Kaplan turbine blade operating mechanism

An operating mechanism and water turbine technology, applied in the direction of machines/engines, mechanical equipment, hydroelectric power generation, etc., can solve the problems of poor casting process, large quantity, and difficult design of parts and runners, and achieve shortened design and manufacturing cycle, low cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

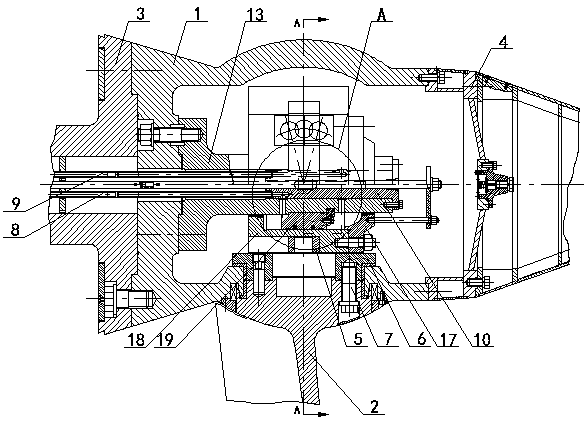

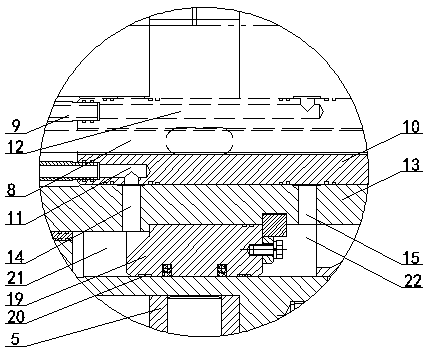

[0019] Embodiment 1: as figure 1 , 2 As shown in . and 3, a paddle turbine blade operating mechanism includes a runner body 1, at least three blades 2 are arranged on the runner body 1, and water turbines are respectively arranged at both ends of the runner body 1. The main shaft 3 and the drain cone 4 are provided in the runner body 1 with an operating oil pipe whose end passes through the main shaft 3 of the water turbine and penetrates into the runner body 1, and an oil inlet and outlet mechanism is arranged on the penetrating end of the operating oil pipe. A super relay mechanism communicating with the oil inlet and outlet mechanism is arranged on the oil inlet and outlet mechanism, and the super relay mechanism is connected with the blade 2 through the slider 5 and the rocker arm 6 .

[0020] Wherein, the operating oil pipe includes the operating oil pipe A8 and the operating oil pipe B9; the oil inlet and outlet mechanism includes the oil receiving shaft 10, and the oil...

Embodiment 2

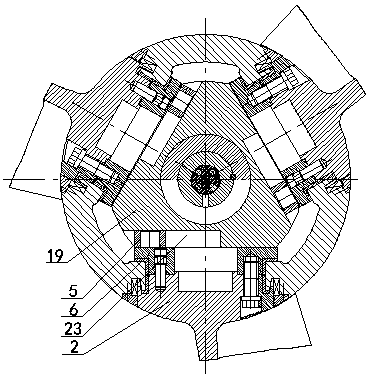

[0026] Embodiment 2: as Figure 4 As shown, the section of the super servomotor cylinder 18 is square, and four chutes 23 are evenly arranged on the super servomotor cylinder 18; Inside the chute 23 ; there are four blades 2 , and each slider 5 is connected to the corresponding blade 2 through a rocker arm 6 .

Embodiment 3

[0027] Embodiment 3: as Figure 5 As shown, the section of the super servomotor cylinder 18 is pentagonal, and five chutes 23 are evenly arranged on the super servomotor cylinder 18; There are five slide slots 23; there are five blades 2, and each slider 5 is connected to the corresponding blade 2 through a rocker arm 6, respectively.

[0028] Of course, according to actual needs, the super servomotor cylinder 18 can also be made into a hexagonal or octagonal shape, and the corresponding blades 2 can also adopt six blades or eight blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com