Sheet-shaped object cutting-off method

A sheet-like, knife-roller technology, applied in the directions of sending objects, function instructions, thin material processing, etc., can solve the problem of inability to accurately control the gap between the knife-roller and the anvil-roller in real time online, to improve safety and continuity, increase Service life, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

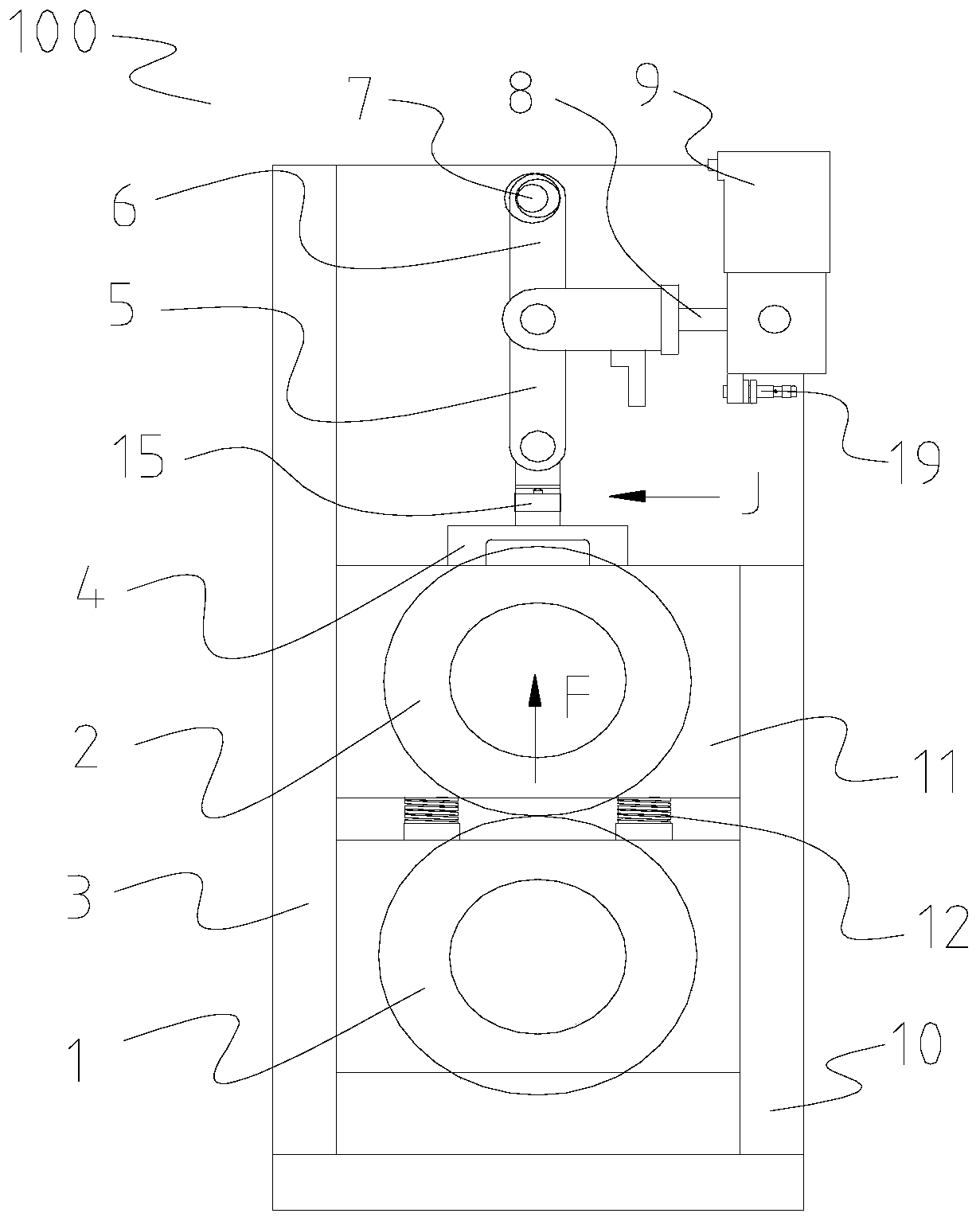

[0026] A method for cutting a sheet. While feeding the sheet between the knife roll 2 and the anvil roll 1, the knife roll 2 is rotated. During the rotation of the knife roll 2, it includes:

[0027] S1. Cutting process: In the cutting process, the knife roll 2 and the anvil roll 1 rotate relatively to cut off the sheet, and the sheet will generate a reaction force F to the knife roll during the cutting process.

