Blade electro-hydraulic adjustment method and device of high-oil-pressure control water turbine

An electro-hydraulic regulation and water turbine technology, which is applied in the directions of hydropower generation, safety devices, mechanical equipment, etc., can solve the problems of polluting the environment, complex structure of the oil receiver, and frequent starting of the oil pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

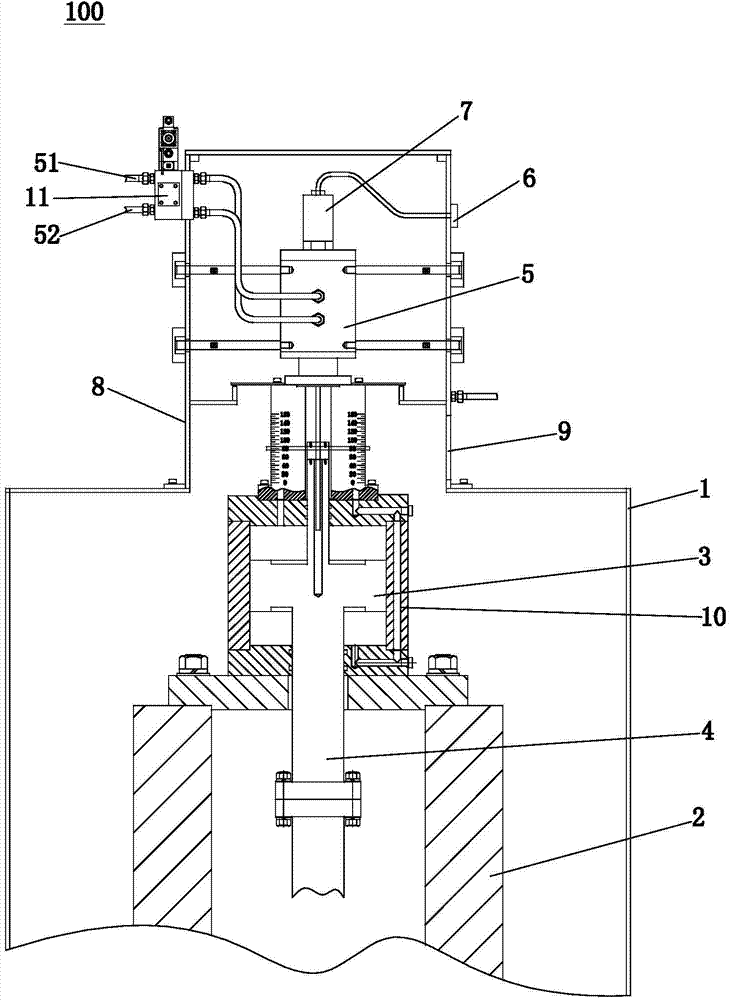

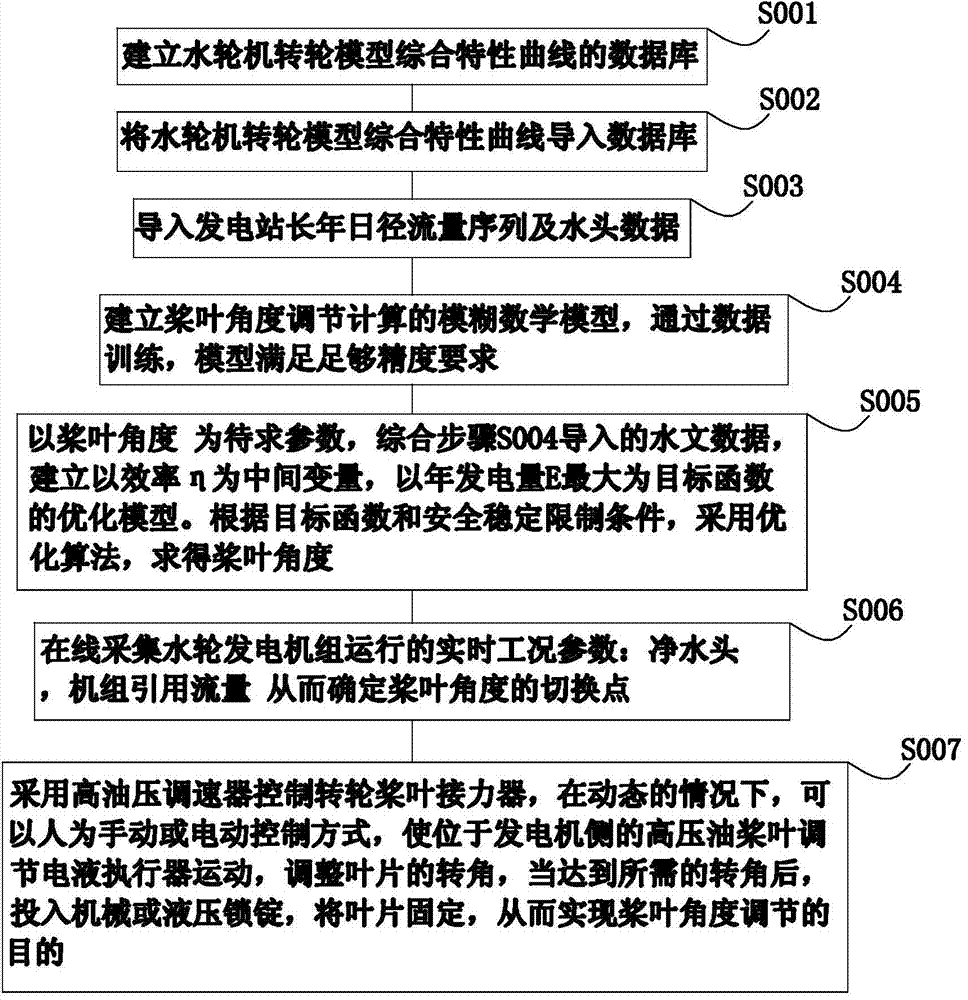

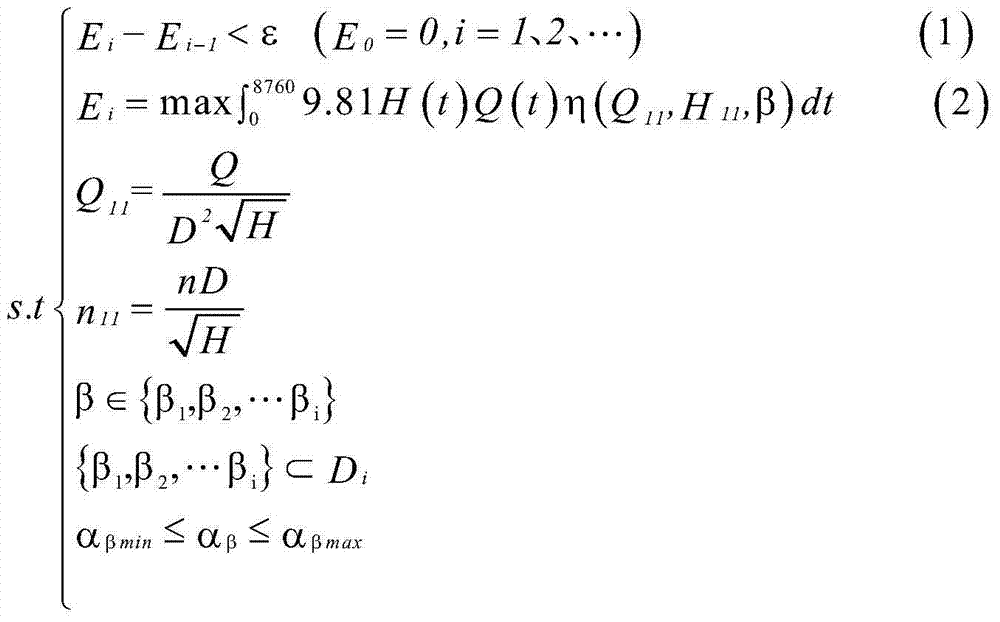

[0043] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 , 2 As shown, the present invention provides a blade electro-hydraulic adjustment device 100 of a high oil pressure control turbine, such as figure 1 Shown includes: generator casing 1, unit main shaft 2, piston 3, operating rod 4, oil circuit manifold 5, displacement sensor line 6, displacement sensor 7, adjustment device cover 8, observation hole 9, blade servomotor 10, Solenoid valve group 11, the blade servomotor 10 is fixed on the main shaft 2 of the unit, the piston 3 is fixed on the operating rod 4, and rotates simultaneously with the main shaft 2 of the unit, and the piston 3 is operated by hydraulic oil to drive the blades Rotate, the oil integrated block 5 is fixed on the generator casing 1, does not rotate with the main shaft 2 of the unit, the oil pipeline of the oil integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com