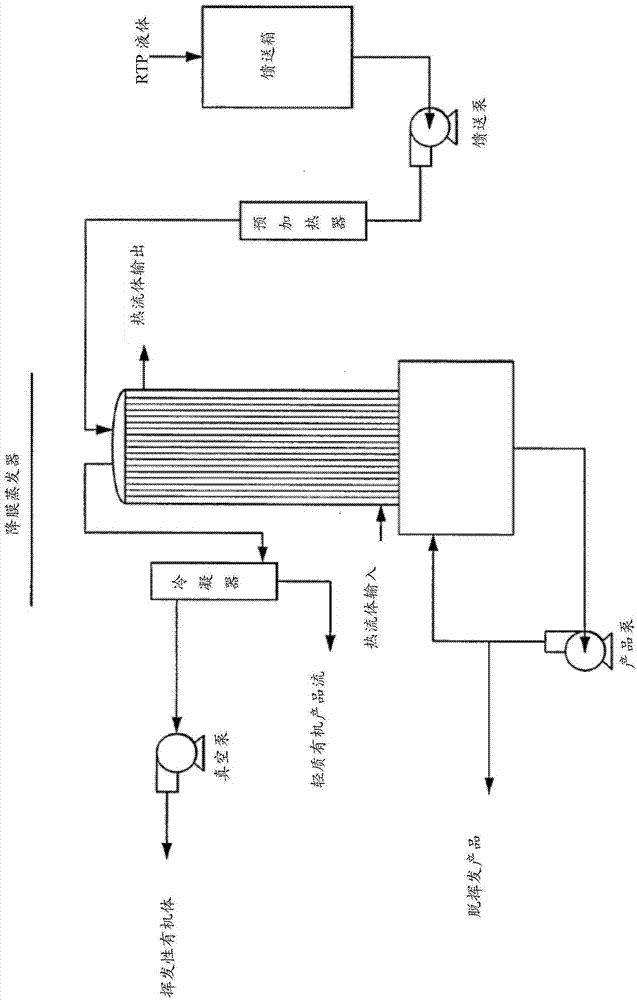

[0031]The present disclosure generally relates to the devolatilization of thermal liquids to increase the flash point. More specifically, the present disclosure is directed to methods and apparatus for effectively and selectively reducing the volatile content of liquids produced from thermal conversion of biomass and petroleum materials, thereby causing an increase in flash point.

[0032] A measure of the flash point of a liquid is a common measure of flammability and is indicated by the maximum temperature at which the material can be stored and handled. If the flash point is too low, it renders the liquid susceptible to flash and possible ignition. Certain properties of materials are generally not affected by changes in flash point, such as autoignition temperature, fuel injection, and combustion behavior. In many jurisdictions, there are significant differences in how materials are handled when their flashpoints are below a certain threshold. This threshold is typically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com