Fixed length control system

A control system and fixed-length technology, applied to rotary printing machines, printing, printing devices, etc., can solve problems affecting normal use, pattern deformation, film elongation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

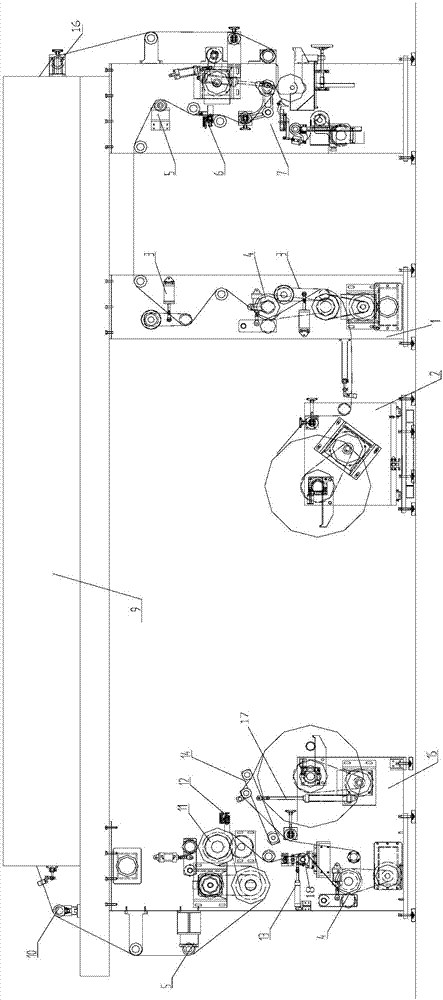

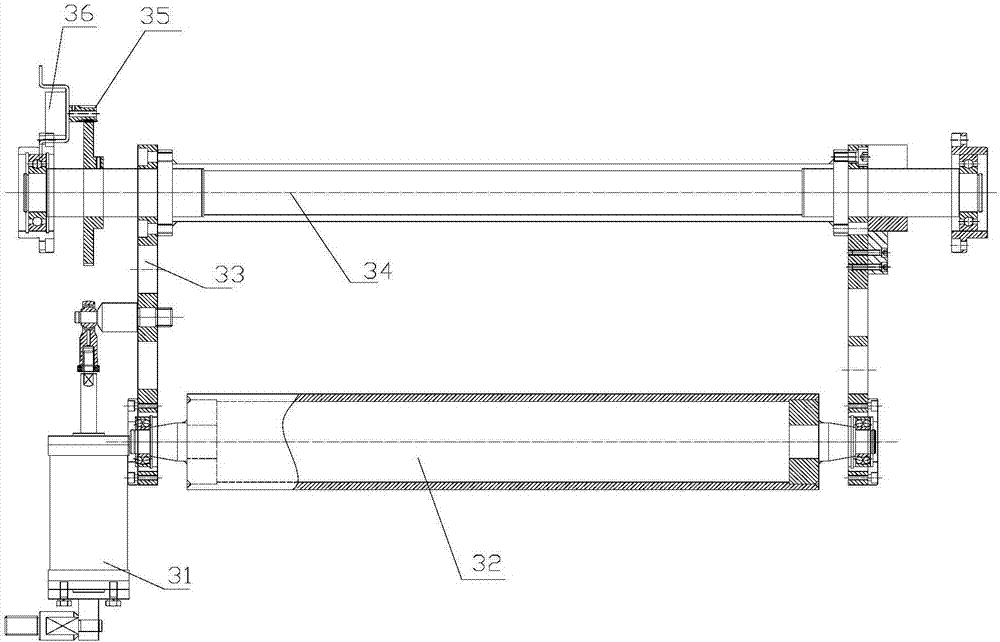

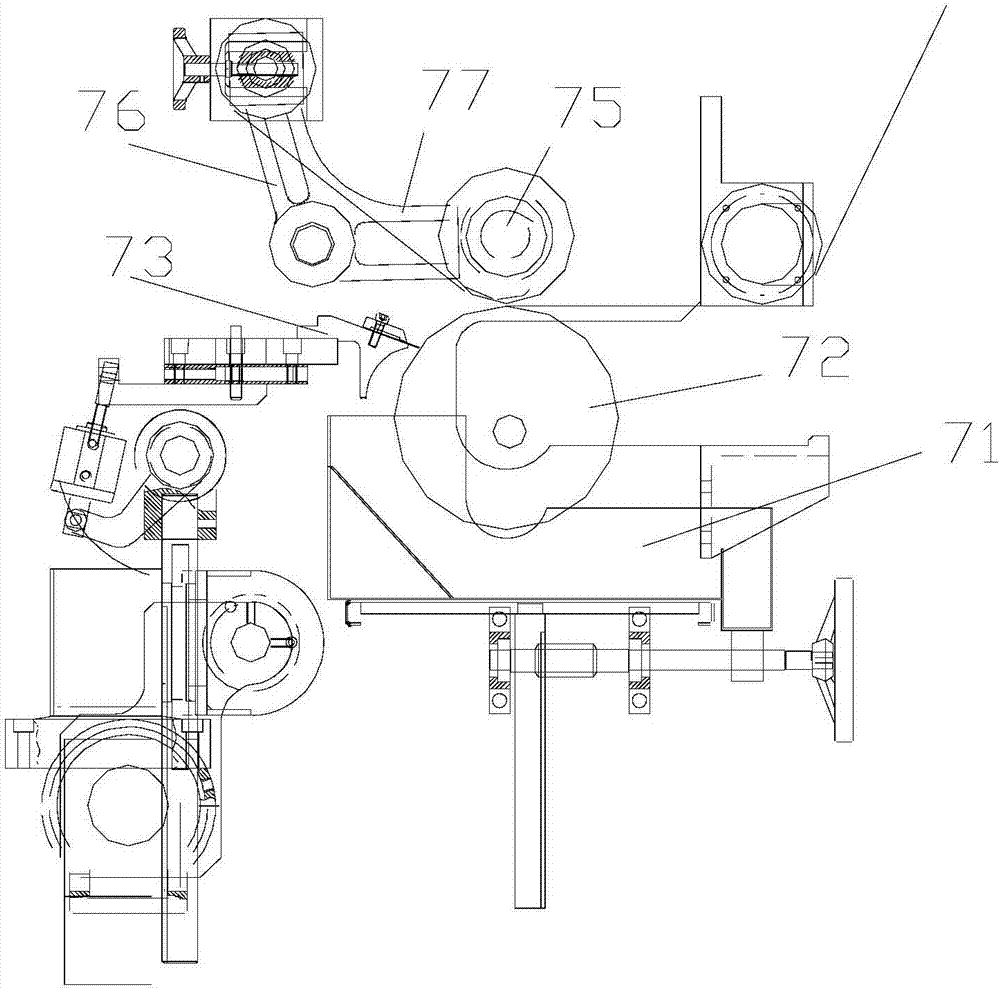

[0032] Such as Figure 1-7 As shown, a fixed-length control system includes a frame 1, an unwinding device 2, a traction device 4, a swing arm type tension adjustment device 3, a drying device 7, a traction cooling mechanism and a winding device 15; the frame 1 is fixed on the base, and the frame includes two side plates arranged in parallel; the swing arm type tension adjustment device 3 includes an adjustment guide roller 32, an adjustment shaft 34, an adjustment cylinder 31, a potentiometer 36 and two adjustment pendulums Arm 33, the two ends of adjustment shaft 34 are rotated and arranged on the both sides of the frame 1, one end of two adjustment swing arms 33 is fixedly connected with adjustment shaft 34, the two ends of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com