Display device and electronic equipment

A technology for display devices and fixed casings, applied in identification devices, mechanical equipment, transmission devices, etc., can solve problems such as inability to fit flexible screens, affect screen flatness, and slippage between flexible screens and shaft surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

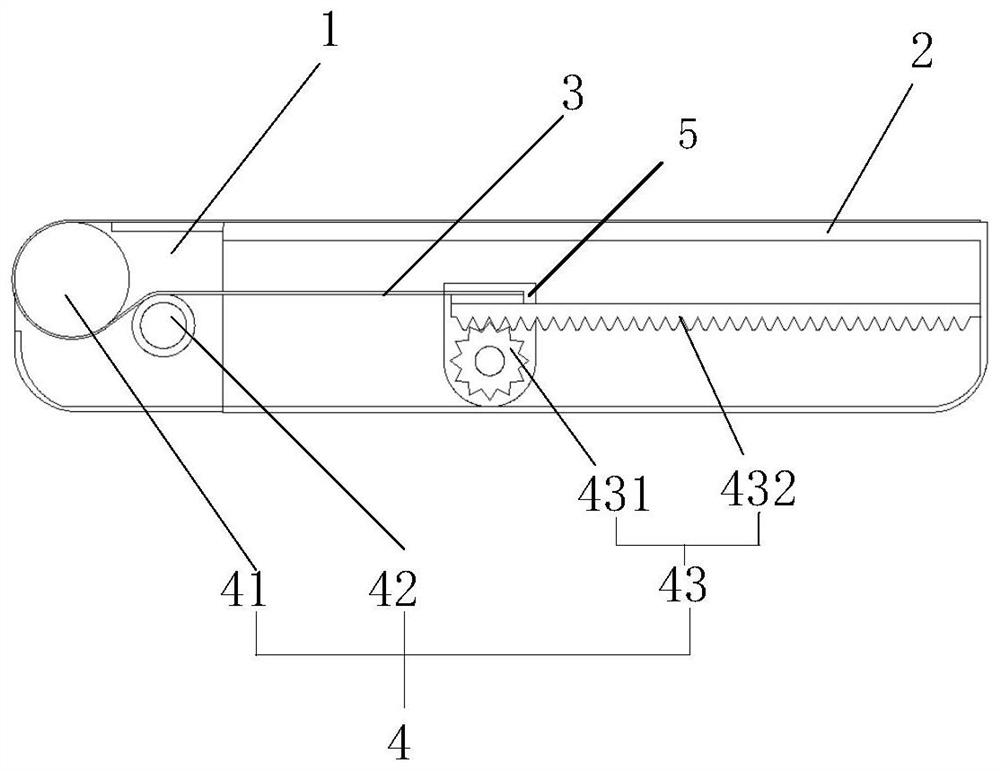

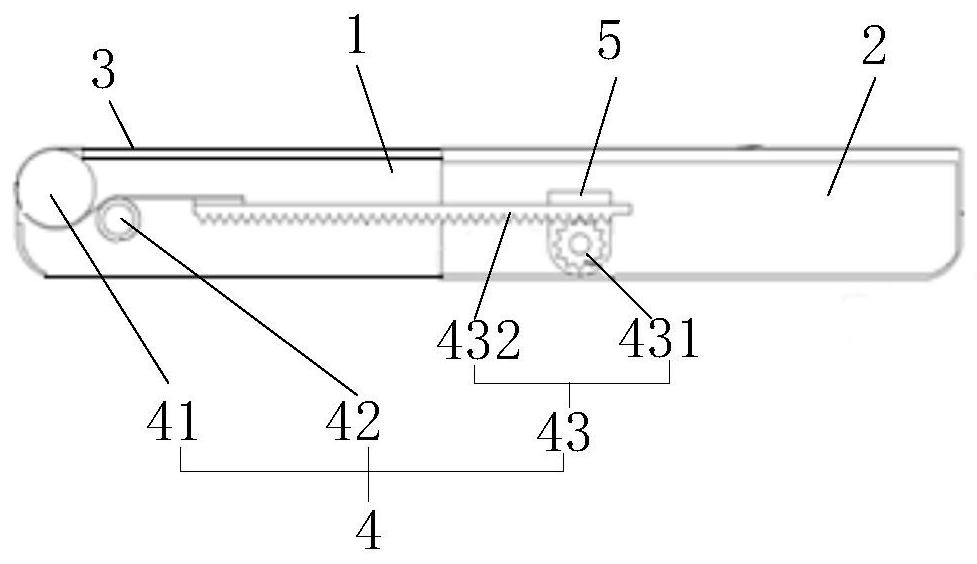

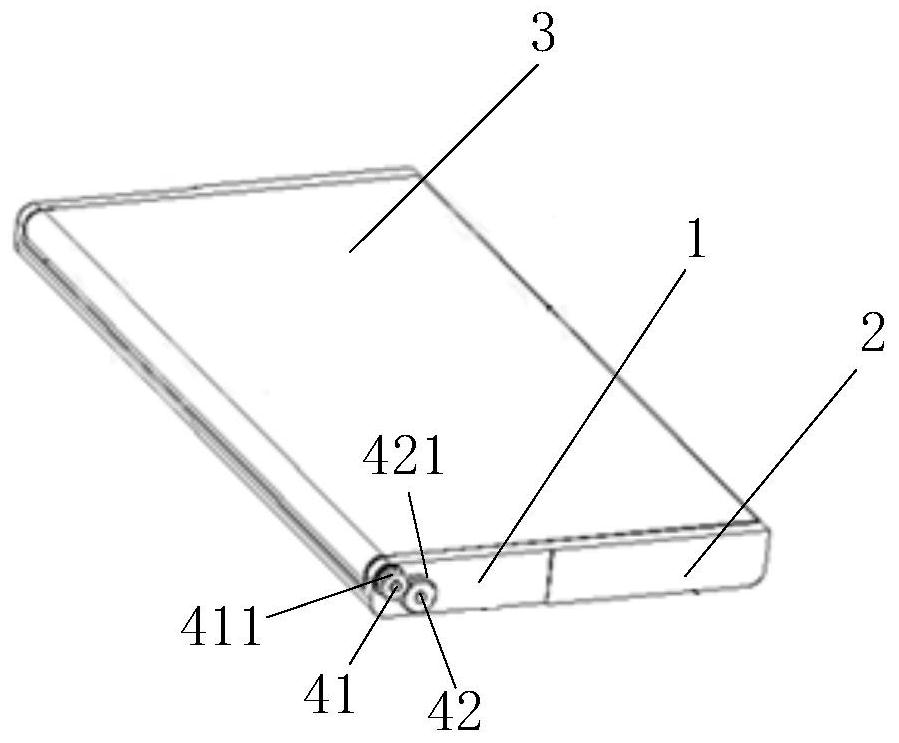

[0041] Embodiment 1 of the present invention provides a display device, referring to Figure 1 ~ Figure 2 , showing a schematic structural view of a display device of the present invention, such as Figure 1 ~ Figure 2 As shown, the display device includes a sliding casing 1, a fixed casing 2, a flexible screen 3 and a transmission assembly 4; the sliding casing 1 and the fixed casing 2 are slidably connected; the transmission assembly 4 includes a roller 41, a pretension shaft 42, The transmission part 43; the transmission part 43 is fixed inside the fixed casing 2, the first end of the flexible screen 3 is fixed on the fixed casing 2, the flexible screen 3 covers the top outer surface of the fixed casing 2, and the second end of the flexible screen 3 The end is wound around the roller 41 and fixed on the transmission member 43 , the pretension shaft 42 is located between the roller 41 and the transmission member 43 , and the top outer surface of the pretension shaft 42 press...

Embodiment 2

[0071] Embodiment 2 of the present invention also provides an electronic device, the electronic device includes the display device described in any one of the above implementations, the beneficial effect of the electronic device is consistent with the beneficial effect of the above display device, and the embodiment of the present invention is This will not be repeated here.

[0072] It should be noted that the electronic device may be: a mobile phone, a tablet computer, an e-book reader, an MP3 player, an MP4 player, a laptop computer, a vehicle computer, a desktop computer, a set-top box, a smart TV or a wearable device , which is not limited in this embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com