Joint control device and method for low waterhead Kaplan turbine

It is a synergistic regulation and paddle-rotating technology, which can be used in safety devices, mechanical equipment, hydropower, etc., and can solve the problems of reduced guide vane opening, reduced downtime and transition time, and reduced unit stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

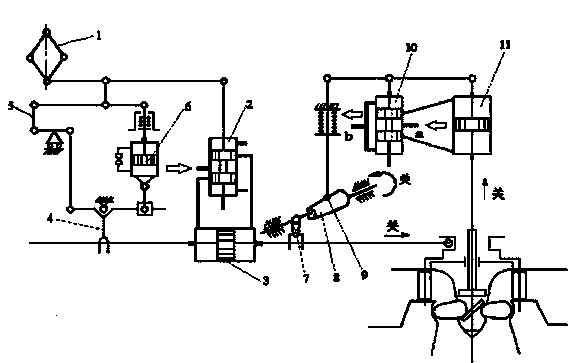

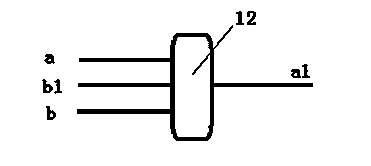

[0018] Such as figure 1 , 2 As shown in the figure, a low-head rotary paddle turbine association regulating device, the oil supply pipe a of the vane pressure distribution valve 10 is connected to the oil supply oil circuit a1 through the two-way connection of the four-way reversing valve 12, and the oil supply pipe a of the vane pressure distribution valve 10 The oil return pipe b and the oil return circuit b1 are connected through the other two ports of the four-way reversing valve 12. Controlling the valve plate of the four-way reversing valve 12 can make the oil supply pipe a of the vane pressure distribution valve 10 and the oil return circuit b1 two-way. The oil return pipe b is in two-way communication with the oil supply oil passage a1, and the four-way reversing valve 12 can also be controlled so that the oil supply pipe a of the vane pressure distribution valve 10 is in two-way communication with the oil supply oil passage a1, and the vane pressure distribution The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com