Sealing means between rotor and housing in a water turbine

A water turbine and rotor technology, applied in engine sealing, mechanical equipment, hydroelectric power generation, etc., can solve problems such as loss, large gap, loss sealing, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

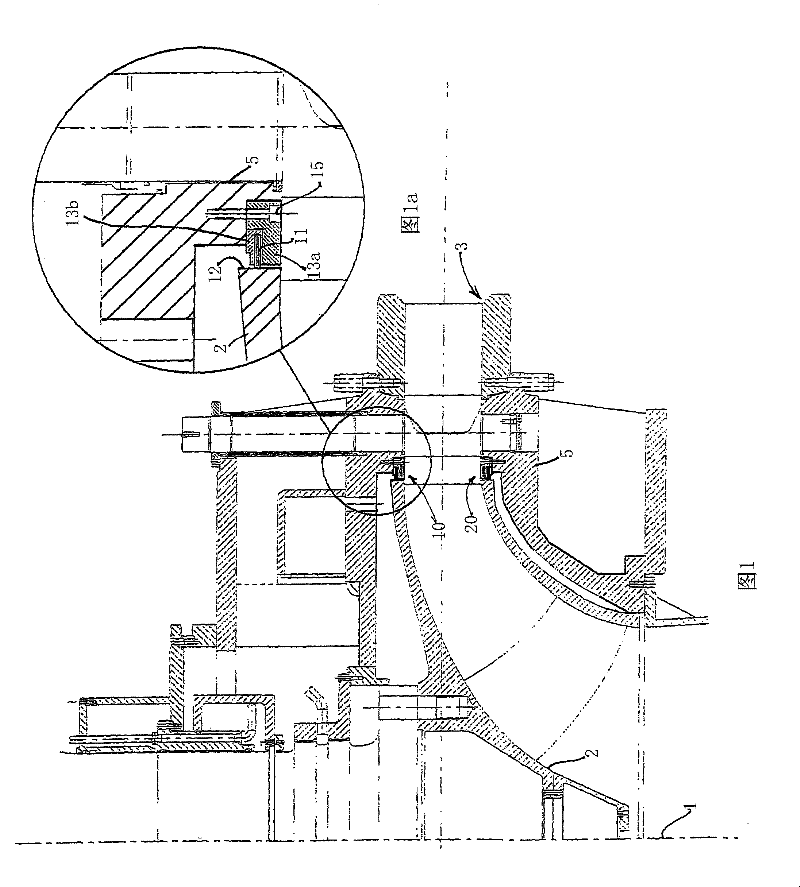

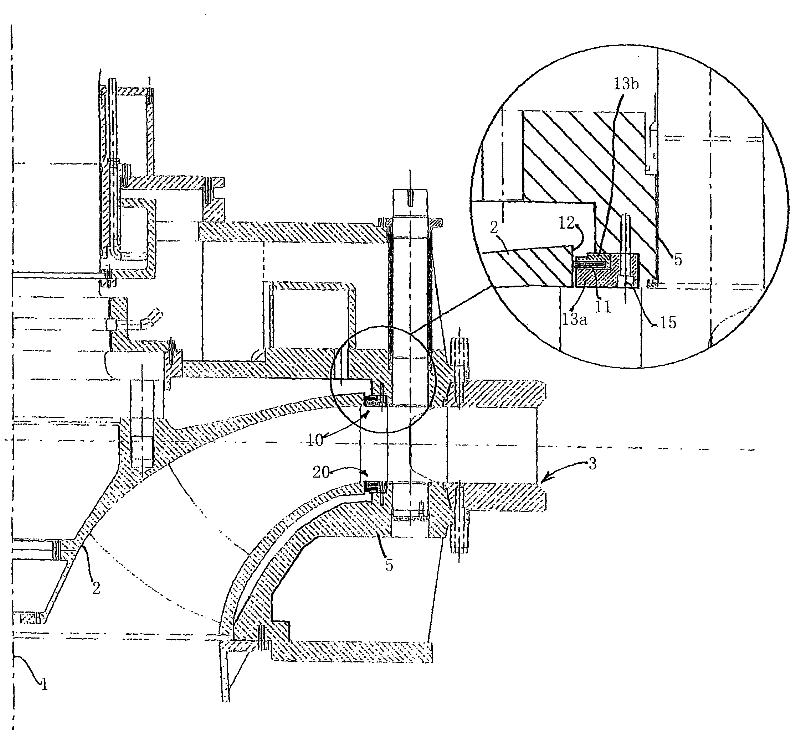

[0018] As is conventional, the shown turbomachine comprises a rotor 2 with an axis of rotation 1 , which in this example is vertical, ie perpendicular to the axis of rotation 1 . A housing structure 5 surrounds the rotor and includes guide vane ducts 5 for directing water towards the rotor 2 . This water should be prevented as much as possible from escaping in the gap between the housing part of the rotor and the immediately adjacent part. For this purpose, seals as indicated at 10 and 20 are provided.

[0019] Seal 10 in Figure 1a shown in more detail. The seal 20 has a corresponding design. Therefore, in Figure 1a In the rotor 2 and adjacent parts of the housing 5 are shaped to accommodate a seal 10 in the form of a brush seal, the main component of which is essentially a brush or bristle assembly 11 . It is mounted between the clip members 13a and 13b so that the protruding bristle ends abut against the radially outward outer end face 12 at the circumference of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com