Floor grinding wheel and manufacturing method thereof

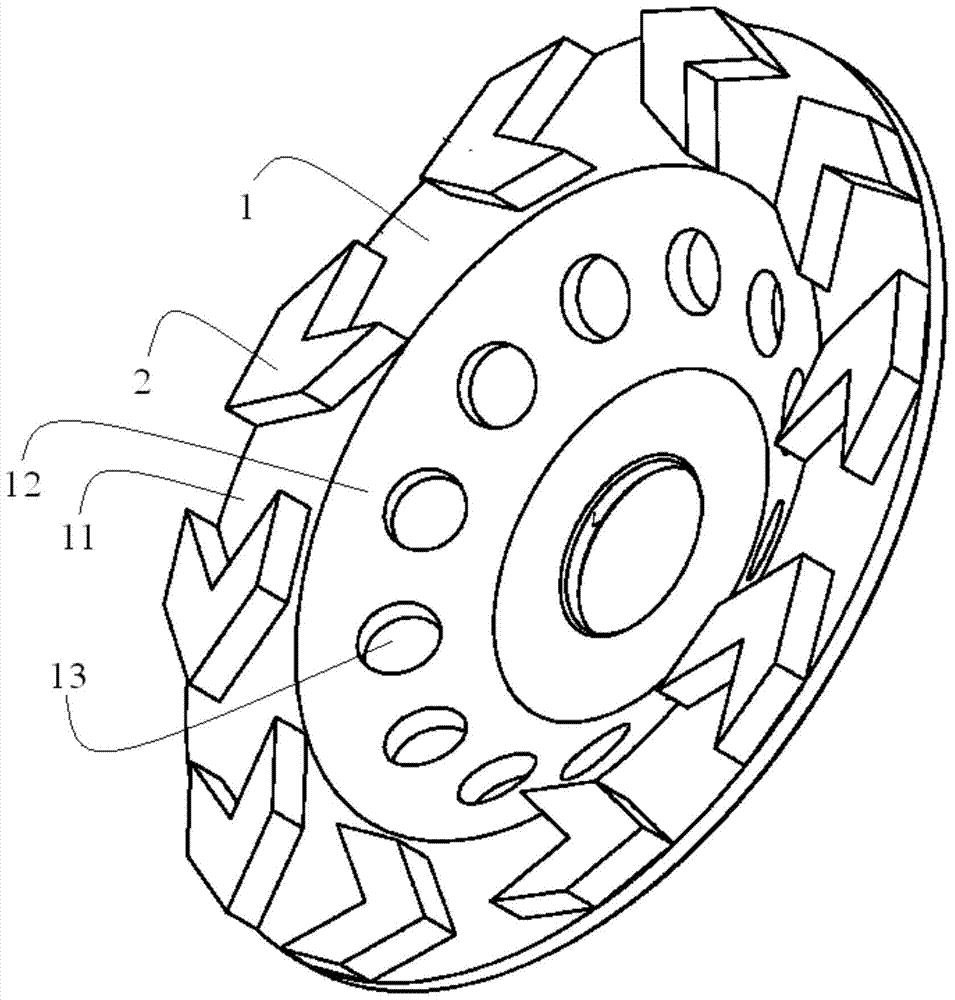

A grinding wheel and flooring technology, which is applied in the direction of manufacturing tools, abrasives, bonded grinding wheels, etc., can solve the problems that the floor coating is difficult to clear, and achieve the effect of ensuring smoothness, ensuring connection strength, and solving cleaning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Adopt mechanical mixing method to mix matrix powder and diamond particle for 1h to make it uniform, so as to obtain mixed powder; The volume of ~50 mesh diamond particles accounts for 50% of the total volume of the diamond particles, and the diamond concentration is 35%; the matrix powder is composed of the following components by weight percentage: pre-alloyed powder FeCuCoSnTiCr: 55%, Ni: 5%, Cu : 30%, Sn: 9%, graphite powder: 1%; the weight percentage content of each element in the pre-alloyed powder FeCuCoSnTiCr is: Fe: 69%, Cu: 10%, Co: 13%, Sn: 7% , TiCr alloy (in TiCr alloy, Ti: 50wt%, Cr: wt% 50): 1%. The FeCuCoSnTiCr pre-alloyed powder is first prepared by a conventional water atomization method, and then the above matrix powder is prepared by a conventional water atomization method.