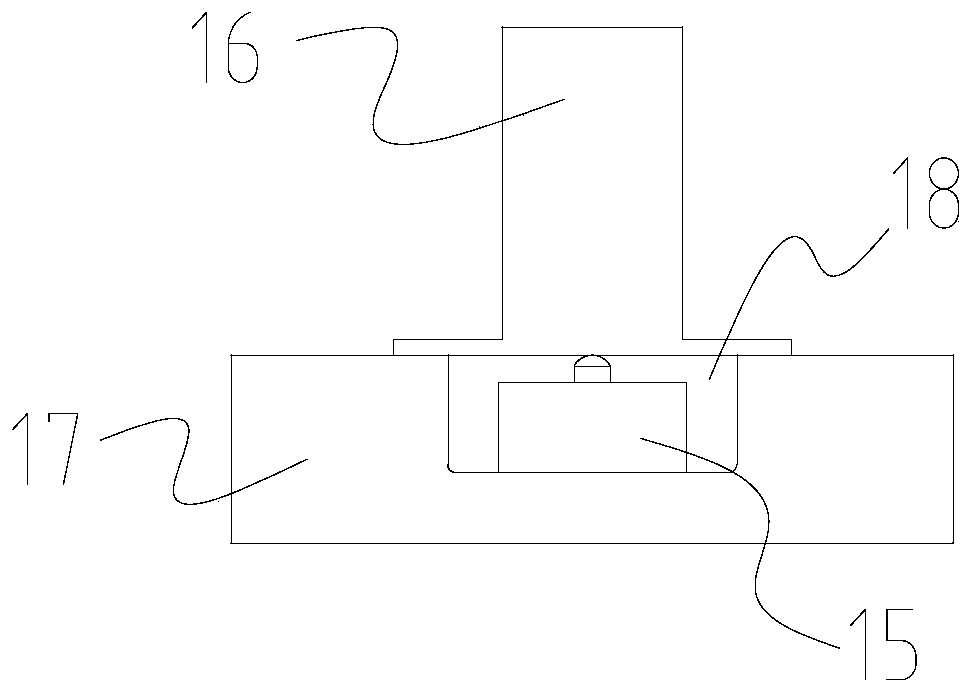

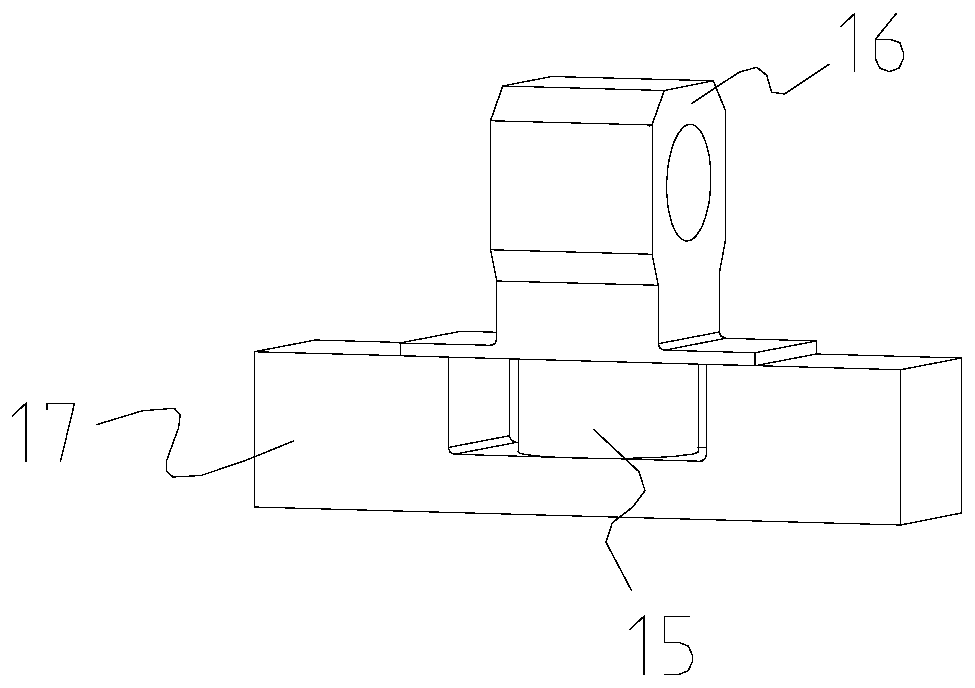

[0028] S2. Detection process: In the detection process, the pressure sensor senses the magnitude of the cutting force, and transmits the sensed value to the control system. Wherein, the pressure sensor 15 is installed between two connecting elements 16, 17, wherein one connecting element is installed on the lower toggle of the gap fine-tuning link mechanism, and the other connecting element is connected with the moving plate for fixing the knife roller. The knife roller exerts a cutting force on the sheet, and the corresponding sheet exerts a reaction force equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com