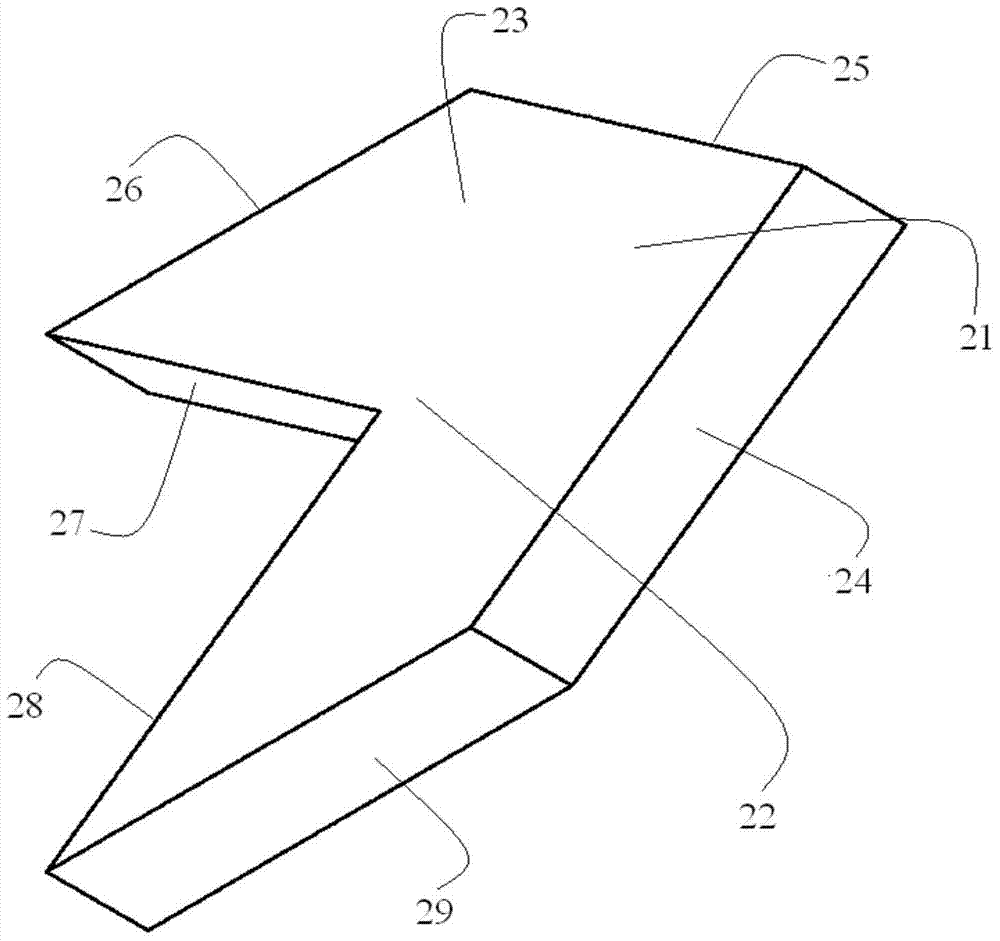

[0048] In the hooking processing step, the hooking on the outer surface of the base is processed on the pre-substrate by using a drill to drill holes and remove the burrs. ...

Embodiment 2

[0056] Except that the component content of the carcass powder is different from that of Example 1, other steps are the same as in Example 1. The composition content of the matrix powder in this embodiment is: pre-alloyed powder FeCuCoSnTiCr: 50%, Ni: 10%, Cu: 25%, Sn: 10%, graphite powder: 5%.

[0057]The properties of the 10 floor grinding wheels obtained in this embodiment were tested, and the specific properties are shown in Table 2.

[0058] Table 2 head performance

[0059]

[0060] During the use of the 10 floor grinding wheels in this embodiment, there is no phenomenon of cutter head falling off, chips can be removed smoothly, and there is no phenomenon that the floor grinding wheels cannot be used due to the inability to remove chips. The surface of the workpiece has no burrs, no scratches, no fog and chatter marks.

Embodiment 3

[0062] Except that the component content of the carcass powder is different from that of Example 1, other steps are the same as in Example 1. The composition content of the matrix powder in this embodiment is: pre-alloyed powder FeCuCoSnTiCr: 60%, Ni: 6%, Cu: 24%, Sn: 9%, graphite powder: 1%.

[0063] The properties of the 10 floor grinding wheels obtained in this embodiment were tested, and the specific properties are shown in Table 3.

[0064] Table 3 head performance

[0065]

[0066] During the use of the 10 floor grinding wheels in this embodiment, there is no phenomenon of cutter head falling off, chips can be removed smoothly, and there is no phenomenon that the floor grinding wheels cannot be used due to the inability to remove chips. The surface of the workpiece has no burrs, no scratches, no fog and chatter marks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com